No sooner do I discuss University of Illinois researchers who have created 3D antennas for mobile phones using nanotechnology than another group of researchers at the University of Illinois (this time at Urbana-Champaign) have developed 3D material for batteries that combines the qualities of supercapacitors with those of batteries and could change the entire battery paradigm.

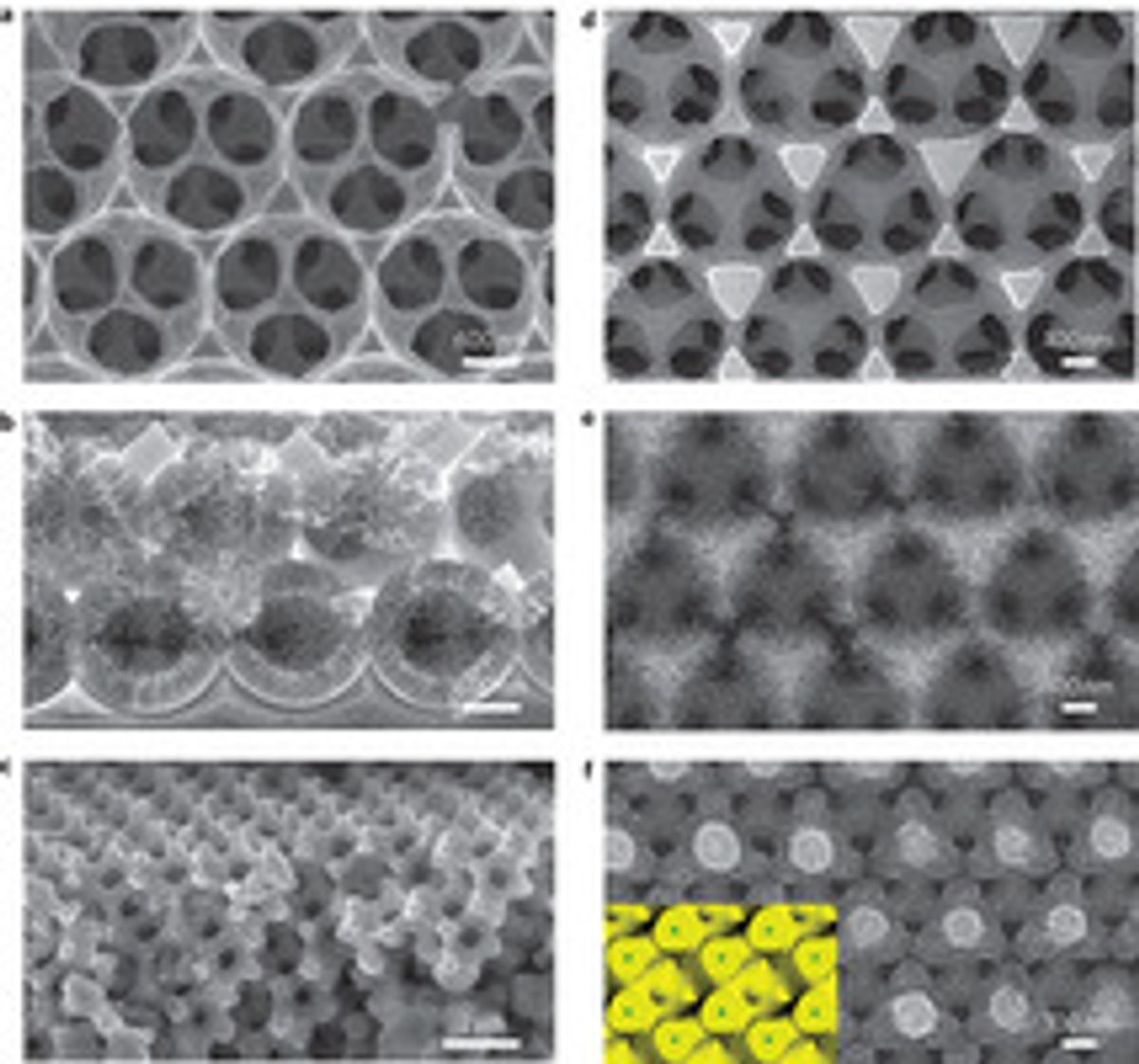

Professor Paul Braun and his colleagues just published in the March 20th edition of the journal Nature Nanotechnology their results that showed ultra fast charge and discharge rates by “using cathodes made from a self-assembled three-dimensional bicontinuous nanoarchitecture consisting of an electrolytically active material sandwiched between rapid ion and electron transport pathways.”

What this could mean, according to the excited science and technology press, are electric cars that could be charged in five minutes, a laptop in just a couple of minutes and a cell phone in seconds.While thin film technology has allowed faster charging capabilities than seen in your typical li-ion batteries but it can’t store the energy well, meaning that a mobile device would run out of power in mere seconds. What Braun and his team have done essentially is to take the thin film technology but built it up through self-assembly into a three-dimensional structure thereby increasing its surface area and its ability to store energy.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.