Differential scanning calorimetry (DSC) is one of the most used thermal analysis techniques in the industry. These calorimeters measure heat flows and temperatures associated with exothermic and endothermic transitions. In the DSC technique, the difference in the amount of heat required in order to increase or decrease the temperature of a sample and reference is measured as a function of temperature.

Typically, DSC is used for investigating, selecting, comparing and end-use performance of polymer materials or resins, as well as interaction of these base resins with additives like filler, pigments, dyes, catalysts and function chemical agents (stabilizers, oxidation inhibitors, plasticizers, etc.). It is also used in the analysis of foods, sugars, oils, active pharmaceutical ingredients (APIs), lubricants, metals, alloys, polymorphic materials (e.g., carbon) composites and other chemicals.

In order to thoroughly analyze modern materials such as metastable materials and nanomaterials, DSC instruments with ultra-high heating and cooling rate are required to capture the reactions, phases changes and physiochemical phenomena occurring. Faster heating rates can increase the DSC sensitivity and productivity, but the temperature resolution and accuracy can be reduced at high rate unless.

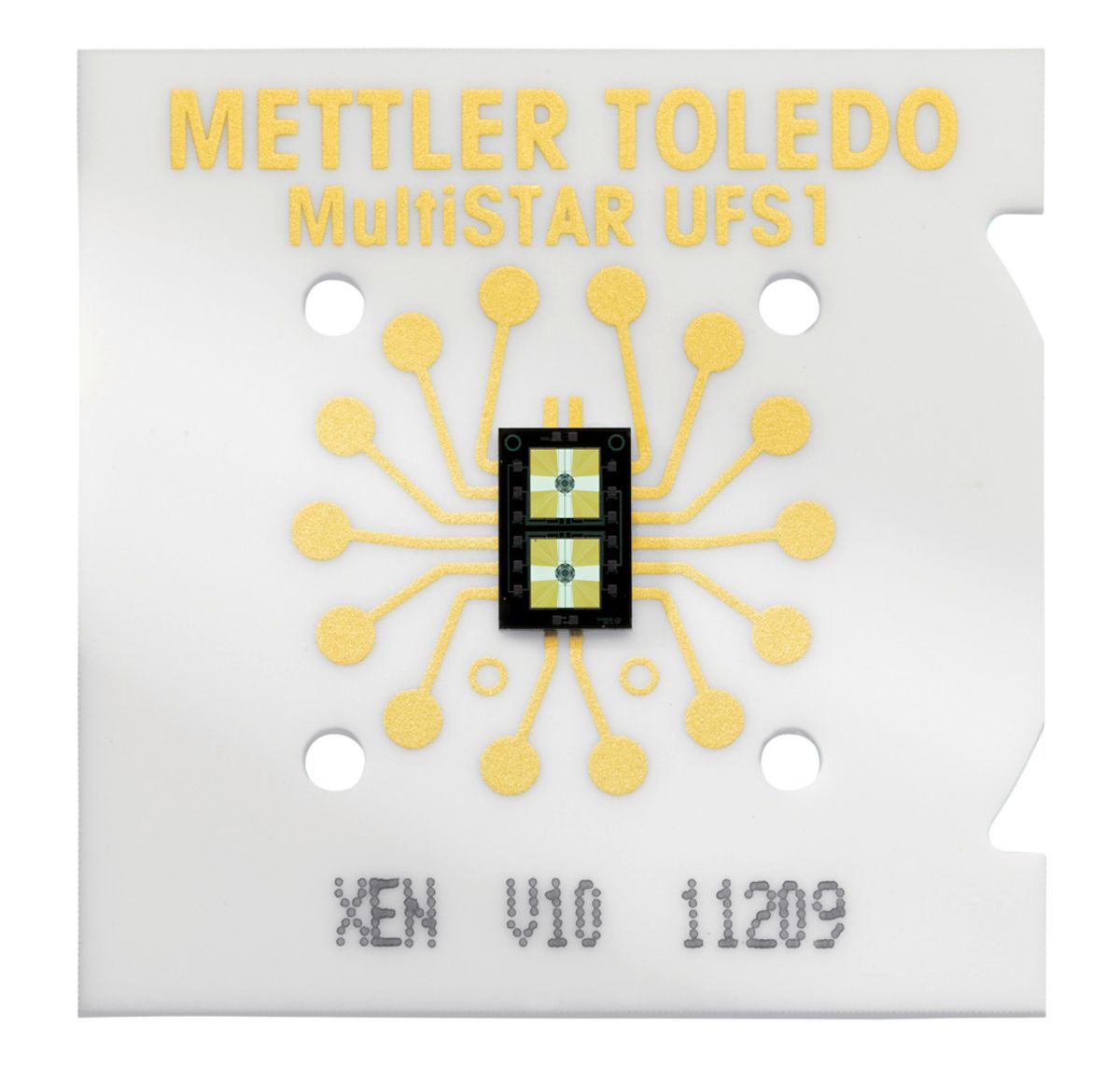

Mettler-Toledo supplies flash DSC units from can rapidly heat and cool samples while measuring the thermal response with high accuracy and sensitivity. Flash DSC is also an extremely useful too in simulating the heating and cooling conditions in modern materials and chemical processes such as the chilling and crystallization of polymer resins during injection molding. Certain DSC peaks corresponding to nucleation, crystallization, decomposition or other reactions can shift depending on the actual cooling or heating rate.

Applications for DSC include academic, industrial and government research facilities, and quality control and production operations. Heating and cooling rate process interactions and material properties that are routinely measured with ultra-fast DSC systems include glass transitions, "cold" crystallization, phase changes, melting, solidification, crystallization, product stability, curing, reaction kinetics, component reactions or interactions, decomposition, sample purity, nucleating agents, kinetics of structure formation, specific heat, aging, heat of mixing, phase separation, sample composition, and oxidative stability.

Mettler-Toledo put together an in-depth presentation discussing the basic principles of Flash DSC and presents some interesting applications, hosted by one of its Senior Scientists. If you’d like to learn more about the technique, you can register for free and get your hands on these materials.

As an added bonus, attendees of this IEEE Spectrum webinar have the opportunity to earn PDHs or Continuing Education Certificates! To request your certificate you will need to get a code. Once you have registered and viewed the webinar send a request for a webinar code. To request your certificate complete the form here.