10 Tech Companies for the Next 10 Years

From undersea robots to power electronics, technology’s future belongs to the bold

In 1964, the year IEEE Spectrum published its first issue, Texas Instruments received a patent on the integrated circuit, RCA developed the videotape cartridge, Sharp introduced the all-transistor electronic calculator, Digital Equipment Corp. shipped the PDP-8 minicomputer, and IBM coined the phrase “word processing.” All those companies were pretty big, even then—it isn’t easy to find a 1964 start-up that was betting its all on a technology that has since paid off.

Four decades later, venture capital has worked a sea change in the way industrial innovations are made. If in the days of Hewlett and Packard the garage start-up was the exception, today it is the rule. We have therefore tried to divine the future from a collection of today’s most daring tech start-ups. We narrowed the field by considering technological innovations in conjunction with the people who have bet on them; people, unlike new ideas, have track records that can be vetted. The board of editors of Spectrumdid the vetting, aided by many IEEE fellows.

Another constraint was to allow only one company per category. That way, software and telecom would not overwhelm everything else, and the predictions would not boil down to one or two ideas which, if proved wrong, future list makers would find laughable. Of course, the categories were shaped in part by the available candidates for the list, like the bull’s-eyes of a marksman who shoots first and draws the targets afterward.

Displays: Microvision Inc.

Bothell, Wash.

Photo: Rodney Oman

Display devices have a few weak points—they’re bulky, hot, conspicuous, and power-hungry. Ugly, too. Microvision proposes to solve all these problems at a stroke by using solid-state lasers and LEDs to paint fine-grained pictures directly onto your retina. As John R. Lewis, a research fellow at the company, wrote in these pages (“In the Eye of the Beholder,” Spectrum, May 2004), “Short of tapping into the optic nerve, there is no more efficient way to get an image into your brain.”

It’s a bit like the head-up display, which floats meter readings and other aeronautical data somewhere in the middle distance in front of a pilot’s face. Even better, though, Microvision’s system can superimpose graphical information on the real world, much as Walt Disney Co. animators had Mickey Mouse shake hands with conductor Leopold Stokowski in Fantasia in 1940. A surgeon (or a combat medic trying to act as one) might use superimposed anatomical information to guide a scalpel; an auto mechanic might use data positioned in this way to guide a wrench. The latter application is already in use, in Microvision’s Nomad Expert Technician System.

The company uses microelectromechanical system (MEMS) devices to scan the beams back and forth and, where appropriate, to mix different colors to produce white light. Because the beam sweeps over the retina instead of dotting it, lines need not be serrated and images need not be grainy. Bright as the picture will seem to the naked eye, it will consume barely a microwatt, potentially saving hugely on battery power. And, by sending light only where it’s needed, the system can keep nosy neighbors in adjacent airline seats from snooping on your work (or play). With a sufficiently inconspicuous eyepiece, one might even feign attention to a speech or lecture while, in fact, watching television.

Offshore Technology: Cybernetix

Marseille, France

Illustration: Bryan Christie

No harsher environment for robots exists than the bottom of the sea—and no more alluring one, given recent advances in oil-discovery technology. Cybernetix is finally building functional submarines that qualify as robots, able to steer themselves to a target, recognize it, and manipulate it.

The company’s several kinds of autonomous underwater vehicles (AUVs) will all draw power from sources designed into undersea drilling rigs. So, while these vehicles cannot yet be used to build rigs, they should prove a cost-saving convenience for rig maintenance and repair companies. Cybernetix performed trials recently off the coast of Marseille, where the sea floor slopes steeply to a kilometer underwater, unlike the floor of the Atlantic, which slopes gently. Under these trying conditions, the prototype robosub proved its powers by opening and closing the simulated valves of a mocked-up rig with the claws of its hydraulically powered arms.

Today, the only way to do the job is with a remotely piloted vehicle, which requires two surface vessels—one, a specialized craft capable of paying out thousands of meters of cable to supply power and upload data, and the other, a spotter ship to help put everything in the right position. The AUV, on the other hand, needs just a single, ordinary surface supply ship. And while a remotely piloted vehicle costs US $80 000 a day to operate, the AUV would cost only $10 000 a day, according to Brian Morr, a British consulting engineer who works closely with Cybernetix. Additional economies are expected when the assurance of round-the-clock robotic repair makes it possible to build undersea equipment to less exacting standards.

Demand for such tools has arisen only in the past 10 years or so, as dramatic improvements in deep-sea prospecting have led oil companies to start drilling in the deep waters of the Gulf of Mexico. These companies are now showing interest in potential fields off the coasts of Norway and Africa. Whether or not these prospectors make money, Cybernetix stands to do well selling them the modern-day pickaxes they need.

Lighting: Lumileds Lighting LLC

San Jose, Calif.

Bridge Over The River Clyde: Light-emitting diodes dramatically define three bridges over Glasgow’s Clyde River. The 58-watt cool white LEDs emphasize the bridges’ structure and create a blue reflection in the archways above the water.Photo: LumiLEDS

Cartoonists may soon have to give up that quintessentially Edisonian symbol of a new idea, the light bulb. Now comes the time of an even newer one, the light-emitting diode (LED), only recently strong enough to begin competing with the light bulb in a variety of applications in all the colors of the rainbow, plus white light.

Lumileds, a joint venture between Philips Lighting BV and Agilent Technologies Inc.—which inherited the optoelectronic division of Hewlett-Packard Co.—holds a strong hand in the long-life side of the business. Its Luxeon line provides 70 percent of peak power after 50 000 hours of use, says Steve Landau, the company’s marketing communications manager. (For comparison, an ordinary incandescent light bulb typically lasts just 1000 hours or so.) Already the product figures in both interior and exterior architectural designs requiring that colored lamps be strewn in hard-to-service areas—underneath a bridge, say, or along the edge of a skyscraper.

Lumileds specializes in high-power LEDs, such as those that power the flash in the recently released Sendo X cellphone’s camera. The advantages are clear: LEDs fit into very small spaces such as the ones available in these phones. Yet even for purposes that incandescent bulbs can obviously serve, such as car lights, compactness can be valuable. Small assemblies make engineering easier, especially when the LED’s long life makes it acceptable to seal the assembly permanently. Toyota’s Estima car, in Japan, powers its brake light with just one Luxeon LED (in red, of course, which happens to be the brightest available color). Audi AG this year included five of Lumileds’ white LEDs in the assembly for a daytime running light in the 12-cylinder Audi A8.

Further gains are inevitable, if one believes the obscure engineering dictum known as Haitz’s Law, which states that the flux of light from LEDs will double every 24 to 30 months, as it has for the past 30 years.

Communications: Meshnetworks Inc.

Maitland, Fla.

Wi-Fi In The Sky: Data hops from point to point across a grid of access points, including both wireless and fixed nodes (shown here).Photo: Ed McDonald

MeshNetworks’ “meshing” innovation handles high-bandwidth data transmission for mobile applications, a technical challenge in part because moving nodes tend to lose contact with their peers. By relaying data mainly through nearby devices in a process it calls Multi-Hopping, the company can save on infrastructure, speed up deployment, and resist both system overload and deliberate sabotage. For these reasons, the firm’s initial markets are in the military and emergency-response services.

How it works: users of the company’s products form networks with one another on the fly, with a little help from a bare-bones network of wireless routers. Scattered access points to the wired world complete the picture.

"The thing about meshing is that you regenerate at every hop, and though there is some lag, the tradeoff buys you increased throughput," says Peter Stanforth, MeshNetworks’ CTO. He notes that although a 100 percent lag at a hopping point will halve the effective bit rate, it may still be well worth the loss if a transmitter can thereby exploit a data-hurling but short-range standard, such as IEEE 802.11, popularly known as Wi-Fi. "Every device makes the cost-benefit calculation for itself to determine the best route to take," he says.

The technology comes out of military research done by ITT Industries, White Plains, N.Y., funded by the U.S. Defense Advanced Research Projects Agency. MeshNetworks has built upon that intellectual property by working out routing algorithms, battery lifetimes, and other engineering constraints for terminals, and ways for transmitters to fix their locations without reference to GPS, which may not work in urban canyons or inside burning buildings.

The police and utilities departments of Medford, Ore., are deploying a MeshNetworks system. Another potential market is the intelligent highway, which would allow moving vehicles to share data in some scenarios, such as increasing traffic flow. One step in that direction is the public-transport service of Portsmouth, England, which is providing 45 kiosks that allow pedestrians to track the progress of moving buses.

Cryptography: Magiq Technologies Inc.

New York City

Illustration: Bryan Christie

Not long ago, you could sleep soundly knowing that public-key encryption was keeping your most sensitive data safe. But faster hardware and ever-sharper algorithms have since shown that the method sometimes has feet of clay, and interest has focused on a theoretically unbreakable alternative: quantum cryptography.

The idea has been in the public domain for 20 years, but MagiQ has amassed a wealth of intellectual property in adapting it to commercial use. "We think the very near-term market is in the hundreds of millions of dollars globally," says Robert Gelfond, founder and CEO of the company.

Here’s how it works: the sender uses two random-number generators: one to come up with a bit of information—say, “0”—and the other to choose in which of two ways to polarize the bit on a photon. Next, he sends the bit to the receiver, who guesses the polarization state publicly. The sender then announces, again publicly, whether the guess was right.

After piling up a sufficiently long string of bits this way, both the sender and the receiver will be in possession of the same key, the basis for a "symmetric" coding system (unlike public-key encryption, which uses two keys). Even a symmetric key can be cracked, in principle, but if you want absolute security, you just generate a key as long as your message and never use it again. Such codes, called one-time pads, are theoretically unbreakable.

Why go to market only now, two decades after the method was conceived? "Now we have true single-photon sources and better single-photon detectors," says Gelfond. "There’s also been a tremendous decrease in the cost of many optical components—lasers that cost $15 000 three or four years ago now go for $500. To build this device four or five years ago would have cost a million; we’re selling systems for $60 000."

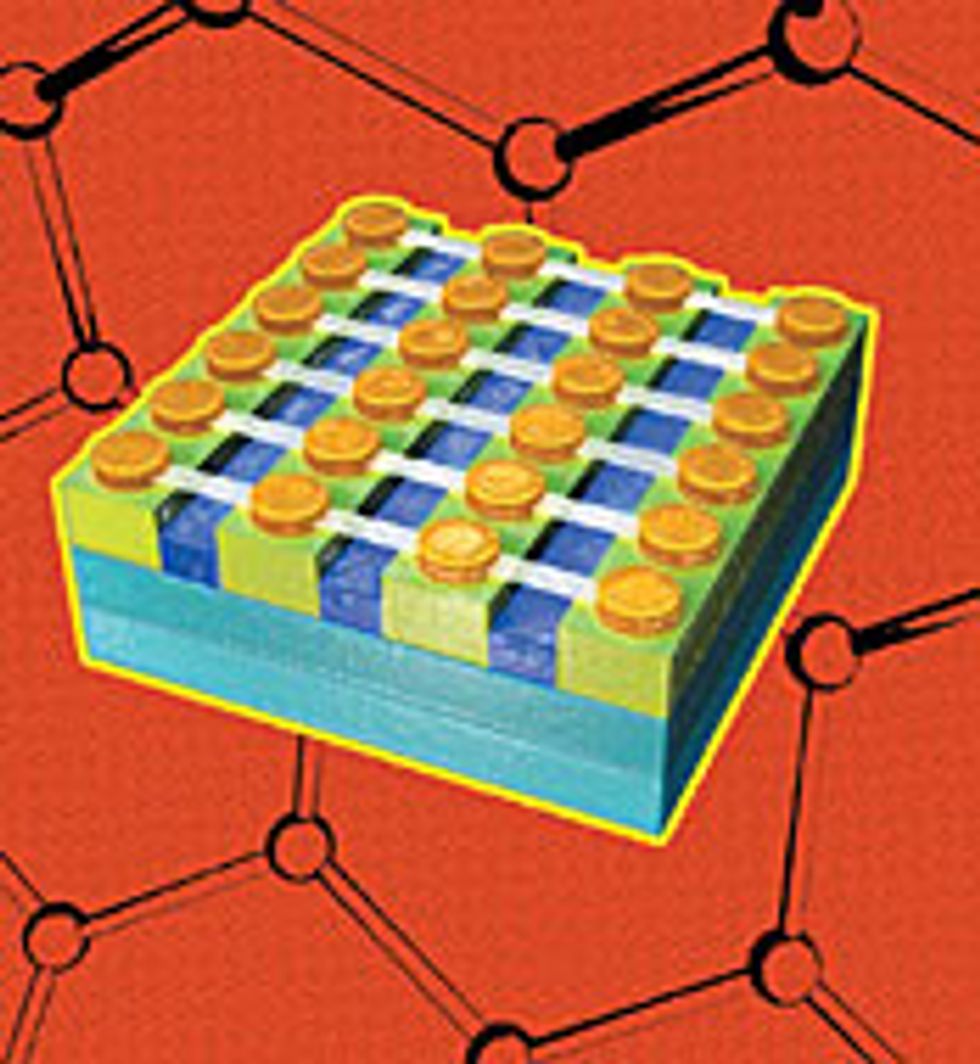

Nanotechnology: Nantero Inc.

Woburn, Mass.

Totally Tubular: Carbon nanotube ribbons link interconnects across electrodes. Flexing tubes touch the electrode to complete a circuit.Illustration: Bryan Christie

The new science of nanotechnology offers a tantalizing promise: the ability to build circuit elements from individual molecules. Only thus can the ever-threatened, never-yet-reached demise of Moore’s Law be deferred. Yet despite the ingenuity of the many schemes advanced, the proponents of molecular electronics could never see their way to a mass-producible product, until now. Nantero and its partner, LSI Logic Corp., Milpitas, Calif., recently announced that they have incorporated their technology—which relies on carbon nanotubes related to the famous buckminsterfullerene molecule—into a production line. Result: nanomemory chips that in principle should combine the best qualities of flash memory, DRAM, and SRAM technologies.

"We are using a hybrid approach, taking an existing silicon technology and adding a couple of steps to get the nanotubes in place," says Greg Schmergel, cofounder and CEO of Nantero. "We will never ask somebody to build a fab around us. We will instead make it in existing fabs, as LSI is doing." LSI is doing the work in a state-of-the-art CMOS fab in Gresham, Ore.

In Nantero’s microchips, ultrasmall mechanical switches deform under the influence of an electric field to complete a circuit. Because the two states—on or off, one or zero—are locally stable, the switch stays switched, with no need to refresh. It is therefore nonvolatile, like flash, as well as dense, like DRAM, and fast, like SRAM.

Exactly how the production line works is a trade secret. Schmergel will say only that workers etch wafers, then lay on a solution of nanotubes so that it somehow forms a film one tube thick. Next they etch away superfluous tubes, leaving those lying in the prepared places stretching between points, creating room in which they can flex in an electric field, until their "bellies" touch an electrode, completing a circuit. To make sure it happens, they use up to a dozen tubes to encode each bit of memory.

Being nonvolatile, such devices could power "instant-on" computers, which do not need to boot up. What is more, their mechanical elements are inherently resistant to radiation, a matter of importance for military and interplanetary applications. These little tubes could turn out to be very big indeed.

Computers: Picsel Technologies Ltd.

Glasgow, Scotland

View Finder: The Picsel Viewer lets users pan, zoom, and manipulate common file types without converting them to fit a PDA’s small display.Photo: Picsel Technologies Ltd.

Each new vehicle for computation starts off looking like a toy to the champions of the one just before it—minicomputers to the mainframers, PCs to the mini guys, laptops to those who program PCs. During this "just a toy" phase, application software seems clunky, and the first company to bring it out in a pleasing form stands to win the jackpot. Picsel hopes to do this for PDAs and other mobile platforms by fitting Web content onto itty-bitty displays.

Imran Khand, CEO and founder of Picsel, says his company’s software solves the problem well enough to display information on set-top boxes, PDAs, and cellphones as clearly as it now appears on laptop monitors. "You can see graphics, zoom in or out, pan about, just as you can push one piece of paper away on your desk and pull another one closer to read it," he says.

The software’s coded "footprint" can fit comfortably inside the available shoe, occupying just 0.5 to 1.5 megabytes. New models of the Sony Clié use Picsel Viewers to display files in common applications such as Microsoft Word. A browser application will read HTML, flash, and other Web site gimcracks. You can download skins for fashionable icons—the pictures associated with the movie Spider-Man, for instance—to make your cellphone into a moving advertisement; the same goes for phone tones.

Khand says that he found a lot of his company’s talent in Russia and China, where constraints of space and computing power had trained engineers to find elegant solutions. Picsel employed 60 people two years ago and has doubled that number since then. "We are being pursued by investment bankers, because we survived the downturn in technology," he adds.

Semiconductors: Crossbow Technology Inc.

San Jose, Calif.

Illustration: Bryan Christie

Walls may well have ears, at least in James Bond novels, but until recently it cost a lot of money to put those ears in place and even more to extract data from them. Crossbow means to change all that with its sensor-packed, self-contained, wireless beacons, called "motes." Because they connect with one another to form ad hoc networks, motes can track things that might otherwise be missed.

At Eglin Air Force Base in Florida, Crossbow is building perhaps the biggest ad hoc network ever. Some 10 000 motes, each a 10-inch cone containing a hand-size circuit board and four AA batteries, are placed at 30-meter intervals, with 300 Stargate single-board gateway computers (from Intel Corp.) positioned along the periphery as relays to the Internet. The information culled by the network is then analyzed in various topologies optimized to different purposes—from detecting intruders and determining whether they bear firearms to differentiating plain automobiles from armored vehicles. "The end result will be what we like to call an explosiveless land mine," says Samuel Godwin, Crossbow’s vice president for sales. "Rather than blow you up, it calls something else to blow you up or come and apprehend you."

The network of motes uses Tiny OS, a concisely coded operating system devised at the University of California, Berkeley.

Motes are custom made to fit specific applications—by miniaturizing the assembly, for instance, a strategy that involves sacrificing battery power in order to make the motes inconspicuous. The smallest version now available is about the size of a stack of three quarters (24 millimeters across and 5.25 mm tall). When produced in quantity, Godwin says, the motes will vary in cost from perhaps US $90 to $150 apiece, depending on capacity. The next goal is to cut the price and improve the motes’ powers of self-orientation to the point that they can be dumped out of airplanes to seed a wide area—an application full of military potential.

In commercial applications to date, the sensors have been used to monitor microclimatic variations in tree nurseries for the forestry company Weyerhaeuser Co., track engine vibrations on ships at sea, and detect long-term water seepage into window-seal assemblies. As the technology matures, expect to have the motes in all parts of your automobile.

Biomedical: MicroChips Inc.

Bedford, Mass.

Illustration: Bryan Christie

For a lot of medical therapies, success or failure turns as much on the mode of delivery of a drug as on the efficacy of the drug itself. Until now, delivery options have been limited to time-release capsules, which work only for short periods, to orally administered drugs, and to medicines that need not adjust to the changing needs of a patient’s body. MicroChips was founded in 1999 to fashion more dynamic drug-delivery devices, using the techniques of photolithographic manufacturing.

The company provides implantable devices that contain small, sealed cavities whose contents can be protected from the body until they are needed. Then MEMS-built devices expose the cavities, releasing the medication into the body.

One system the company is investigating would grasp the Holy Grail of intelligent drug-delivery systems: diabetes therapy. Currently, diabetic patients must inject just the right dose of insulin to control their blood-sugar levels, which they determine by pricking a finger four or more times a day. Attempts to monitor glucose continuously, with implanted sensors, have so far been unsatisfying, in part because enzymes used to sense glucose are used up or destroyed by the body’s immune system. “We realized that you could make a long-term implant not by making the sensor better but by using many of them,” says John T. Santini Jr., the company’s president and chief scientific officer.

He says MicroChips is working on chips the size of a pocket watch that could be placed under the skin. Automated controls would expose a cavity filled with sensor enzymes for a few days, or until the cavity fails, then unveil a new cavity to take its place. Wireless antennas would meanwhile download health data, as needed, from the patient’s responding body. In this fashion, a single implant might be able to cover a patient’s needs for months.

The chips could use the same cavity-revealing technique to release drugs. Insulin isn’t actually a candidate for this application because the necessary payload is too big, but other ailments requiring precisely calibrated drug delivery are under investigation, including osteoporosis and perhaps congestive heart failure—markets worth more than US $1 billion apiece.

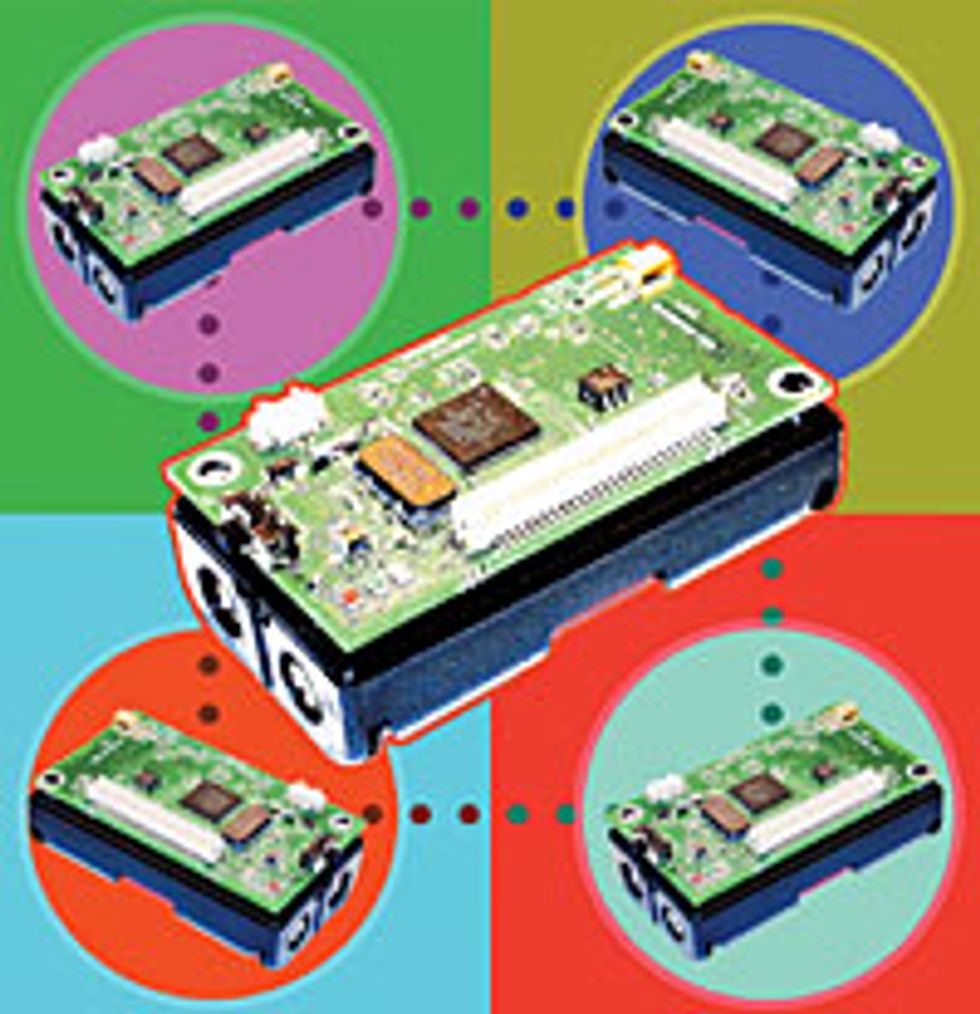

Power Electronics: Semikron International

Nuremberg, Germany

Get the Lead Out: Lead-free products like this rectifier help Semikron compete in European markets.Photo: Semikron International

Power electronics, virtually the only kind there was back in the days of Thomas Edison and Werner Siemens, may seem old hat. But the dexterity with which circuitry can master beefy currents matters greatly in technologies that involve variable energy flows, as many emerging technologies do, including those being used in electric and hybrid vehicles and wind turbines. Semikron, a 53-year-old company that is family owned and little known outside of Germany, its home country, nonetheless bears watching on account of its dominance in key world markets. The company leads Europe in power modules, with a third of the continent’s business; it holds even higher shares of the market for thyristors.

Gerlinde Stark, the company’s director of communications, attributes Semikron’s success in the variegated European market to its high commitment to R and D and its reliance on 53 full-fledged subsidiaries. "We have them even in smaller markets, such as Turkey, Croatia, and Denmark, and they are run by native speakers who really know the country," she says. Competitors, Stark says, often rely on distributors or dealers, which do not normally provide much technical support.

Semikron has a wide range of products, starting as low as 20 amperes but generally running around 100 A. Some handle megawatts—for instance, the 5-MW systems designed for windmills, which blend transistors, dc-link capacitors, cooling systems, and drivers. Even more promising are systems meant for electric vehicles, which include everything from forklifts to futuristic fuel-cell-based concept cars. Recently, General Motors Corp. named the Semikron Advanced Integration power electronics system for fuel-cell cars the best available. The system is smaller and more reliable than competing products and generates a quarter more power at 40 percent lower cost.

About the Author

Philip E. Ross (M) has written about technology for Scientific American, Forbes, and Red Herring. He previously worked the automotive beat in the Detroit bureau of The New York Times.

Photo: Rodney Oman

Photo: Rodney Oman Illustration: Bryan Christie

Illustration: Bryan Christie Bridge Over The River Clyde: Light-emitting diodes dramatically define three bridges over Glasgow’s Clyde River. The 58-watt cool white LEDs emphasize the bridges’ structure and create a blue reflection in the archways above the water.Photo: LumiLEDS

Bridge Over The River Clyde: Light-emitting diodes dramatically define three bridges over Glasgow’s Clyde River. The 58-watt cool white LEDs emphasize the bridges’ structure and create a blue reflection in the archways above the water.Photo: LumiLEDS Wi-Fi In The Sky: Data hops from point to point across a grid of access points, including both wireless and fixed nodes (shown here).Photo: Ed McDonald

Wi-Fi In The Sky: Data hops from point to point across a grid of access points, including both wireless and fixed nodes (shown here).Photo: Ed McDonald Illustration: Bryan Christie

Illustration: Bryan Christie Totally Tubular: Carbon nanotube ribbons link interconnects across electrodes. Flexing tubes touch the electrode to complete a circuit.Illustration: Bryan Christie

Totally Tubular: Carbon nanotube ribbons link interconnects across electrodes. Flexing tubes touch the electrode to complete a circuit.Illustration: Bryan Christie View Finder: The Picsel Viewer lets users pan, zoom, and manipulate common file types without converting them to fit a PDA’s small display.Photo: Picsel Technologies Ltd.

View Finder: The Picsel Viewer lets users pan, zoom, and manipulate common file types without converting them to fit a PDA’s small display.Photo: Picsel Technologies Ltd. Illustration: Bryan Christie

Illustration: Bryan Christie Illustration: Bryan Christie

Illustration: Bryan Christie Get the Lead Out: Lead-free products like this rectifier help Semikron compete in European markets.Photo: Semikron International

Get the Lead Out: Lead-free products like this rectifier help Semikron compete in European markets.Photo: Semikron International