Nanotechnology is already having an impact on air travel, as evidenced by EasyJet’s testing of a nanocoating that will reduce wind drag and fuel consumption.

But if current research into new adhesives based on nanomaterials proves effective, the future of aircraft manufacturing could be altered significantly beyond just coatings and into the actual structures of the aircraft.

Researchers at the University of Toronto are looking into the use of multifunctional nanocomposites and adhesives that would be used in joining techniques for primary flight load structures and serve a double purpose of providing an early warning system for stresses on these structures and possible future failures.

This line of research builds on the already developing practice of using composites and adhesive bonding in the place of mechanical fastening or welding, such as with the new Airbus A380.

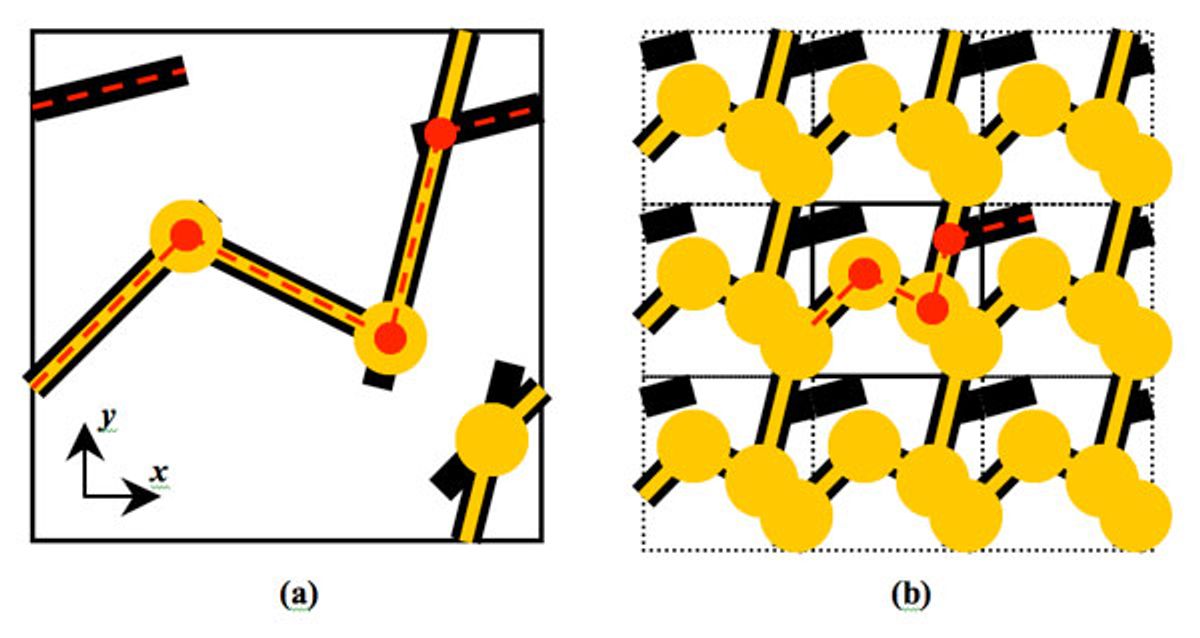

The University of Toronto researchers are working with carbon nanotubes to develop their multifunctional adhesives (smart adhesives) due to their electrical conductivity.

Earlier this year, I covered research coming out of MIT that would use carbon nanotubes in a method for detecting internal damage to composites.

In the MIT research, an electrical current would be applied to the composites that would heat up the carbon nanotubes and allow the use of thermographic camera for detecting flaws without the cumbersome need for heating the entire surface of the aircraft.

The Canadian researchers are attempting something a bit more ambitious in that the method "employs a novel network recognition approach to determine current continuity and critical percolation level."

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.