Roboticists have long been trying to build robot arms that are light, nimble, and safe to operate near people. Some designs rely on compliant actuators, artificial muscles, or sensors and software to keep the arms from smashing into things that they’re not supposed to. The challenge, however, is that most robot arms are stuffed full of electric motors and gears, and these are relatively big and heavy, adding to the size and weight of the arms.

Now engineers at Disney Research have come up with an ingenious way of making robot arms that are low mass but high speed. Instead of conventional motors, their arm uses what’s called a fluid transmission. It consists of tubes filled with air or water that connect antagonistic actuators. The result is a system that’s passively safe and compliant and lightweight and backdriveable and backlash free and... Well, it goes on. This thing is cool.

A fluid transmission is just a tube filled with a gas or liquid. If you push on the fluid in one side, that force is transmitted through the fluid to the other side of the tube. One of the advantages of a system like this is that you don’t have to place motors right next to a joint that you want to actuate: you can route the tubes through the arm and place the motors, controllers, and other bulky parts of the actuation system on the base or torso of your robot. This gives you an arm that’s low mass yet powerful.

This idea is not entirely new. Roboticists have been doing just that using traditional pneumatics and hydraulics as well as physical cables. But these approaches have limitations. With pneumatics and hydraulics, you can certainly get power and speed, but you often need to deal with leaks and friction and elaborate arrangements of pumps and valves and whatnot. With cables, the challenge is running many of them through tight spaces inside a robot; plus, the cables themselves stretch over time, and they’re usually not designed to be backdrivable. (Exceptions include the actuators in Aldebaran’s Romeo humanoid and the Barrett WAM, a popular arm used in research.)

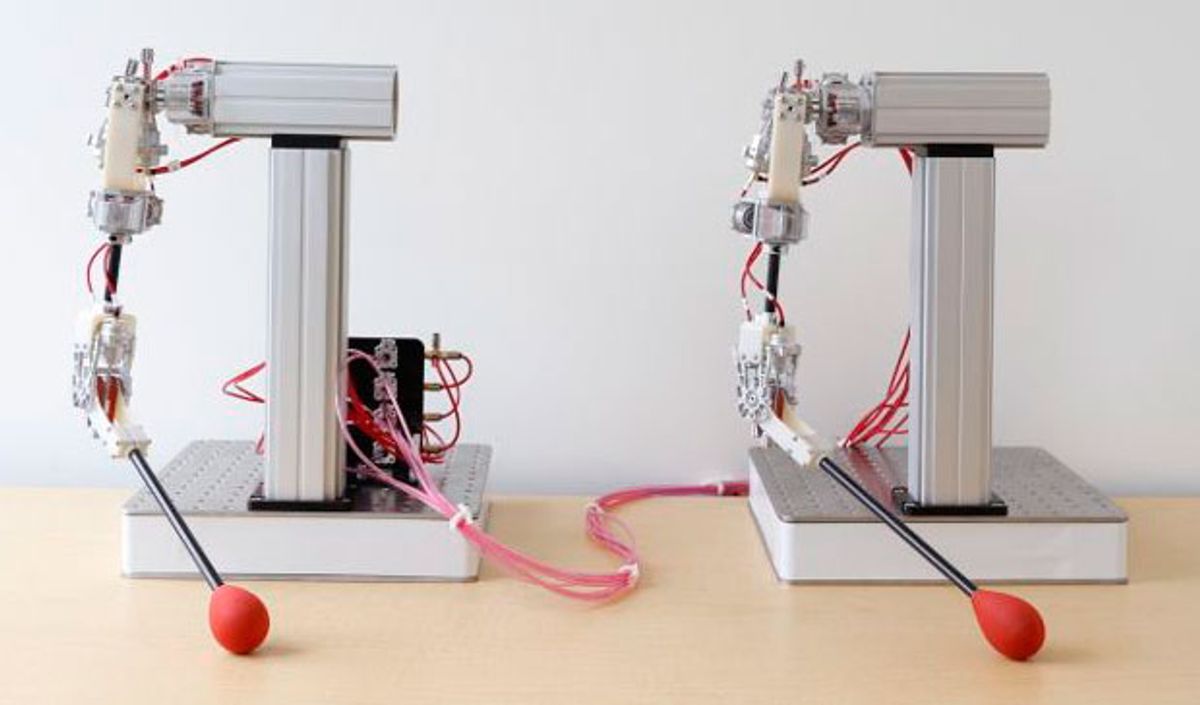

The Disney engineers wanted to avoid those problems. John P. Whitney and Tianyao Chen decided to try using a fluid transmission. They designed and built two robot arms that are connected by tubes pumped full of either air or water. As the video shows, if you move one of the arms using your hands, the other arm repeats those same movements. We expect that in the future the researchers will move from simple teleoperation to a setup that allows them to explore autonomous capabilities.

Their current system operates at 100 to 160 psi, which is achievable with a bicycle pump. Normally, the tubes would be attached to pistons at either end, which would lead to a huge amount of friction and sticking and render the whole system annoying. Instead, the secret to the performance of their fluid transmission is a system of preloaded, balanced rolling diaphragm cylinders that exhibit virtually no friction and are leak proof:

Here’s a diagram just to make sure things are clear:

With air inside the tubes, you get a passively compliant system, because the air can compress inside the tubes. If instead you use a noncompressible fluid (like water), the coupling becomes more rigid, up to the point where you can feel haptic feedback. In either case, the extreme low friction makes it possible for movements to be fast, precise, and delicate.

The first generation of their fluid actuator (built with off-the-shelf parts) was slightly better than a lightly geared brushless motor in terms of torque-per-weight (torque density). But the researchers were able to improve their design by incorporating components that are much lighter and diaphragms that work at a higher pressure.

They say the new version [picture below] has a torque density that is equal to or better than a highly geared servo motor, and much better in terms of power density because of its high speed. It can deliver 4.5 Nm of continuous torque, has a range-of-motion of 135 degrees, and weighs 120 grams.

As far as the Disney part of Disney research goes, it’s likely that a system like this will show up in next-generation animatronics that not only perform to an audience but also interact closely with people. In these cases, lifelike speed and precision are as important as safety.

“A Low-Friction Passive Fluid Transmission and Fluid-Tendon Soft Actuator,” by John P. Whitney, Matthew F. Glisson, Eric L. Brockmeyer, and Jessica K. Hodgins, from Disney Research and Carnegie Mellon University, was presented last month at IROS 2014 in Chicago.

[ Disney Research ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.