There is a fairly large number of materials that might have some pretty attractive properties if they could be made into monolayer, two-dimensional (2-D) sheets. Unfortunately, unlike graphene, which is fabricated by peeling away layers from bulk graphite, these other materials don’t have a multi-layered source. But now the fabrication of these materials has become a possibility through a novel “bottom-up” production technique whose development may have just changed the future of 2-D materials in electronics.

Researchers at the University of Wisconsin-Madison (UW-Madison) have developed a technique in which a zinc oxide monolayer self assembles in a liquid with the help of a surfactant. After six years of trial-and-error testing with different surfacants, the UW-Madison researchers believe they have found the right mix.

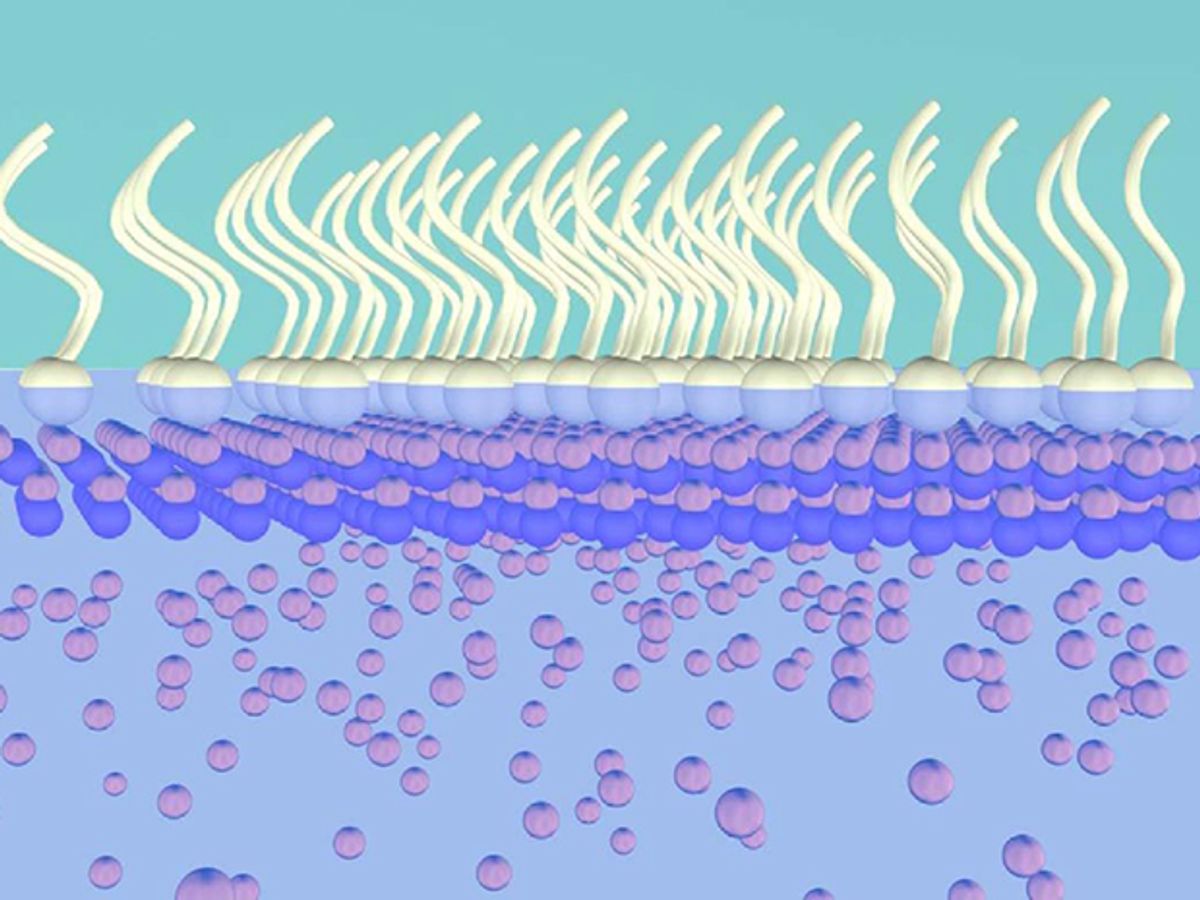

In research explained in a paper published in the journal Nature Communications, the researchers discovered that when a surfactant—essentially a detergent—containing sulfate ions was placed in a liquid containing zinc ions, it would trigger the self-assembly of zinc oxide nanosheets. The negatively charged sulfate ions in the surfactant attract the positively charge zinc ions, and within a couple of hours, the 2-D zinc oxide is formed.

The idea for this approach came to Xudong Wong, one of the authors of the paper, while teaching a class on nanotechnology back in 2009.

“Under the correct conditions, a surfactant will self-assemble to form a monolayer,” said Wong, in a press release. “This is a well-known process that I teach in class. So while teaching this I wondered why we wouldn't be able to reverse this method and use the surfactant monolayer first to grow the crystalline face.”

In tests, the researchers discovered that the zinc oxide monolayers are able to function as p-type semiconductor transistors in which holes represent the majority of carriers and electrons are the minority. Just to give you a sense of how making zinc oxide down a 2-D material changes its properties, it’s important to know that in its bulk form, zinc oxide is an n-type semiconductor. Producing p-type semiconductors from zinc oxide has been the aim of much research.

Despite the breakthrough for zinc oxide production in two-dimensions, the real impact of this research may be that it opens the door for the production of fairly wide range of other 2-D materials that were not possible previously. To this end, the researchers are already looking at using their bottom-up surfactant technique to produce 2-D versions of gold and palladium. Wang added, in the press release: “It brings a lot of new functional material to this 2-D material category.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.