Carbon capture and sequestration (CCS) has made more headlines over the years for steps back than for steps forward. There have been a number of high profile projects that have been shelved or scaled down; American Electric Power, for example, cancelled big plans for a US $668 million facility in West Virginia, and the flagship FutureGen plant has now taken the form of a much diminished retrofit in Meredosia, Illinois. So news that what will be the biggest post-combustion carbon capture plant in the world has actually started construction is quite the anomaly.

The U.S. Department of Energy announced this week that the Petra Nova project has entered the construction phase; NRG Energy and JX Nippon are jointly retrofitting a coal-fired power plant near Houston so that 90 percent of the plant’s carbon emissions will be captured. This began as a 60-megawatt capture project with DOE support to the tune of $167 million, but the other sponsors expanded it to capture emissions from 240 MW of electricity generation.

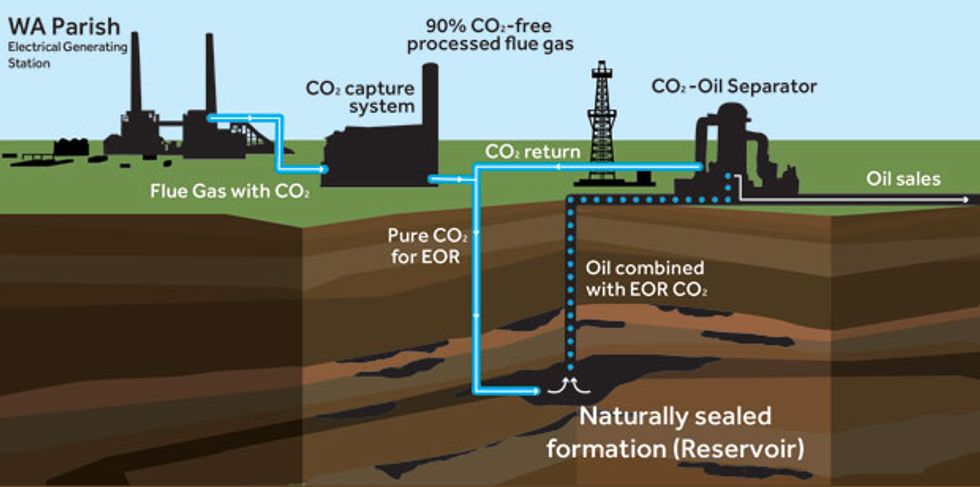

The system involved was tested at an Alabama facility earlier; it uses an “advanced amine-based CO2 capture system.” Basically, the CO2 reacts with an amine-based solvent, and the combination is then broken up using steam; the CO2 that is left over is compressed, and then sent via pipeline to the West Ranch oil field about 80 miles away. There, it will be used for enhanced oil recovery, which raises some questions about the actual environmental benefit involved here.

Proponents of this type of idea say that the oil that is extracted and burned is essentially carbon neutral, since CO2 was stored permanently (probably) underground in order to get it out. But as per the DOE’s press release, this particular project (and presumably others like it) will “be used to extract additional, hard-to-access oil from a previously depleted field.”

If we didn’t pipe captured CO2 over to the oil field, the economics of extraction might mean that whatever is left down there would stay there, forever. If we stored the captured CO2 without extracting oil, that means less CO2 in the air when all is said and done.

Of course, the economics of CCS are obviously extremely touchy so far, as the shelvings and scale-backs have illustrated. So having some incentive for fossil fuel companies to further develop these types of technology may be the only way that they get going at all.

At the Petra Nova project, 1.4 million metric tons of CO2 will be captured every year once it is up and running; it is estimated that the West Ranch oil field has about 60 million barrels of oil recoverable using enhanced extraction techniques, and production will be boosted from 500 barrels per day up to 15,000 per day, or more than 5 million per year. If we use the EPA’s figure of 0.43 metric tons of CO2 per barrel of crude oil, that means 2.35 million metric tons of CO2 per year, dwarfing the captured CO2 at the coal plant by almost a full million metric tons.

The math on CCS, clearly, isn’t quite where it needs to be.

Dave Levitan is the science writer for FactCheck.org, where he investigates the false and misleading claims about science that U.S. politicians occasionally make.