THE INSTITUTE The plastic plague in Nigeria, like in many other countries, is visible and inescapable. Even moderate rain showers in Nigeria cause flooding because the drainage system is choked with trash, most of it bags and other items made from plastic, says Fela Akinse, who lives in the country’s largest city, Lagos.

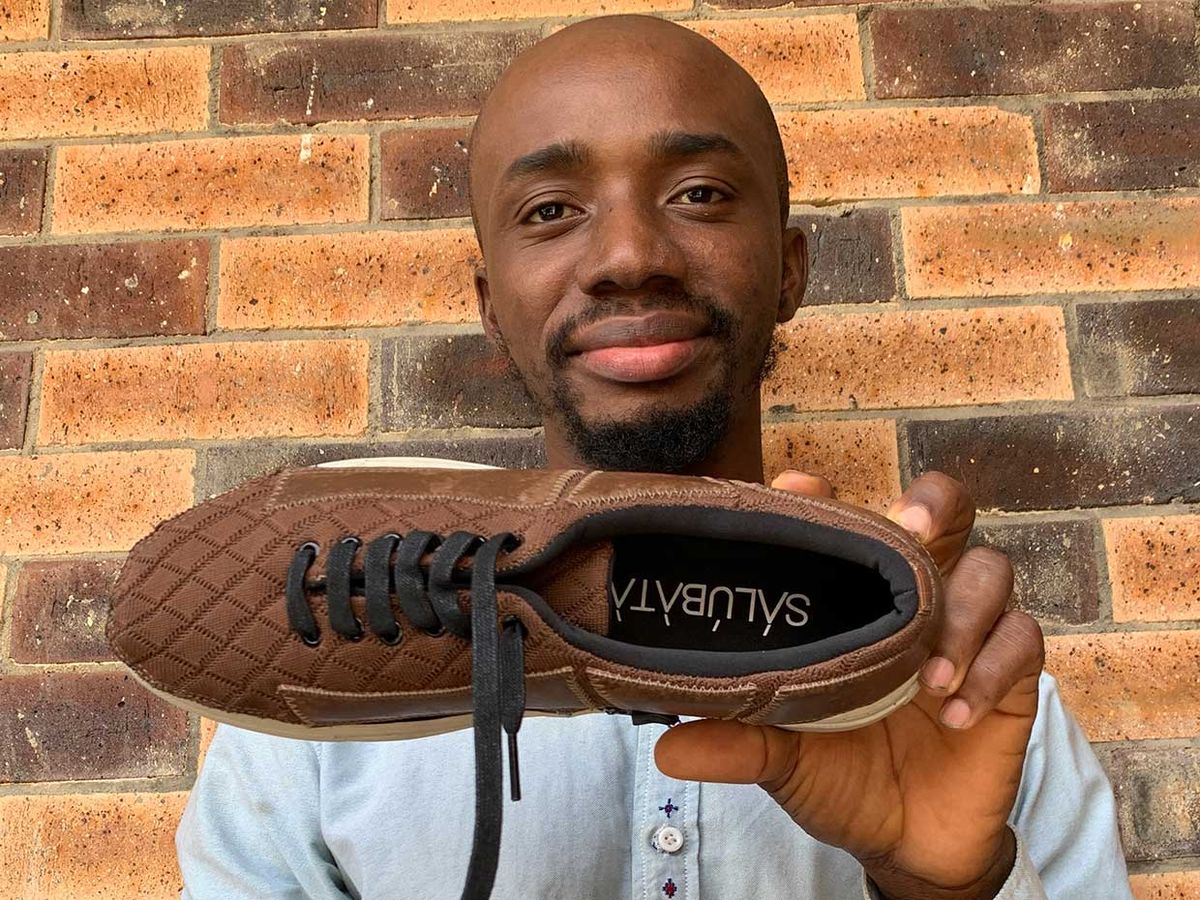

Akinse wants to tackle the plastic-pollution challenge, one shoe at a time. He is cofounder and creative director of Salubata, which designs and makes modular shoes from recycled plastic. The footwear uses a durable sole made of an algae-based foam. The interchangeable uppers are woven from plastic threads and attach to the soles with a zipper. By simply zipping on new uppers, wearers can swap styles and colors.

“Instead of you buying extra shoes, you can just have [several different] top flaps,” Akinse says, “so you have a full wardrobe of shoes that uses less material.”

In addition to taking up less closet space, Salubata’s patented footwear also saves room in a suitcase and reduces the luggage’s weight, making the shoes ideal for travel, he says. Simply pack a few different uppers to match your work and leisure outfits.

The Lagos-based startup was named an IEEE Entrepreneurship Star at this year’s virtual competition. The award recognizes ventures centered on engineering-driven innovation, aligning with IEEE’s core purpose: to foster technology, innovation, and excellence for the benefit of humanity. In addition to the recognition, awardees become honorary IEEE members for a year.

Salubata’s goal, Akinse says, is to help people and the planet: “I wanted to do something that impacts an everyday part of our lives. I’ve always seen plastic waste around me and have always looked for ways to help the environment.”

ENVIRONMENTAL CHAMPION

Akinse’s passion for the environment led him to study environmental toxicology at the University of Lagos, but he also had a keen fascination about the intersection of art and science. So besides his science classes, which he loved, he pursued dancing, clothing design, and other creative interests. “And now I’m in fashion,” he says. “It’s all about connecting the dots.”

He earned a bachelor’s degree in environmental toxicology in 2014 and, two years later, a master’s degree in environmental toxicology and pollution management from the university. For his master’s thesis project, he estimated the amount of polycyclic aromatic hydrocarbons—health-harming compounds found in crude oil and gasoline—in sediment and invertebrate creatures found at the bottom of the Lagos Lagoon.

He researched a novel crude oil remediation technique using iron oxide nanoparticles derived from seaweed. Oil spills are a major threat to marine ecosystems and human health, and the nanoparticles recently were found to be effective at removing oil from water. Making the nanoparticles typically involves harmful chemicals, and he was experimenting with a greener production method that used a seaweed extract instead.

All through school, Akinse’s interest in clothing and shoes tugged at him, so he designed leather shoes and accessories on the side. In 2012 he and his friend Adetona Omokanye—one of the company’s cofounders but then a photojournalist who was studying marine pollution and management at the university—started manufacturing and selling the products.

FASHION FORWARD

Akinse’s interests in the environment and fashion soon collided. He found out the average weight of shoes is around 0.5 kilograms, which is also the amount of plastic waste each U.S. citizen creates every day on average. Then he learned other staggering stats about the booming footwear market: On average, each American buys up to five pairs of shoes per year, and the global footwear industry produces about 30 billion pairs of shoes annually. Most of the shoes are made of petroleum-based plastics, foams, and rubbers.

On the flip side of the demand for new petroleum-derived material for shoes is the staggering amount of plastics that go to a landfill every year.

“In one year alone, over 381 million [metric tons] of plastic waste is produced around the world,” Akinse says. “And the sad part is only 9 percent of this waste is recycled. So we thought: Why can’t we convert plastic waste into shoes?

“The problem with plastic waste is the enormous volume. This could reduce the volume of plastic waste.”

Two years into his job as a scientist at World Environmental Systems, an engineering and consulting firm, he decided to quit and turn his full attention to building a sustainable-shoe business. He founded Salubata in 2018 with Omokanye and environmental scientist James Babalola.

They are not the first to think of making footwear from recycled plastic. Many shoe companies—including Adidas and other large brands, as well as newer companies such as Rothy’s—use recycled and sustainable materials. But their products tend to be expensive. So Akinse pursued the modular-shoe idea—which keeps costs low. He says the company also is differentiated by its shoe designs, which combine traditional African art with modern styles.

“We decided to occupy the niche for low-cost recycled-plastic shoes that benefit people and the planet,” he says. “Whether you’re environment-conscious or not, we wanted to make them appealing.

“The first thing we sell to customers is the design and modular idea. Not too many people really care about the environment, but if we get people to purchase these shoes, through that we can educate them about environmental issues.”

The company donates 5 percent of its profits to charitable causes that empower women and help children facing malnutrition.

IEEE CONNECTION

Salubata is now a seed-stage company with 11 employees including nine artisans in Lagos who make the shoes. Having bootstrapped so far, the company is seeking seed funding to scale up manufacturing and sell in major African cities and then Europe and the United States, Akinse says.

Salubata has sold around 1,500 sets—each set is one pair of soles plus two different uppers—mostly through its website. Its goal is to produce around 5 million such sets annually by 2023.

The company has garnered honors in addition to the recent IEEE award. The recognition has helped it gain funding and customers. The big benefit of the IEEE honorary membership?

“You interviewing me right now,” Akinse says. “The IEEE is a large network of intelligent, well-connected people. We believe it’s a big opportunity to easily connect to different communities.”

IEEE membership offers a wide range of benefits and opportunities for those who share a common interest in technology. If you are not already a member, consider joining IEEE and becoming part of a worldwide network of more than 400,000 students and professionals.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.