Nearly four years ago, I wrote an article about a prototype CPU cooler from Sandia Labs that used an innovative design. Even calling it a prototype might have been optimistic; research project would probably have been more accurate. But at CES this week, a company called CoolChip demonstrated a working commercial prototype, and a consumer version is just months away.

CPUs produce lots of heat when they’re working hard, and if you don’t move that heat somewhere else, the CPU will either shut itself down (if you’re lucky) or melt into a useless puddle of slag. And heat isn’t just a problem for consumer PCs. Datacenters have the same issue, except several orders of magnitude larger—and that gets very expensive.

The conventional method of removing heat from a CPU is to glue the CPU die directly onto a big piece of metal (like copper) that conducts heat well, sculpt that metal into ancient and mystical shapes that incorporate as much surface area as the laws of physics allow, and then slap a giant fan or two onto everything and move cool air across the system as efficiently as you can. Here’s an example of what a typical CPU cooler for a gaming PC might look like (the CPU and motherboard would be way down at the bottom underneath everything):

This method of cooling CPUs certainly works, but it’s not particularly efficient, and the cooling systems tend to be noisy and, as you can see, quite bulky.

A few years back, Sandia Labs was working on an idea for an entirely new type of CPU cooler called an “air bearing heat exchanger.” It was one of those things that was totally obvious if you thought about it: Why use a big structure with a lot of surface area and cooling fans to remove heat when you could just roll all their beneficial characteristics into one thing?

Awesome, right? There are lots of benefits to this design, including more robust cooling, higher efficiency, lower noise, and dust resistance. But Sandia isn’t in the business of making commerical products.

Fortunately, a startup from MIT called CoolChip is:

There was a bit of a kerfuffle over the exact nature of the relationship (or lack of relationship) between Sandia and CoolChip, but as of mid-2012, everything seems to have been worked out:

“The concept of using a thin air gap between the stationary and rotating components [of the cooling system] was developed and patented at Sandia National Labs. CoolChip has invested heavily in technology development beyond the original Sandia Labs concept with high-volume manufacturability, high-volume production pricing, and reliability considerations taken into account.”

At this point, it sounds like CoolChip has figured out all of the manufacturability and reliability stuff that’s necessary for a viable commercial product. They’ve partnered with Cooler Master to release a “kinectic cooling engine” that can cool a chip 50 percent more efficiently than a conventional cooler, in a form factor that’s half the size and emits much less noise. Seriously, this thing is quiet. The commercial product will look something like this:

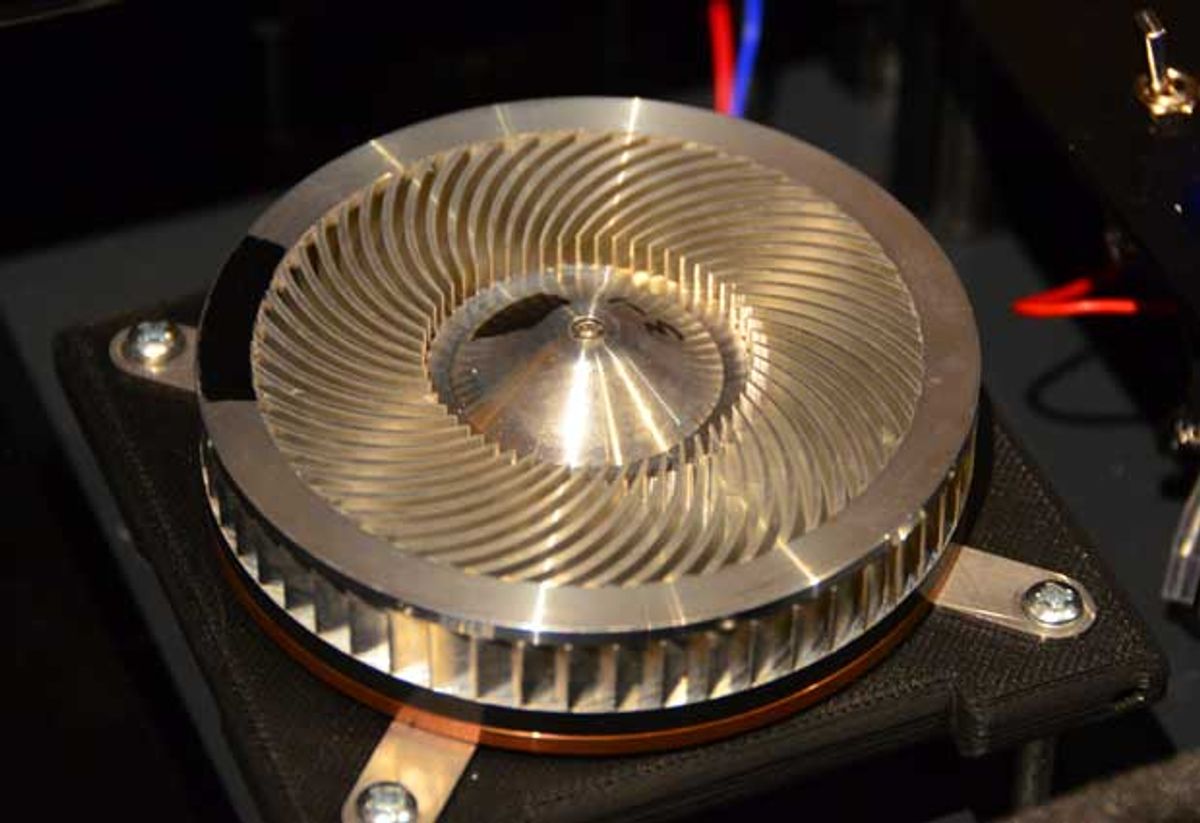

And here’s the heart of the pre-production prototype, showing the grooved base that mounts onto the CPU and transmits heat through the air bearing to the heat exchanger fan on top. The void in the fan is where the motor goes:

CoolChip’s Kinetic Cooling Engine, which should arrive later this year through Cooler Master, should be competitive in cost with other CPU cooling systems.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.