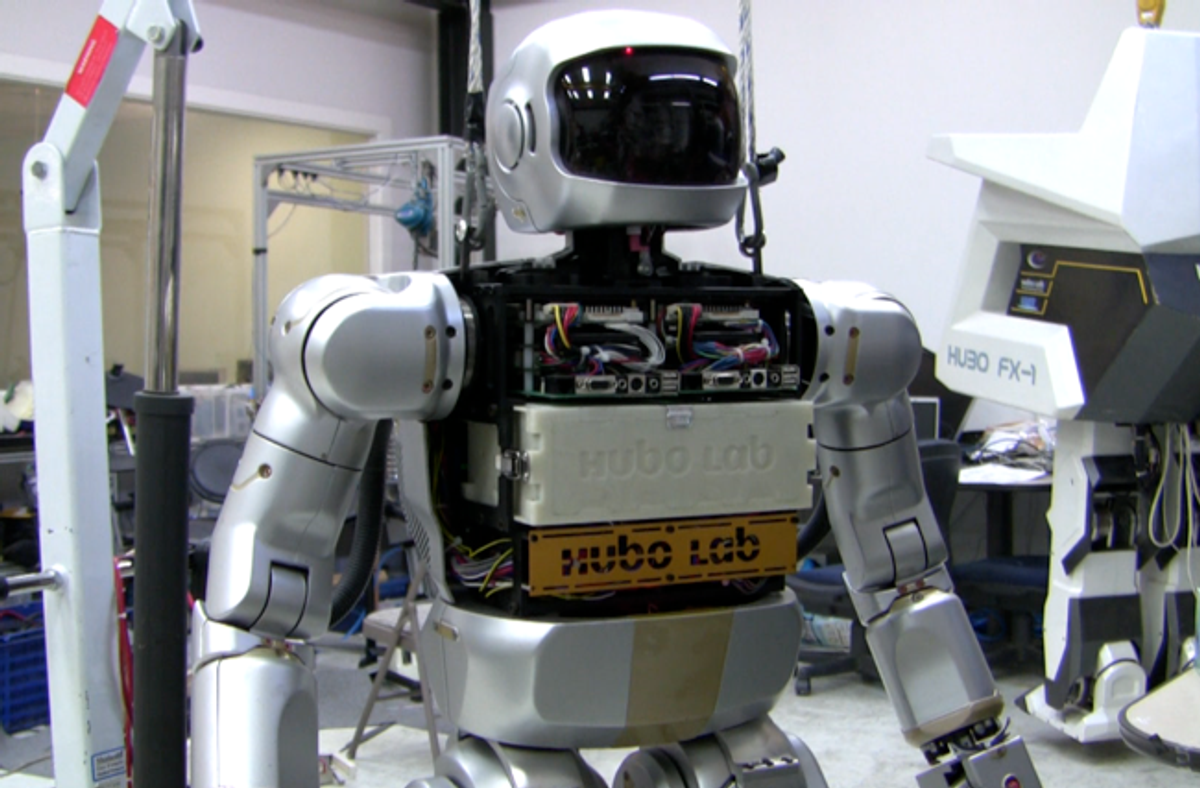

It's Hubo II, the humanoid above, which Oh and his colleagues developed at the Korea Advanced Institute of Science and Technology's Humanoid Robot Research Center, aka Hubo Lab.

Professor Oh built the original Hubo in 2004. It was one of the first advanced full-body humanoid robots developed outside Japan. But he's probably better known for another humanoid: Albert Hubo, which had a Hubo body and an Albert Einstein animatronic head developed by Hanson Robotics.

Now Professor Oh is ready to introduce the new addition to his family. Hubo II is lighter and faster than its older brother, weighing 45 kilograms, or a third less, and capable of walking two times faster.

Watch the demo:

A major improvement over early humanoid designs is Hubo II's gait. Most humanoid robots walk with their knees bent, which is dynamically more stable but not natural compared to human walking. Hubo II, Professor Oh says, performs straight leg walking. It consumes less energy and allows for faster walking. Note Hubo II's left knee extended when the leg swings forward (middle image below):

The robot has more than 40 motors and dozens of sensors, cameras, and controllers. It carries a lithium polymer battery with a 480 watt-hour capacity, which keeps the robot running up 2 hours with movement and up to 7 hours without movement.

Hubo II uses two identical PC104 embedded computers with solid state hard disks and connected via a serial interface. The left one can control the entire robot, taking care of functions like walking and overall stabilization; the right one is normally empty and you can load speech, vision, and navigation algorithms to see how they perform on Hubo.

Another improvement is the hand design. It weighs only 380 grams and has five motors and a torque sensor. It can handle any object that fits on its palm, and its wrist can rotate in a humanlike way.

Talking with Professor Oh made me appreciate how difficult humanoid projects are. The challenge, he told me, is not just cramming all the hardware into a tight space, but also making sure everything works together. Cables can unexpectedly restrict joint movements; power and control boards interfere with each other; modules end up too heavy and create instability.

So many things can go wrong. The problem is that, whereas in a wheeled robot a failure usually means the robot stops on its tracks, in a humanoid robot failure often means a face-plant.

PS: Wondering what happened to Albert Hubo? It has a cameo appearance in the video above, watch until the end...

Erico Guizzo is the director of digital innovation at IEEE Spectrum, and cofounder of the IEEE Robots Guide, an award-winning interactive site about robotics. He oversees the operation, integration, and new feature development for all digital properties and platforms, including the Spectrum website, newsletters, CMS, editorial workflow systems, and analytics and AI tools. An IEEE Member, he is an electrical engineer by training and has a master’s degree in science writing from MIT.