THE INSTITUTEThe delivery of digital communications to remote parts of the world, mostly in developing countries, has been a challenge for private telecommunication companies and international development organizations alike. The former struggles with the lack of business opportunities in sparsely populated areas and the latter with the challenges of unsustainable ad-hoc projects that do not go beyond early funding stages. This is further complicated by the fact that these areas face extreme poverty, disease, a struggle for daily sustenance, and social and religious realities that make them different from Western models and require more than a "home improvement approach.”

In such scenarios, most citizens cannot afford the cost of a mobile device or Internet service. The lack of clean water, sanitation, health care, electricity, and food take priority. By bringing digital telecommunications and Internet access to these parts of the world, people can get the knowledge and empowerment that could lead them to economic opportunities.

One of IEEE’s biggest humanitarian initiatives, the Humanitarian Technology Challenge, identified data connectivity for remote health offices as one of the top three solutions (or tools) that will contribute to reaching the Millennium Development Goals (MDGs) set forth by the United Nations and its partners with aims to reduce poverty and disease around the world.

By implementing adequate technologies, remote health posts—which are makeshift clinics generally staffed by a medical technician—could, for example, have better communication systems with central hospitals from larger villages that are often miles away in order to get second opinions, step-by step guidance on how to treat a patient, information about medical supplies, and training from doctors and specialists.

In the absence of such communications, remote areas are left isolated and incapable of taking care of patients when emergencies and complications arise, during childbirth, for example. Some of these remote villages can be a day’s boat rideaway from the nearest hospital, and at times such trips cannot even be made because river levels are too low.

Although some of these areas do receive limited mobile phone reception and, at times, Internet access, the services are saturated and intermittent and do not provide appropriate bandwidth for voice, least video, communications. In these areas, a 2 megabyte file can take as long as 30 minutes to download. This reality is not going to easily change in the coming years. But a group of committed IEEE volunteers are trying to do what they can to help.

DEVELOPING THE MODEL

The IEEE initiative that I was part of, called the IEEE Humanitarian Technology Challenge, set forth three main challenges. One of them, the Data Connectivity Solution, gave birth to various initiatives including an e-Health project in the Peruvian Amazon, which is now a blueprint for similar projects that are currently being carried out in various parts of the Bolivian Andes.

The Peruvian Amazon project worked with local partners and technologies to help fulfill the key health needs of remote communities. The IEEE Data Connectivity Solution (also known as the Data Connectivity Initiative) partnered with four important groups: The Peruvian Grupo de Telecommunicaciones Rurales from Catholic University of Peru, Alto Amazonas Health Network, local municipalities, and local indigenous groups. These partnerships helped us learn from local experts about technical and health-related issues, as well as the sustainability potential of our project.

Remote health posts that have only one medical technician can now conduct an examination and provide a diagnosis for patients by connecting with medical doctors and specialists from several villages away. Now these health centers have access to high-resolution video conferencing, data streaming, and of course, Internet. The infrastructure has also been used to exchange patient data, monitor medical supplies, and has even helped mitigate feelings of isolation for personnel who work in these remote areas because they can communicate with their families who live in the larger villages.

The project has literally saved lives and has turned into an important component of health care in those remote areas. Several institutions have implemented data connectivity in their centers, and the government adopted better policies to promote telehealth. The Peru project has been operating for more than two years with the help of local and regional IEEE volunteers and with the guidance of the Grupo de Telecomunicaciones Rurales.

To accomplish this goal, we used inexpensive Wi-Fi technology that can reach long distances and connect to various health centers approximately 40 kilometers away from each other. The massive infrastructure consists of 60-meter (approximately 200 feet) towers that hold radios, antennas, solar panels, and batteries that provide Internet service 24/7 to the region. We must note, however, that technology has only been a small part of the overall solution. It is worth underlining that when we mention “project” or “implementation,” we refer to a broad categorization of activities that includes social, political, technical, and cultural efforts.

THE BOLIVIA PROJECT

In order to apply the Peruvian model to the remote Andes regions in Bolivia we had to go about it the same way. No two countries are alike, however, and the Bolivia project introduced us to new challenges. First, we could not find a Bolivian organization with expertise in the utilization of long-distance telecommunications focused on telehealth. To solve this problem, we partnered with the IEEE Bolivia section that provided passionate volunteers who were willing to participate in the project for several years. Those volunteers made visits to the areas in Peru where we worked and participated in regional meetings. Moreover, they helped us develop a plan for the initial stages of the project.

Some challenges that we faced included the high winds of the Andes regions, higher costs than in Peru for specialized supplies, and the complexities of directing funding for the project. The biggest challenge for us was the country’s spectrum regulations. The transmission of certain ISM (industrial, scientific, and medical radio band) frequencies can incur high costs and long waits. The Bolivian volunteers, through visits with political leaders and policymakers, participated in efforts toward changing these government policies to provide important communication services to underserved areas of the nation. Because of these efforts, this hurdle has been cleared and the region can now operate in such frequencies.

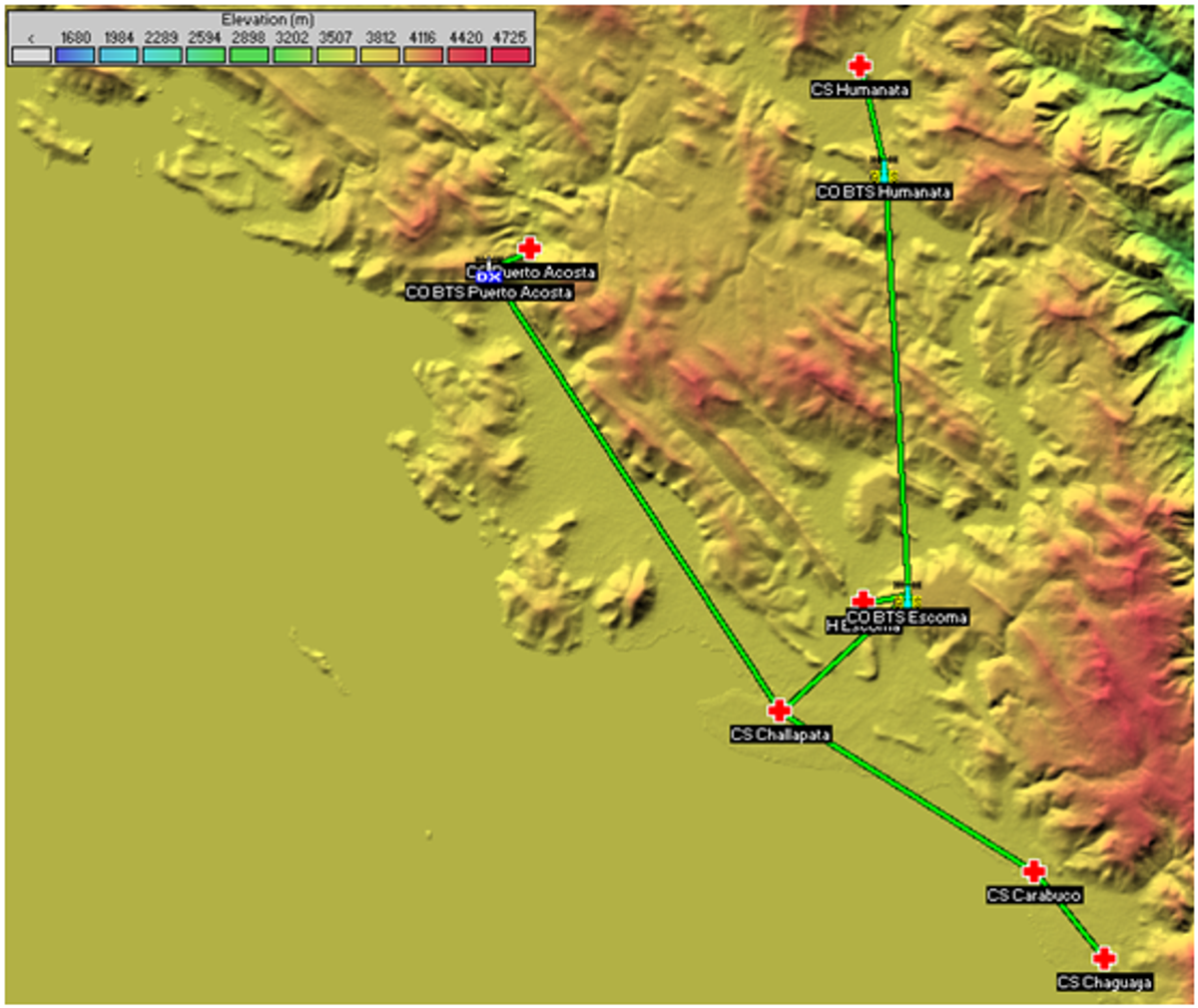

The first stage of this project, comprised of four health offices, was completed in July 2013. The next stage begins in the coming weeks. It will focus on expanding digital access to other health centers through the challenging Andes to the outskirts of Lake Titikaka, an area that more than 2000 years ago gave birth to the Tiwanaco civilization, which was characterized by their advanced astronomy and engineering knowledge. The initiative will then expand services to schools, as well as small communities that will profit from Internet access by making it easier for them to export their products.

Martin Murillo is a researcher focused on electronic data for government use and government transparency. He is also involved in data connectivity infrastructure in remote areas and has published his work in several journals on topics of optimal control, wireless systems, and political science.