Vanderbilt engineers want to speed up the development of capsule robots. So they have created an open-source modular platform that people with limited experience can use to build their own prototypes. Biomechatronics engineer Pietro Valdastri and his team launched the platform this summer and at least one outside research group is planning to put it to work in the coming months.

A medical capsule robot is a small, often pill-sized device that can be maneuvered inside the body after being swallowed or surgically inserted. Most prototypes use wireless electronics or magnets or a combination of the two to control the movement of the capsule. Such devices have been outfitted with cameras to allow observation and diagnosis, with grippers to take biopsies, with sensors that ‘feel,’ or palpate, the tissue, and even with mechanical needles that administer drugs.

Valdastri has designed several of his own: a swimming capsule equipped with a camera that propels itself through the stomach; a crawling capsule that takes images of the colon; and a capsule equipped with a surgical clip to stop internal bleeding in the gastrointestinal (GI) tract.

But developing capsule prototypes from scratch is costly, time-consuming and requires advanced skills in miniaturized electronics, embedded systems and soldering.

“The problem was we had to do them from scratch every time,” said Valdastri in an interview with Spectrum. “And other research groups were redeveloping those same modules from scratch, which didn’t make sense.”

Most of the capsules have the same categories of components: a microprocessor, communication submodules that link the device with the user’s intent, an energy source, sensors such as accelerometers and gyroscopes, and actuators that enable locomotion. With those categories in mind, Valdastri and his team made a modular platform in which the pieces work in concert and can be interchanged with ease without having to reinvent the proverbial wheel.

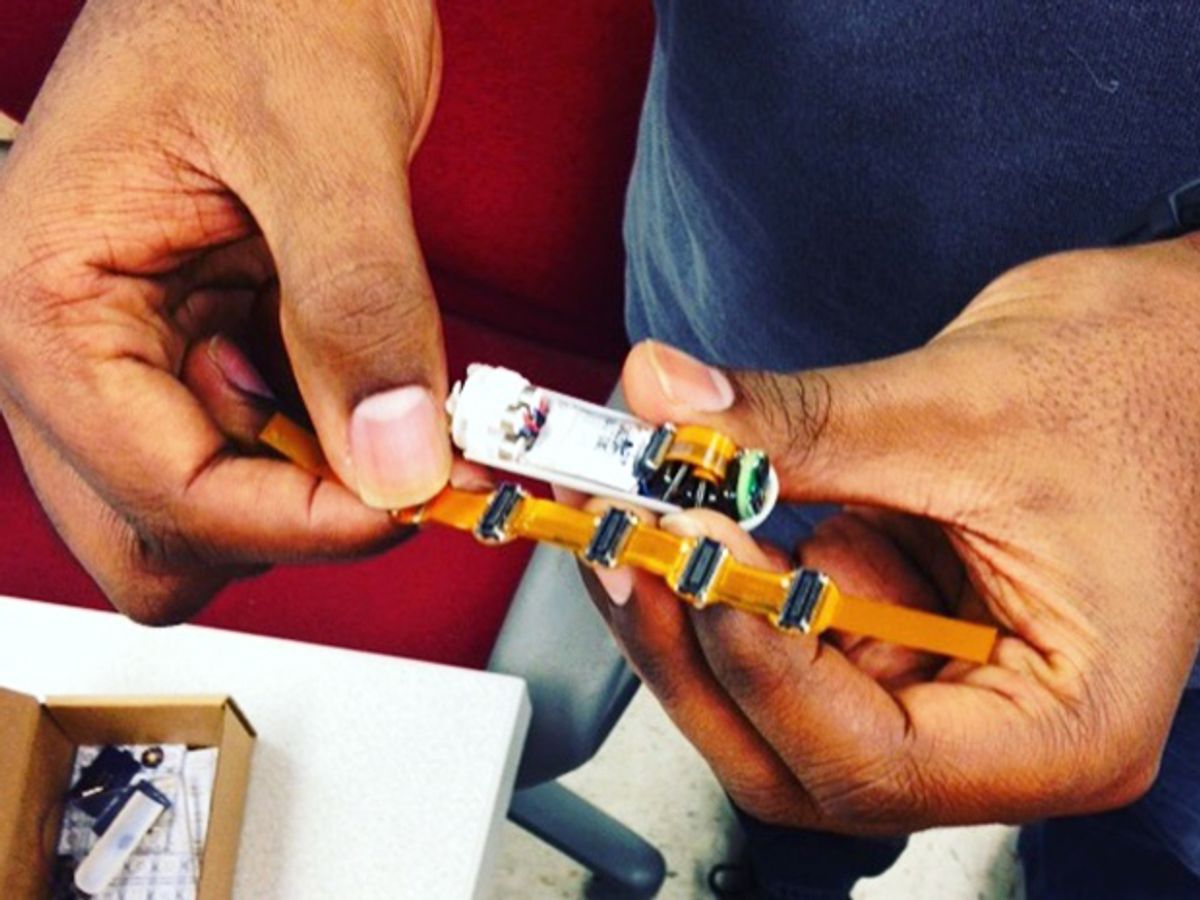

They developed a flexible circuit board on which the component parts are snapped in like Legos. The board can be folded to fit the body of the capsule, down to about 14 mm. They also compiled a library of components that designers could choose from, enabling hundreds of different combinations. Valdastri and his team arranged it all in a free online system. Designers can take the available schematics or adapt them to their specific needs, and then send the plans off to a third party for fabrication.

“Instead of redeveloping all the modules from scratch, they can use our modules and just focus on their innovation,” Valdastri said. Why make it free? “We’re supported by the National Science Foundation, so it was in the spirit of our grant proposal,” said Valdastri. It doesn’t hurt that the group will likely get some recognition from users of the system.

One research group, led by Li Zheng, an assistant professor at the Institute of Digestive Disease of the Chinese University of Hong Kong, told Spectrum that he plans for one of his students to start using the modular system in January to build miniature medical robots for GI inspection and therapy. Researchers at Scotland’s Royal Infirmary of Edinburg and Chonnam National University in South Korea have also expressed interest in using the system, Valdastri said.

For those who need an even more stripped down system, Valdastri and his team are developing a simplified version of the platform that will be geared to pre-college students and tech enthusiasts.

One limitation of Valdastri’s system is that it’s only for designing prototypes. Researchers can validate their hypotheses and do preliminary design using the platform, but will need to move to a custom approach to develop their capsules further and make them practical for clinical use.

“Systems made of modules are not optimal for a particular application and usually causes an increase in the the size of the system compared with a custom device,” Valdastri and his co-authors wrote in a September paper published in IEEE Design & Test.

There are a few non-robotically controlled digital capsule devices already on the market or in clinical use that are equipped with cameras and other functions. PillCamis an ingestible capsule with a camera on it that is used for endoscopic exploration of the colon, small bowel and esophagus. Medimetric’s Intellicap is a digital pill with pH sensors, and can release a drug at specific points in the GI tract based on the changes in pH. But these smart capsules are propelled by the digestive system, so they go where the body wants them to go, and at the body’s pace. Robotically controlled capsules can be directed and stopped, enabling researchers and surgeons to do more with them.

Emily Waltz is a features editor at Spectrum covering power and energy. Prior to joining the staff in January 2024, Emily spent 18 years as a freelance journalist covering biotechnology, primarily for the Nature research journals and Spectrum. Her work has also appeared in Scientific American, Discover, Outside, and the New York Times. Emily has a master's degree from Columbia University Graduate School of Journalism and an undergraduate degree from Vanderbilt University. With every word she writes, Emily strives to say something true and useful. She posts on Twitter/X @EmWaltz and her portfolio can be found on her website.