When it comes to talk of keeping Moore's Law on track, transistors seem to get all the attention. But the effort to boost the density of interconnect—the metal lines used to wire all those transistors together—is facing troubles of its own.

On Tuesday, Applied Materials, one of the leading manufacturers of tools for semiconductor fabs, announced they'd come up with a new process that could address a few of the big stumbling blocks.

One of those is a simple matter of geometry: as trenches used to make copper lines become narrower, it becomes harder to lay down the metal without creating voids. Another problem is degradation. The smaller dimensions and higher current densities that come with miniaturization speed up a process called electromigration, in which the current running down a line kicks copper atoms into the surrounding material, creating what could be circuit-killing gaps.

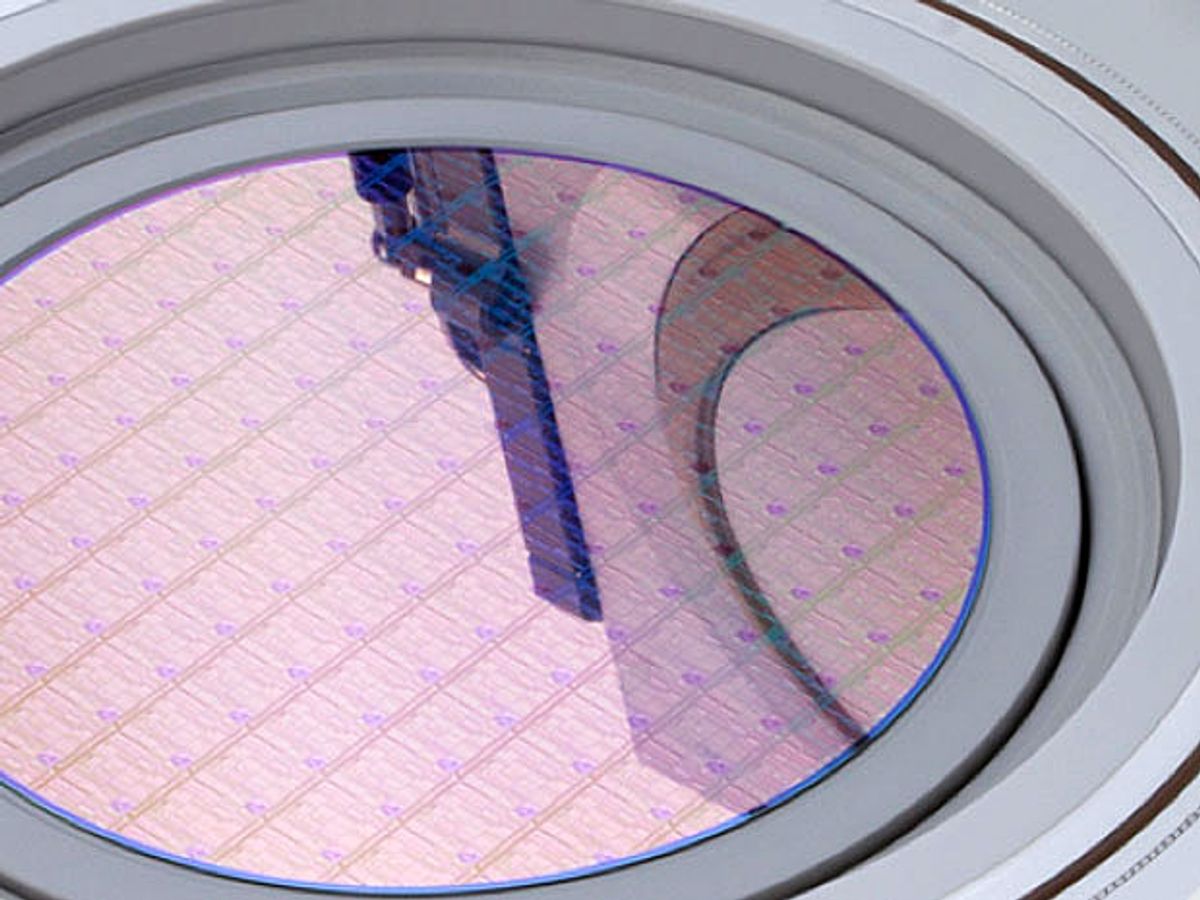

Image: Applied Materials

Applied hopes to address both of these problems by encapsulating copper lines in cobalt. A few-nanometers-thick layer of the material could first be used to line the inner surfaces of trenches that are to be filled with copper, to help the material spread out more evenly. When a copper line is completed, cobalt can then be used to cap the copper line to prevent electromigration.

The company has already prepared chemical vapor deposition chambers to deposit the cobalt and has shipped them to customers to test. This marks the first big change in the materials used to make interconnect in the last 15 years, says Kavita Shah, global product manager of Applied's Metals Deposition Group.

But for that to be the case, the technology must first be adopted for mass production, and it's not yet clear when it will be needed.

Applied's process builds off the existing approach to making interconnect, which calls for first adding a layer of tantalum or tantalum nitride to the trenches used to build copper lines. This metal layer acts as a barrier to prevent copper from diffusing its way out of the trenches.

Cobalt, along with other potential liner atoms such as ruthenium, might be good at getting copper to spread out, but it's not very effective at preventing diffusion, says Daniel Edelstein, an IBM Fellow at the IBM's Thomas J. Watson Research Center, in Yorktown Heights, N.Y. This means that, at least for the moment, the tantalum has to stay, and the cobalt layer will have to consume space in the trench that would otherwise have been used for copper. That may prove to be a hard trade for chipmakers make, Edelstein says: "We’re at the point where every nanometer of barrier thickness raises the line resistance by 20 percent."

Chipmakers will face another trade-off with the metal cap. A cobalt cap effectively shuts down copper migration, Edelstein says, but it adds extra risk to the manufacturing process, since a cap that spills over to a neighboring line can cause leakage or a short. Caps, albeit less effective ones, can currently be made in the same step as the copper lines, by filling trenches with a mix of copper and other metals such as aluminum and manganese. These other metals eventually self-segregate to form a cap at the top of the line.

Edelstein says that IBM, which collaborates with Applied on the cobalt technology, doesn't expect to need it for its 14-nanometer chips, the next generation down the line. But he adds that it will be important to have it when it is needed.

Should Applied's cobalt technology make it into mass production, it won't address one of the bigger elephants in the room: the increase in resistance and signal delays as lines get smaller, which can significantly impact power consumption and performance.

Little changes here and there, such as adding more metal layers with wider (and thus lower resistance) lines, could help ease the problem, Edelstein says, although it will add to the cost of chips.

But at least for now, we're stuck on the copper path. "No viable materials with resistivity below copper exist" that could take its place, the International Technology Roadmap for Semiconductors determined last year. Exotic materials such as carbon nanotubes and graphene could offer some relief "in the next decade," the report says. In the meantime, we'll have to keep fighting for each small improvement we can.

Rachel Courtland, an unabashed astronomy aficionado, is a former senior associate editor at Spectrum. She now works in the editorial department at Nature. At Spectrum, she wrote about a variety of engineering efforts, including the quest for energy-producing fusion at the National Ignition Facility and the hunt for dark matter using an ultraquiet radio receiver. In 2014, she received a Neal Award for her feature on shrinking transistors and how the semiconductor industry talks about the challenge.