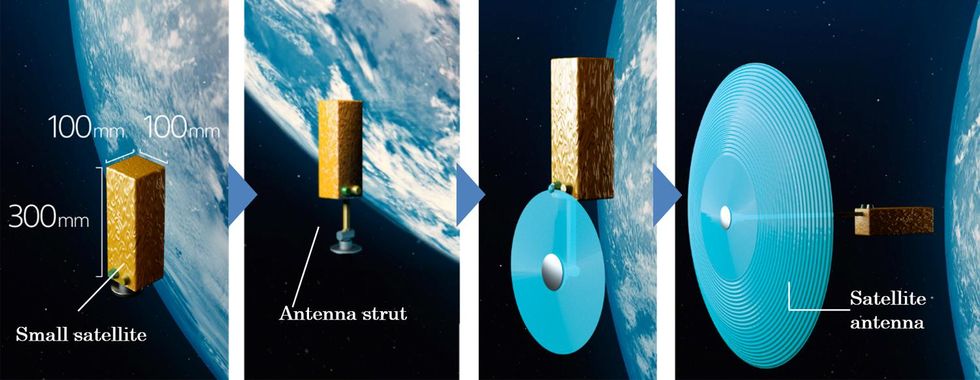

A crucial part of any satellite launched into orbit is its antenna. The challenge, however, is that its (typically) dish-shaped antenna is big, heavy, and difficult to fit comfortably into any reasonably-sized rocket fairing. So researchers at Mitsubishi Electric Research Laboratories (MERL) in Cambridge, Mass., wondered, What if satellites simply skip over the whole problem? That is, don’t bring an entire, oversize antenna assembly up into space with the satellite but instead 3D print it once the satellite reaches orbit.

MERL has in fact developed an on-orbit, antenna 3D-printing technology that uses photosensitive resin, hardened by solar ultraviolet light. The new technique, the researchers say, potentially allows the dish to achieve high gain and wide bandwidth (which requires a large antenna), while still keeping the satellite that’s launched from Earth lightweight and small.

Printing the antenna on orbit solves another big problem, too: Satellites launched from the ground undergo enormous vibrational pressure during takeoff. So every part of the satellite—including the antenna dish and mount—has to be overbuilt to withstand the intense stress. This adds to the antenna’s weight and cost, and therefore the cost of the launch.

Of course, if the antenna is manufactured in space, none of these difficulties ever need bother the engineers designing the satellite.

As a case study, MERL researchers considered NASA and the European Space Agency’s Cassini-Huygens spacecraft—whose exceptionally large antenna measured 4 meters across and weighed 105 kilograms. If Cassini-Huygens (launched in 1997) could have substituted its oversize dish with an antenna that could have been fabricated in space, the spacecraft would have saved 80 precious kilograms of launch weight, translating to a launch-cost savings of 80 percent on the antenna and antenna-mount weight.

“It’s about as viscous as honey, sticks like glue, and hardens like a rock in a few seconds in the sun.”

—William Yerazunis, Mitsubishi Electric Research Laboratories

“Yet even with smaller satellites, we estimate the reduced weight will [still] make a significant difference,” says William Yerazunis, senior principal researcher at MERL. “Right now, United Launch Alliance is charging US $73 million to put 15 metric tons into low earth orbit. If we can reduce the overall payload by even 5 percent, that would be a savings of $3.5 million with multiple launches.”

A key element of the cost-saving technology involves developing the right resin, the researchers note. “If you put standard resins in a vacuum chamber, they boil away and contaminate everything nearby,” says Avishai Weiss, principal research scientist at MERL.

Instead, the researchers developed a photosensitive resin that can be extruded and cured into a rigid solid in a vacuum—a world’s first, according to the company. As well as being heat-resistant to at least 400 °C, “it’s about as viscous as honey, sticks like glue, and hardens like a rock in a few seconds in the sun,” says Yerazunis. And, he says, it’s no more expensive to create than any of the already existing resins on the market.

“In general, on-orbit fabrication of antennas and other structures in space is a promising technology,” says Professor Saburo Matunaga, who researches in-space systems engineering and small satellite systems development at the Tokyo Institute of Technology. “Mitsubishi Electric‘s prototype 3D printing looks to be a good first step because the UV curable resin appears to have the characteristics of stable extrusion and rigidization in the environment of a vacuum, and it is heat resistant to a high degree.”

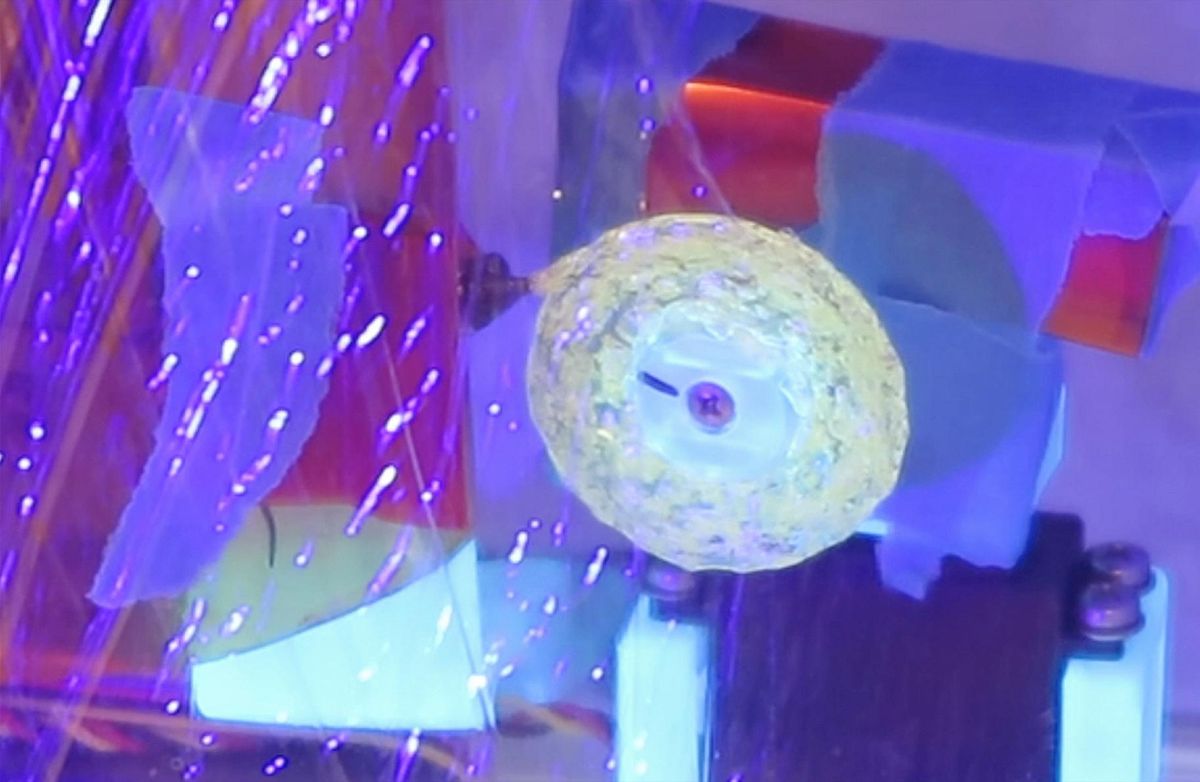

The MERL researchers say their new antenna fabrication process involves first creating the antenna structure and then coating it with the metallic layer that enables it to reflect. A motor turns the hub of the antenna-to-be, while the resin valve opens—allowing a trail of resin to spiral out from the hub, ultimately into the dish’s parabolic shape. The sun’s UV light, they say, hardens the resin within a few seconds upon extrusion.

The process continues, until a dish of concentric layers of hardened resin is completed. Finally, a layer of conductive metallization is applied through vacuum metallization via a second nozzle that boils aluminum and sends the vapor out in a stream that coats the entire dish—the same process that coats potato chip bags with a superthin layer of aluminum to keep the chips fresh.

On-orbit 3D Printing Technology for Fabrication of Satellite Antennaswww.youtube.com

In their (terrestrial) lab, the MERL team has already printed small parabolic dishes in a vacuum, while a 165 millimeter-diameter dish they printed in air yielded a working antenna with a gain of 23.5 decibels at 13.5 gigahertz in the Ku communication band.

They expect next to test the technology at full scale using a larger dish in a thermal vacuum chamber at a low-earth-orbit-level of vacuum—and then ultimately to test it out on a cubesat platform in orbit. The team says to expect this technology to become commercially available within five years.

An advanced version of the technology, Matunaga says, will eventually be used “to fabricate and assemble other fundamental parts of a satellite’s structure, such as the antenna support structure and truss elements, which would further reduce weight and the cost of launch.”

- 3D-Printed Thruster Boosts Range of CubeSat Applications - IEEE ... ›

- Two Companies Team Up to Send 3D Bioprinter to the Space ... ›