You can fry an egg on the ground in Las Vegas in August, but try that in Iceland or Alaska and you'll just end up with the stuff on your face—unless you know how to tap into the Earth's vast reservoirs of geothermal energy.

Researchers at the Tokyo Institute of Technology have developed a new kind of battery that can reliably generate electric power from heat in environments with temperatures ranging from 60 degrees C to 100 degrees C—which is low enough to mimic geothermal heat.

In an earlier experiment, the researchers developed sensitized thermal cells (STCs) that employed dye-sensitized solar cells to convert light into electric power. In their latest advance, team leader Sachiko Matsushita, an associate professor at Tokyo Tech, explained that they replaced the dye with a semiconductor to enable the cells to operate using heat instead of light.

Several methods for converting heat into electric power already exist, including redox batteries that employ the flow of hot and cold chemical liquids to create electricity, and thermoelectric batteries that use the Seebeck effect to generate electricity when a temperature gradient is applied along a conductor.

But Matsushita points out that whereas the STC battery can literally be buried in the ground and work as is, the other devices would face major physical and operational issues if required to operate in such a way.

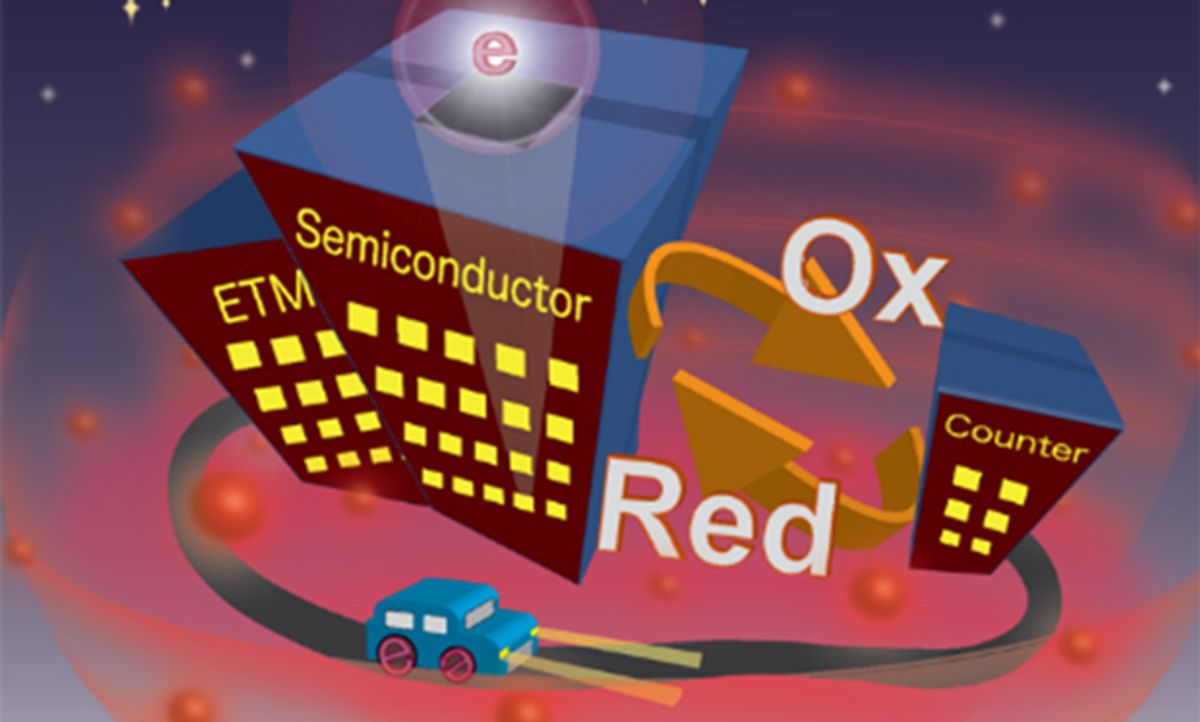

The STC consists of an electron transport layer of n-type silicon and a semiconductor layer of germanium that together compose the working electrode. Sandwiched between these layers and the counter electrode made of fluorine-doped tin-oxide glass is a solid electrolyte layer of copper ions in a polymer.

When heat is applied, electrons in the semiconductor are thermally excited and rise from a low-energy state to a high-energy state, and are injected into the electron transport layer. From there, they pass through an external circuit and continue on via the counter electrode to the electrolyte.

An oxidation and reduction (redox) reaction involving copper ions takes place in the electrolyte. This causes some low-energy electrons to be transferred back to the semiconductor layer and so the process begins anew, completing the circuit.

In testing the battery using a hot plate as the heat source, the researches connected 10 cells in series and powered an LED light. In another test, the cells were used to run a liquid crystal display.

When the team first began practical testing using an oven as the heat source, it wasn't clear if or when the battery would stop operating. After experimenting, the device did indeed stop once the redox reaction in the electrolyte halted and equilibrium was reached at both interfaces of the electrolyte, which prevented any further transfer of electrons.

But to their surprise, the researchers discovered that by simply turning off and on the external circuit while leaving the battery in the heat source, power generation was restored. This happens because when the circuit is turned off, the reduction reaction in the electrolyte dissipates. Consequently, ion distribution in the electrolyte changes and equilibrium is no longer maintained. Thus power generation begins again.

"In other words," said Matsushita, "though the STC is not a perpetual energy generator, it can operate semi-permanently in a heat source by turning a switch on and off."

To make this work in a practical sense, she said two batteries could be buried together in a heat source with either device being used to switch the other on or off as a way to provide continual current.

Going forward, the researchers aim to improve the stability of the electrolyte, and also to increase the amount of current generated by increasing the surface of the semiconductor material used.

As for commercial prospects, the researchers are working with Sanoh Industrial Co. Ltd., an automotive and metal parts maker in Tokyo. After further refinement of the device, they plan to apply the technology first as a means of self-powering sensors that can be employed wherever heat is readily available, such as in vehicles and in factory equipment. Then, they will develop the technology to provide power for larger-scale applications.

"The STC does not rely on the wind; it doesn't produce radiation; it doesn't require oil to run; and, unlike solar power, it can provide stable power generation day and night simply by burying it in a heat source," says Matsushita. "We believe it will open up new academic fields based on thermodynamics and electrochemistry and so extend the reach of electrical engineering and chemical engineering."