Every year, ARPA-E (the government's Advanced Research Projects Agency-Energy) holds a big conference/partyin Washington, D.C., that includes an expo hall full of all of the latest, most exciting government-funded technology innovations in the energy sector. No, we're not being sarcastic. Last year, we focused on ARPA-E's push towards personal thermal regulation. The big idea: that heating an entire building is incredibly wasteful, when you could potentially save massive amounts of energy by heating each human inside of that building (or a small area around them) instead. We're happy to report that both RoCo and SRI's foot coolers have been significantly improved over the last year, although neither are quite ready for you to buy just yet.

This year, we're going to branch out a bit, and take a look two new technologies that ARPA-E has funded to try and improve our lives by saving energy.

Self-Fluffing Fabrics

The most efficient way of keeping yourself at a comfortable temperature is to simply vary the amount of insulation you're wearing. This takes no energy, because it's based entirely on controlling the amount of heat that you allow your body to radiate into the environment: if it's hot, wear a t-shirt, and if it's cold, put on a jacket. The annoying part about doing this is that you probably have multiple garments that are appropriate for multiple temperature ranges, so when the temperature changes, you have to put things on or take things off or change clothes completely.

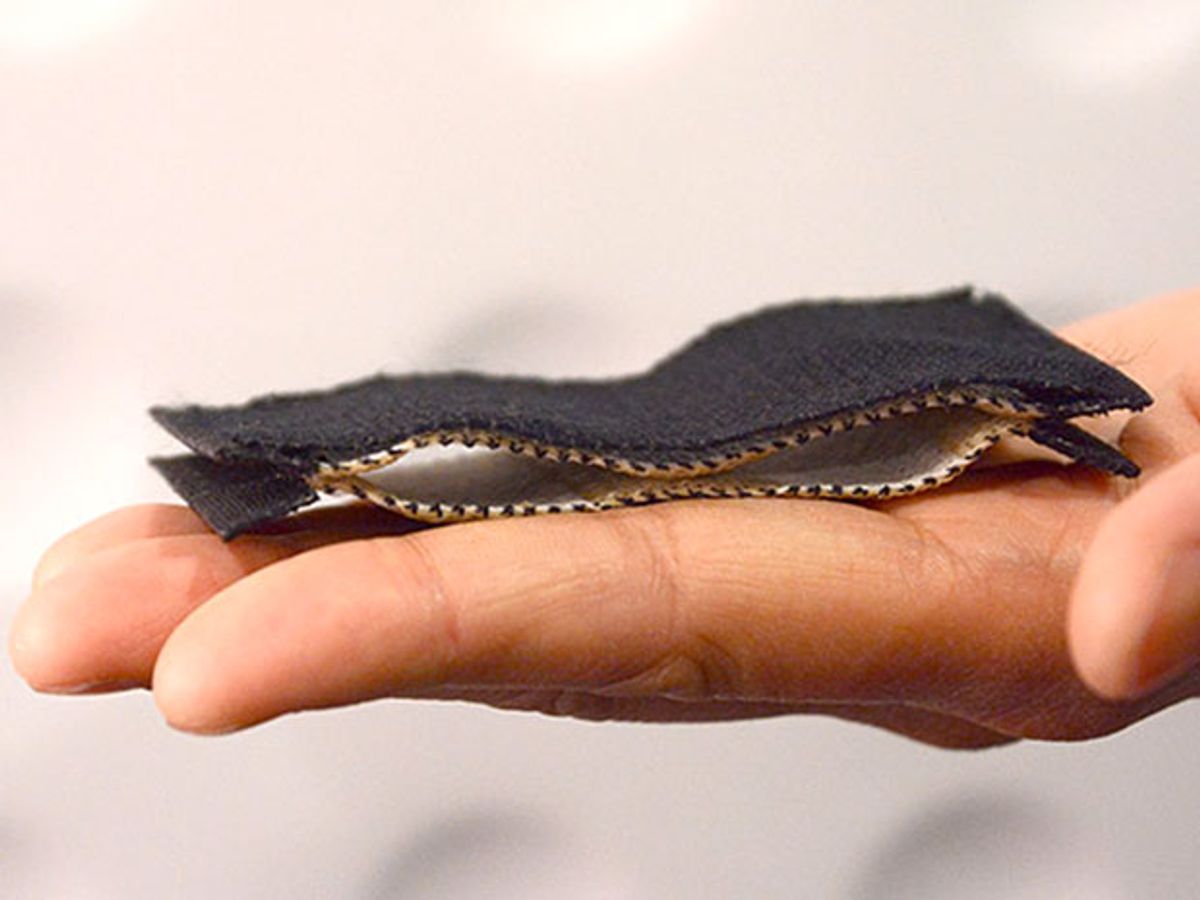

A small team at Otherlab, which does all kinds of weird things, has been using ARPA-E funding to develop what they're calling "thermally adaptive materials." We'll call it self-poofing fabric, for its ability to dynamically change its insulation in response to temperature. The idea is that the fabric will provide a small amount of insulation when it's warm out, and then increase how insulating it is (by trapping more air) in response to colder temperatures. When you see the prototype fabric in action, it looks like magic:

This video is sped up by a factor of ten, but we've seen this stuff personally, and it changes fast enough to see in real time. It might take a minute or so for the fabric to transform itself from completely flat to completely poofed, and then another minute to go back, but that's certainly quick enough to be useful. At minimum poof, the fabric insulates you about as much as a heavy t-shirt, and at maximum poof, it's equivalent to heavy outdoor gear, nearly tripling its insulating ability in response to a temperature drop of 15 degrees Celsius.

What's most exciting about Otherlab's fabric is that it operates completely passively. There's no power source, no wiring, and no controls—nothing but a combination of common synthetic fibers, each of which has different thermal expansion characteristics. With a very careful and deliberate structural layering of these fibers, one fiber expanding in response to temperature more than another causes the length of the layers in the fabric to change significantly. The result is a wavy shape that opens up insulating pockets of air. The fabric will continue to do this after it's been worn, washed, or crumpled, because there are no mechanical or electronic parts to break or chemicals to get used up. It's brilliant. And besides just making your life more pleasant and convenient, it can also save a lot of energy, according to Otherlab:

Clothing that changes insulation in response to its thermal environment has the potential to keep the wearer comfortable over a wide range of temperatures. In an office building, school, or factory where everyone wears adaptive materials, this could reduce the need for heating and cooling and significantly reduce energy consumption. By expanding heating and cooling control by 2 °C (4 °F), domestic energy consumption and related emissions can potentially be reduced by 2 percent.

Outdoors, this technology can make a commute, a hike, or travel more comfortable. Our goal is to reduce the need for bulky layers. We are working to bring comfort everywhere.

Since the fabric is made of commodity materials and the manufacturing process is just like that used to produce other fabrics, the team at Otherlab (including Brent Ridley, Jean Chang, and Leah Bryson) says that they should be able to scale up from fabric samples to actual garments within the next year.

World's Coolest Paint

We know, paint is so boring that watching it dry (which is arguably the most exciting thing that paint ever gets to do) is the absolute standard of ultimate boredom. But a new paint that Xerox PARC was demonstrating at the ARPA-E expo is literally the coolest paint we've ever seen, and it could have an enormous impact on energy efficiency all over the world.

At first glance, PARC's paint (which was developed with funding from ARPA-E's Advanced Research in Dry Cooling, or ARID, program), looks just like normal white paint. What you can't see is that the paint is brimming with two different kinds of metaparticles. One type of metaparticle reflects broadband sunlight, helping the paint to keep heat away from anything underneath it. The other type emits infrared radiation at between 8 and 13 micrometers, a wavelength that allows heat to pass straight through Earth's atmosphere and into space, dropping the paint's temperature below ambient temperature.

This combination of metaparticles is so effective at reflecting sunlight and passively radiating heat that PARC's paint is able to "self-cool" whatever it's painted on to about 10 °C (18 °F) below ambient temperatures in broad daylight. PARC tested this out with an identical pair of tents out in the desert over the course of a month, and the tent with a painted fabric roof was reliably 8 °C to 12 °C cooler than the unpainted tent next door.

The tent scenario is probably the best possible performance you'd expect out of this paint, but PARC has tested it on commercial rooftops as well, and showed that it is able to cool building interiors by about 5 °C more than top of the line reflective white paint does, and about 12 °C more than Home Depot's white paint. To be clear, you get this extra cooling by doing nothing more than painting your roof with PARC's paint. It's also cheap and easy to manufacture (it should cost the same as Home Depot’s paint), and can be sprayed on like a normal liquid paint, so there's very little reason not to use this stuff if you live in a hot climate: we're told that the average home in California could save 50 percent (!) of its energy costs for climate control. A prototype paint is already available, and thanks to a partnership with BASF, PARC expects that the paint should be commercially available soon.

This post was corrected on 11 April to give the correct wavelength of radiation. It is 8-13 micrometers (infrared) not 8-13 nanometers (extreme ultraviolet).

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.