The closest thing we have right now to a Star Trek–style tractor beam is a technology based on moving small objects with sound. Last year, researchers from the Public University of Navarre, in Spain, demonstrated how ultrasonic acoustic holograms can be used to manipulate things in midair, using arrays of ultrasonic transducers and some reasonably complicated modeling and programming. The overall complexity of the acoustic hologram—a 3D structure made of sound—that you can create in this way (and consequently what you can do with it) is limited primarily by the characteristics of your transducer array, and because transducers can only get so small, this is a significant limitation.

An acoustic hologram manifests itself as variations in air pressure. You can make pressure structures like vortices and bottles, which can trap small, lightweight things in areas of low pressure inside areas of high pressure. Creating the structures involves the creation of a sound field where a bunch of different sound waves of varying amplitudes constructively and destructively interfere in just the right way to make exactly the structure that you want. One way to do this is with an array of individual transducers, each one emitting a slightly different sound wave.

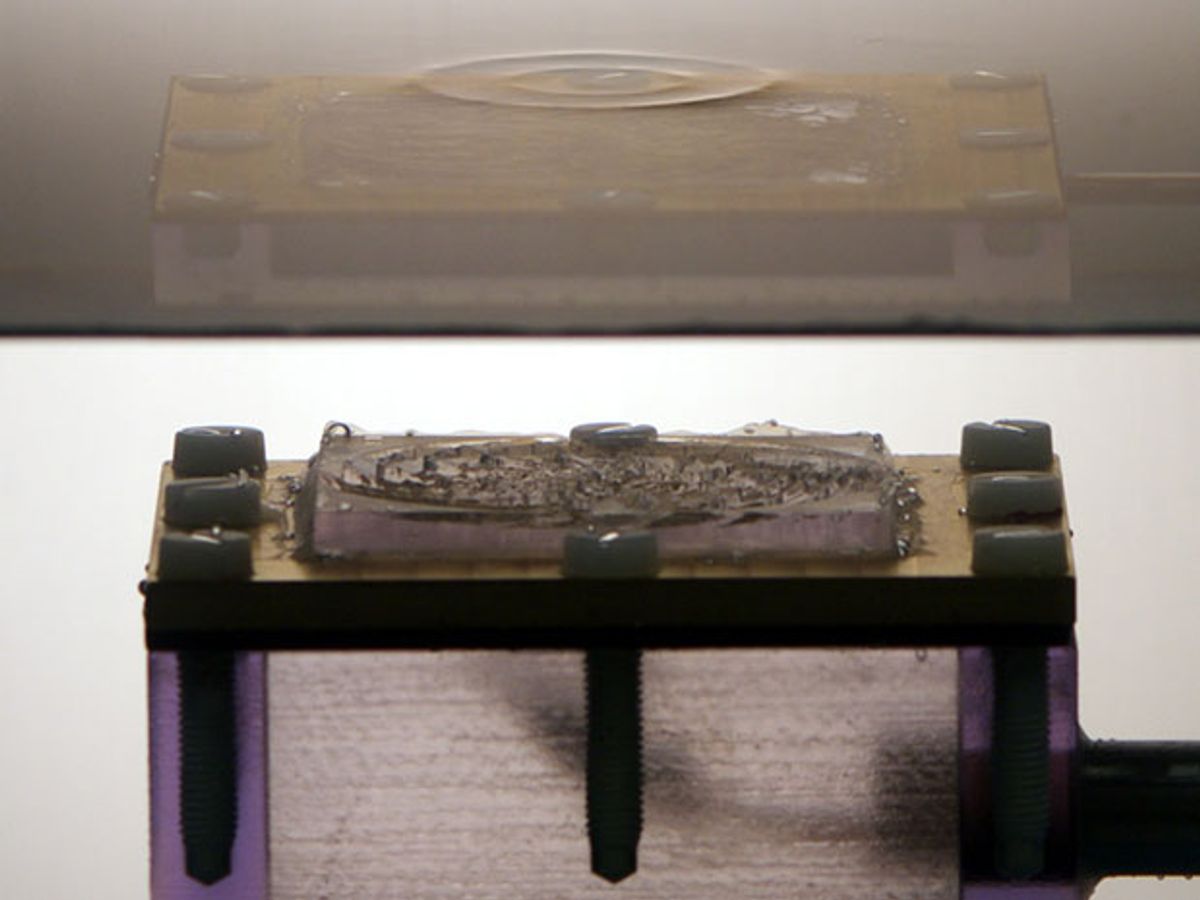

But in a paper published in Nature this week, a team from the Max Planck Institute for Intelligent Systems, in Germany, describe a new way of easily creating very high resolution acoustic holograms that work in air or water. Rather than relying on a whole bunch of small transducers, they use just one giant transducer instead. It sits underneath a special 3D-printed transmission hologram made out of finely contoured plastic.

In this new research, the single transducer emits one type of sound wave, which means that you can't use it to create a sound field that'll do all that much for you. What the researchers realized, however, is that the only important thing is finding a way to generate all of those different sound waves—which you can do without more than one transducer if you're clever and willing to make a few compromises.

The trick is to use a 3D-printed hunk o’ plastic. Or, to get needlessly technical, a “3D-printed monolithic element.” Or, to get less needlessly technical, “a finely contoured solid plastic block.” The block is attached to the transducer, and when it transduces, the sound wave has to propagate through the block before it's emitted into space. Since sound moves slower through the block than it does through air or water, by carefully printing the top of the block in a very specific pattern to vary its thickness, you get the same effect as using a transducer array made up of individual transducers that are each as small as the resolution of your 3D printer. This allows the creation of acoustic holograms that are about 100 times as detailed as anyone has been able to make before.

In common use, the word “hologram” refers to a structured field of light or sound, but it can also refer to the spatial storage of a wave front in a way that allows the characteristics of that wave front to be reconstructed when you pump some energy back through the storage medium. In this particular case, the “hologram” is the plastic block, which converts a sound wave from a single transducer into a complex sound field.

The obvious downside with this technique is that you can't dynamically change the acoustic field, since it's fixed by the 3D-printed plastic plate. You can set up acoustic fields that move objects, but they'll move along a fixed path. One potential workaround is 3D printing a single hologram that encodes multiple sound fields at different frequencies. That would allow you to dynamically select the hologram by twiddling the transducer.

In terms of practical applications, the researchers mention super-resolution imaging, selective heating, and personalized medicine. But what's most relevant here is the fact that it's now very quick, easy, and cheap to create ultrahigh resolution acoustic hologram-based tractor beams for that spaceship that I'm totally not secretly building in my garage.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.