What do you get when you mix a desert beetle, a pitcher plant, and a cactus? Pick the right parts and you get an extremely slippery surface with an uncanny capacity to condense and collect water, according to research reported today in the journal Nature.

The advance could be a big deal for the energy world because, when it comes to energy efficiency, condensation lies somewhere between a necessary evil and a major drag. Nuclear, coal, and thermal solar power plants, for example, require large heat exchangers to condense the steam exiting from their turbines so that they can raise a new round of hotter steam. For other devices, such as wind turbines and refrigerator coils, condensation is the first step towards energy-sapping ice formation.

Over the past decade rapid advances in biologically inspired materials have raised hopes for accelerating or guiding condensation via engineered surfaces, promising unprecedented control over water.

At least one bio-inspired surface treatment is in commercial use: The NeverWet surface protectant that paint manufacturer Rust-Oleum began selling in 2013, for example, contains nanoparticles that self-assemble to form a water-shedding surface roughness akin to that of a lotus leaf.

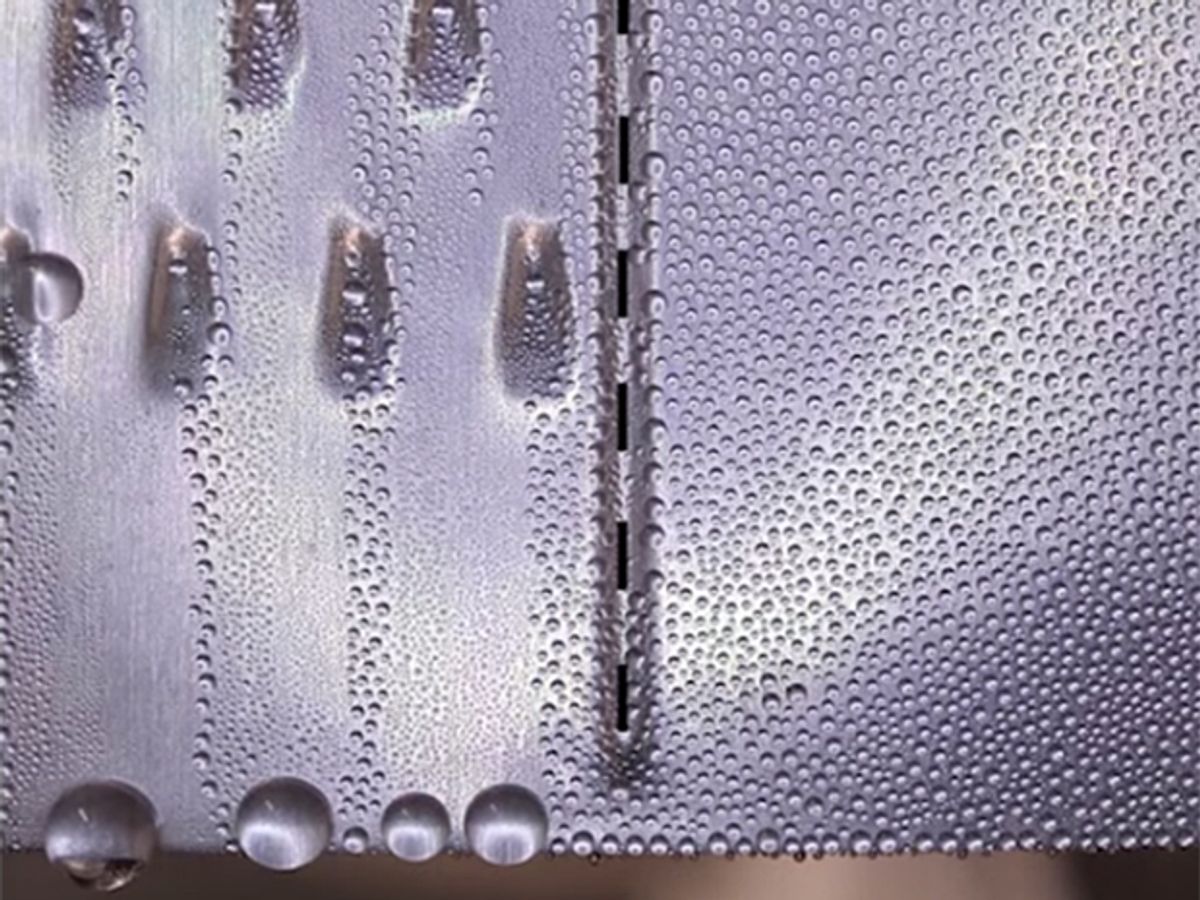

The research published today by Harvard University materials scientists pushes this biomimicry trend to the max in their triply-bio-inspired surface [at left in video above]. Its most novel element are asymmetric 0.9-millimeter-tall mounds, inspired by the condensation-promoting bumps adorning the backs of desert beetles such as Namibia’s Stenocara darkling beetles [photo].

Joanna Aizenberg, whose Harvard lab produced the work, says their paper provides the first theoretical framework explaining how convex bumps promote the condensation of water vapor into droplets—a trick that helps some desert beetles harvest moisture from fog.

Droplets formed on the Harvard team’s mounds glom together and roll off via a side ramp modelled after the water-droplet-guiding concavity of cactus spines. The final element are nano-pores across the entire surface infused with lubricant to create a slippery surface modelled after the trap of the carnivorous pitcher plant, in which prey literally hydroplane to their demise.

Harvard has already refined that final element—lubricant infused nano-porosity—into an impressive water-hustling technology in its own right. Their so-called SLIPS design is en route to commercialization via SLIPS Technologies, a spin-off launched in 2014 with US $3 million in venture funding and a joint development agreement with German chemicals giant BASF.

SLIPS Technologies chief technology officer Philseok Kim, a coauthor on today’s paper, says SLIPS-produced surface treatments and films are presently being tested on a skyscraper in New York City to document its ability to prevent ice and snow accumulation. Other applications are coming, including an anti-fouling coating for marine environments.

Harvard’s latest surface, however, is several times better at condensing water into droplets and hustling those droplets away than SLIPS alone [at right in the video above]. That could be of big value for heat exchange surfaces in power plant condensers, says Aizenberg, because droplets form an insulating barrier that slows further condensation: “You want to make sure they’re effectively removed from the surface as fast as possible.”

In fact, argues Aizenberg, the water condensing performance may be fast enough to enable a directly bio-inspired application: moisture harvesting systems for remote communities. Their surface may be able to condense moisture and collect it fast enough, even in arid environments where water droplets evaporate quickly.

Tak-Sing Wong, a materials scientist at Pennsylvania State University who is designing his own bio-inspired slippery-surfaces, says the Harvard work could double the efficiency of power plant heat exchangers. “Forming droplets that can shed off of the surface is very important because it takes heat away immediately. The amount of water collected will be proportional to the heat that’s taken away from the surface,” says Wong.

Another energy-related device in line to benefit are refrigerators, which periodically heat their coolant coils in a constant battle against frost buildup. Wong says bio-inspired coatings could ultimately reduce refrigerators’ electrical consumption by 30 percent or more.

Commercialization could come quick, he says, because these sophisticated designs need not be difficult to manufacture. Mature embossing and imprinting methods can produce millimeter-scale bumps in a wide range of metals and other materials, while the nanotexturing required for SLIPS can be etched into materials with acids or high-temperature steam. With the right application Wong bets that the first commercial uses will begin in as little as two to five years.

Peter Fairley has been tracking energy technologies and their environmental implications globally for over two decades, charting engineering and policy innovations that could slash dependence on fossil fuels and the political forces fighting them. He has been a Contributing Editor with IEEE Spectrum since 2003.