Lithium-ion (Li-ion) batteries have proven themselves to be one of the most dependable energy storage technologies at our disposal. Unfortunately, they have a rather pronounced Achilles Heel: a non-aqueous electrolyte that is fairly combustible and as a result poses a significant fire hazard.

The stories of battery fires in Tesla cars, or the estimate from the Federal Aviation Administrationthat a fire in a Li-ion battery grounds a flight every 10 days, serve as testaments to what a serious issue this hazard has become.

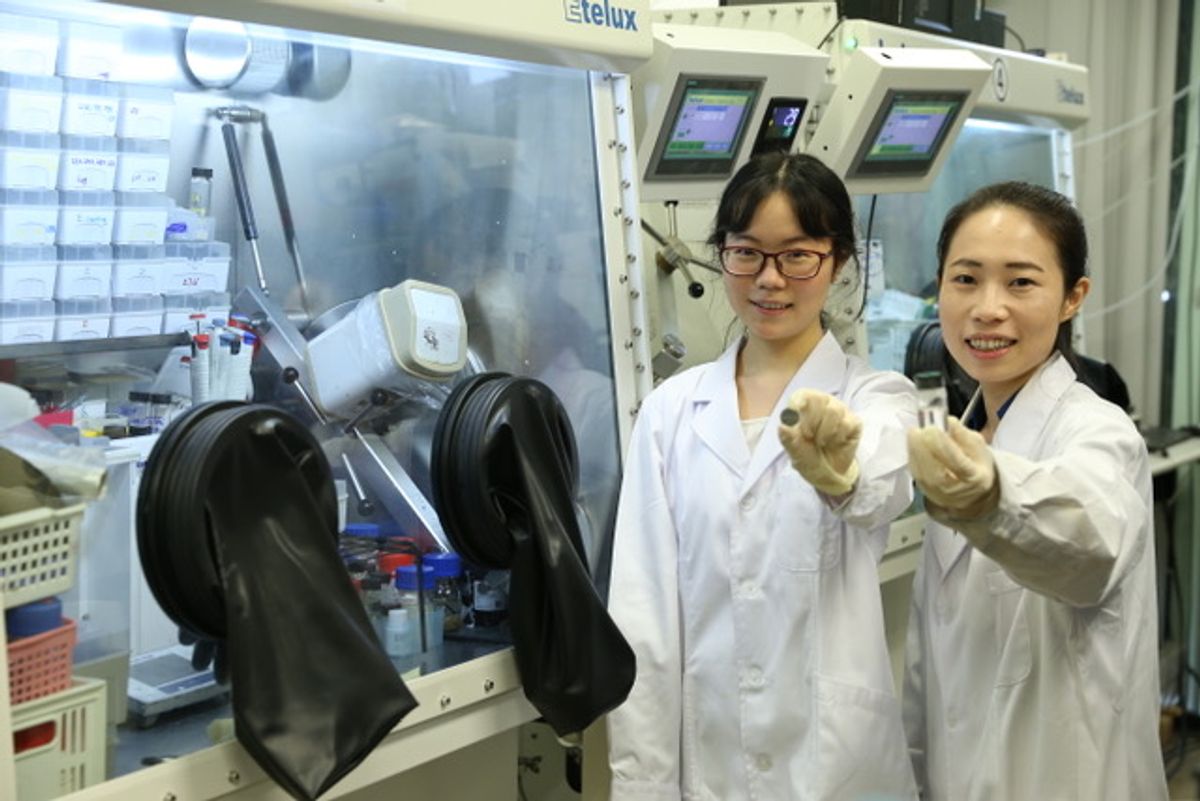

In a very big step towards solving this problem once and for all, researchers at The Chinese University of Hong Kong (CUHK) have developed a non-flammable, eco-friendly and low-cost aqueous electrolyte based on a skin cream ingredient that can still provide high energy density unlike previous aqueous-based electrolytes.

“If one wants to fully eliminate the fire issue in batteries, using a water-based electrolyte is the most effective strategy," explained Prof. Yi-Chun Lu, who led the research at CUHK. “When we developed our project, our aim was to develop a water-based electrolyte that delivered high voltage while maintaining a low cost and remained environmentally friendly."

In the video below, you can see how the aqueous electrolyte is produced and see how non-flammable it is compared to electrolytes currently used in Li-ion batteries.

Non-aqueous electrolytes are ubiquitous in the Li-ion batteries of today for one simple reason: they deliver high energy density (100-400 watt-hours per kilogram (Wh/Kg)). As alternatives to non-aqueous electrolytes, researchers have begun to use highly concentrated salts in aqueous electrolytes to try and reach the energy density of non-aqueous electrolytes. However, these high-salt aqueous electrolytes create a battery chemistry that is highly toxic as well as leading to a relatively expensive battery to produce.

“While aqueous electrolytes have been used for many years, existing water-based electrolytes sacrifice voltage window or increase cost and toxicity in exchange for safety," said Yi-Chun Lu.

In looking for a solution to this issue, Yi-Chun Lu and her team at CUHK turned to nature to leverage something known as “molecular crowding" for an inexpensive and eco-friendly alternative. Molecular crowding is a phenomenon that occurs inside living cells in which molecular crowding agents significantly suppress water activity by changing the hydrogen-bonding structure inside the cells.

In their research described in the journal Nature Materials, Yi-Chun Lu and her team employed a polymer often used in skin creams to serve as the crowding agent. This crowding agent decreases the water activity and thereby enables a wide electrolyte voltage window with low salt concentrations. (An electrolyte voltage window is the voltage gap between the positive and negative side of the battery, and, in this case, is 3.2V).

While this electrolyte can be used with any kind of electrode materials that are within its electrolyte voltage window, it cannot currently work with electrode materials that fall outside its voltage window.

This limitation on the choice of electrode materials meant that the prototype was only able to achieve 75-110 Wh/kg, which remains still below the energy density of typical Li-ion batteries that range between 100-400 Wh/kg.

This limitation can be overcome, according to Yi-Chun Lu, by increasing the voltage window to enable electrodes that sit at an even lower potential such as lithium metal.

“We have demonstrated this possibility by using gel coating in our new electrolyte to achieve a 4.0V battery using a lithium anode," said Yi-Chun Lu. “With proper improvements of the electrode and electrolyte, the energy density possible for this class of electrolyte should be the same as typical non-aqueous electrolyte, say between 200 to 260 Wh/Kg."

Testing the compatibility of the electrolyte with more electrode materials is the focus of ongoing research and one of the engineering challenges in bridging the technology from a lab prototype to commercial production. The researchers will also be increasing the number of times they have charged and discharged their batteries (known as cycles) from 300 cycles to 500 while they improve the electrolyte with a higher voltage window.

In terms of commercializing the technology, the CUHK team has not yet collaborated with commercial battery manufacturers in the development of their prototype, but they are now seeking industrial partners. In the meantime, they have filed for a US patent on the electrolyte.

While the research was not done in collaboration with an industrial partner, it was most certainly guided by commercial considerations.

“Low cost, high voltage and high safety are our major strengths," said Yi-Chun Lu. “We anticipate good markets for this technology in any application that requires ultra-safe batteries."

Safety in larger battery systems is a more pressing issue than smaller portable electronics, according to Yi-Chun Lu.

Yi-Chun Lu added: “I think this technology will be very attractive for applications like large-scale grid storage (interfacing with solar or wind farm) and electric vehicles (with further development in energy density)."

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.