In the commercial world of batteries for electrical vehicles (EVs), lithium-iron-phosphate batteries are the popular approach among lithium-battery technologies because of their safety and durability.

This has already led to some disputes, developing in the last couple of years, over charge/discharge rates and intellectual property rights within the field.As if the commercial situation were not tense enough, it now appears there is a new player in the lithium-iron-phosphate battery universe. The new start up is called Wuhe, and it is located outside of Beijing.

Wuhe was founded by Yu-Guo Guo, a professor at the Institute of Chemistry at the Chinese Academy of Sciences (CAS), and is based on work he has published in journals such as Energy and Environmental Science.

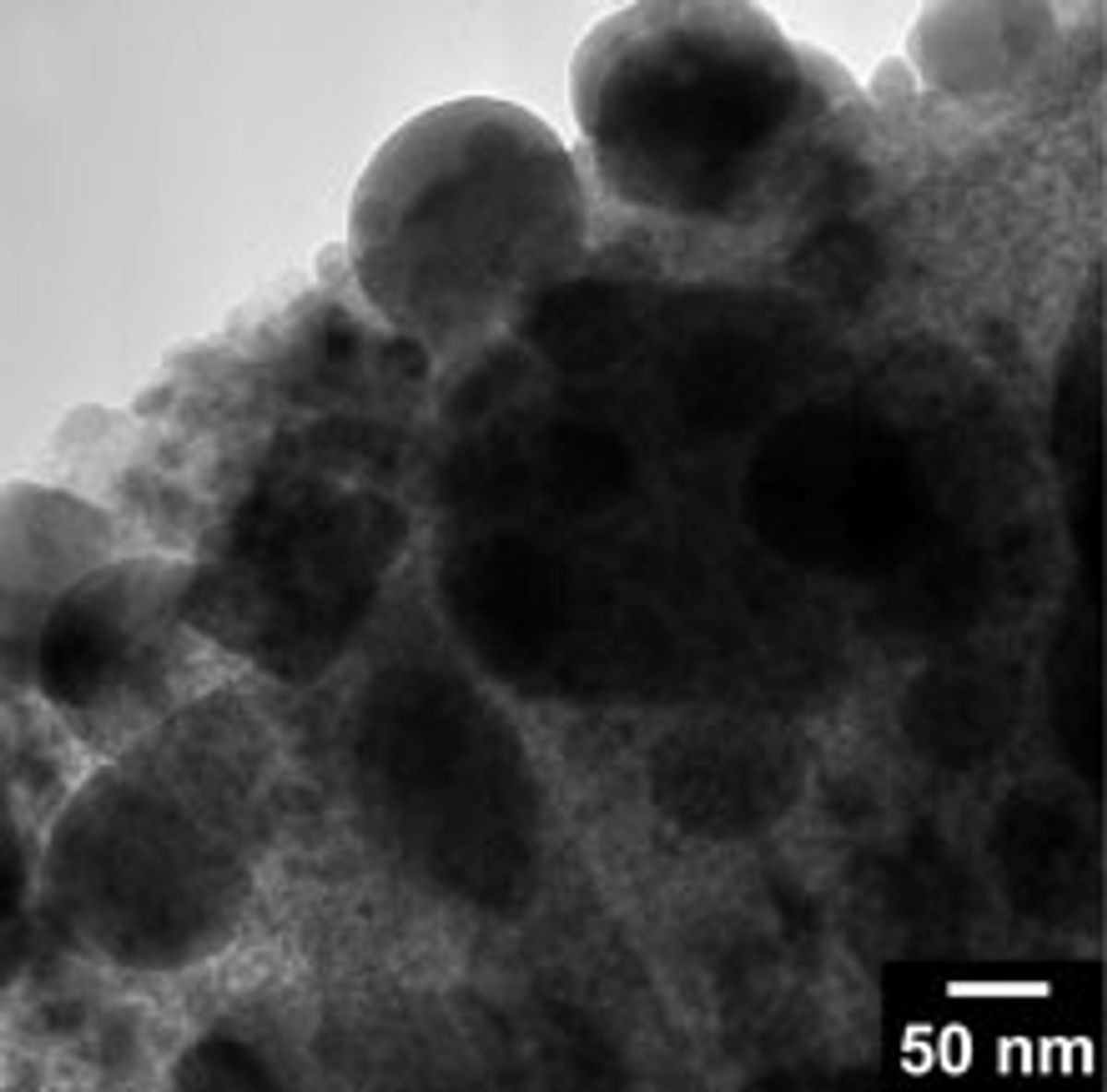

The reduction in production costs seems to come from the material's being easier to work with than the fine nanoscale powders of lithium-iron phosphate produced by companies such as A123 Systems. Instead Wuhe seems to use lithium-iron-phosphate nanoparticles embedded in larger particles of porous carbon, based on some of the other research published by Guo.

Guo claims that the production method costs only 10 to 20 percent more than bulk lithium-iron phosphate but produces twice as much power as the bulk material while making available twice as much energy in the lithium-iron phosphate, which results in an approximately doubled energy storage capacity.

It does seem odd that in the reporting of this, there is no mention of how Wuhe’s nanoparticles are easier to work with than the milled nanopowder, resulting in a 10 percent reduction in production costs. But I guess that will be something of which they will have to convince their buyers.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.