The aim of nanoparticle self-assembly research has been to get the particles to organize themselves into structures that are largely controlled by us. However, the level of control we have sought has sometimes left a little bit to be desired.

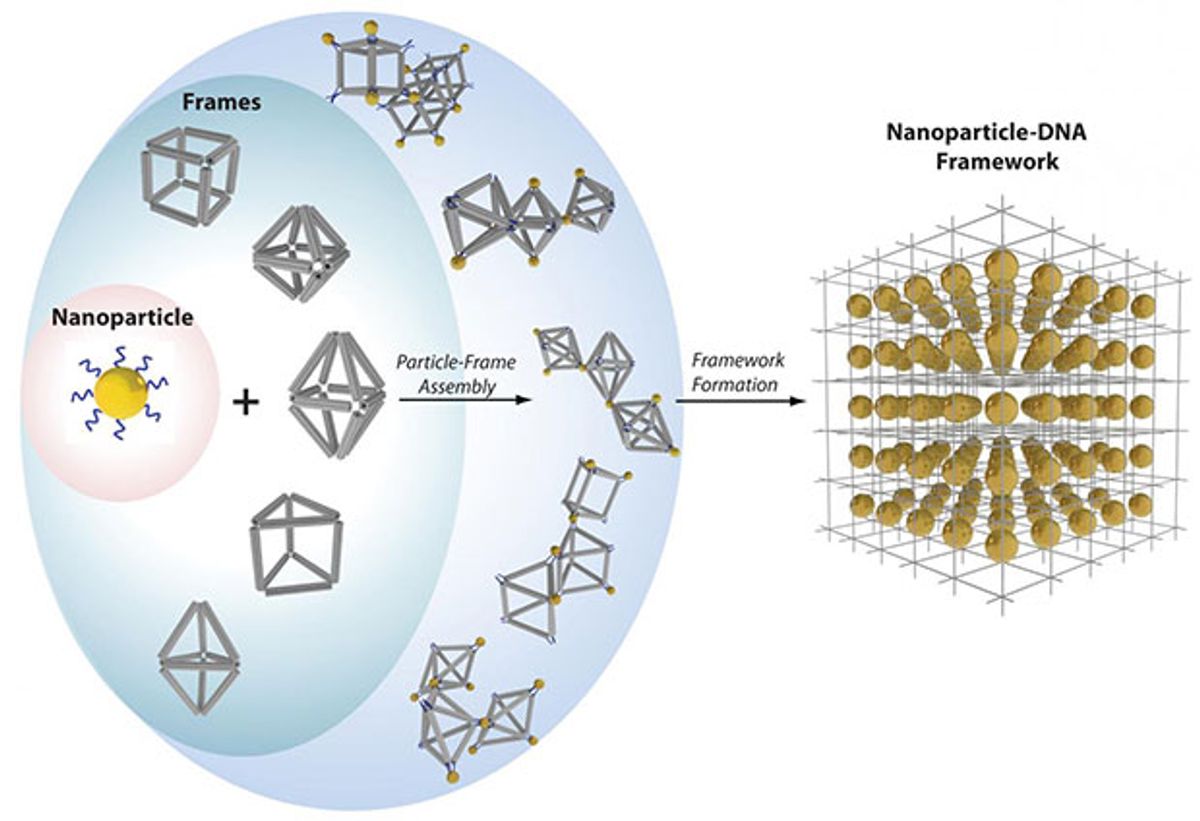

Now, researchers at the U.S. Department of Energy's (DOE’s) Brookhaven National Laboratory have demonstrated that polyhedral structures made from DNA can serve as a framework for ensuring that the nanoparticles self-assemble in the exact arrangement their minders intended. In these DNA structures, the nanoparticles can be assembled into crystalline and open 3-D frameworks that themselves can be interconnected, making possible a wide variety of different structures.

“We are aiming to create self-assembled nanostructures from blueprints,” said Oleg Gang, who led this research, in a press release. “The structure of our nanoparticle assemblies is mostly controlled by the shape and binding properties of precisely designed DNA frames, not by the nanoparticles themselves,” Gang said.

It would seem that the Brookhaven researchers see this work as a step towards the long-promised aim of “materials by design” in which a material can be designed and fabricated with a very specific purpose—and therefore, specific optical, electric and magnetic properties—in mind. Gang added:

By enabling us to engineer different lattices and architectures without having to manipulate the particles, our method opens up great opportunities for designing nanomaterials with properties that can be enhanced by precisely organizing functional components. For example, we could create targeted light-absorbing materials that harness solar energy, or magnetic materials that increase information-storage capacity.

In research described in the journal Nature Materials, the Brookhaven researchers leveraged the base pairing of DNA, by putting single-strand DNA tethers in the polyhedral structures made out DNA. Thus far, the resulting structures include a cube, an octahedron, an elongated square bipyramid, a prism, and a triangular bipyramid. When the researchers mix the nanoparticles that have the DNA strands attached to them with the DNA structures, the nanoparticles attach to the place in the lattice structure with a complementary strand.

“In our approach, we use DNA frames to promote the directional interactions between nanoparticles such that the particles connect into specific configurations that achieve the desired 3D arrays,” said Ye Tian, lead author on the Nature Materials paper and a member of Gang's research team, in a press release. “The geometry of each particle-linking frame is directly related to the lattice type, though the exact nature of this relationship is still being explored.”

The geometry of the connections between the polyhedral structures and the nanoparticles are integral to the properties and functions of the resulting material. If the researchers want to design a material that is particularly good at collecting light or for producing display screens, they arrange optically active nanoparticles in a particular geometry so that it can filter, absorb and emit light. Said Gang:

Although many additional studies are required, our results show that we are making advances toward our goal of creating designed matter via self-assembly, including periodic particle arrays and complex nanoarchitectures with freeform shapes. Our approach is exciting because it is a new platform for nanoscale manufacturing, one that can lead to a variety of rationally designed functional materials.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.