Stop That Train!

Electronically controlled railway brakes may finally displace a 150-year-old technology

George Westinghouse’s many inventions rank him with Thomas A. Edison and Werner von Siemens as founding fathers of our electrified world. Yet, ironically, Westinghouse’s first invention, a railroad brake he patented in 1869, was actuated not by electrons but by air. To this day, most railroads rely on that system’s principle of releasing air from a pressurized pipe that runs the length of the train and brakes the cars one after the other, at a rate of 152 meters per second.

To compound the irony, some of Westinghouse’s early competitors proposed electrical mechanisms, but Westinghouse himself rejected these as unreliable. In the past decade, however, the idea has reemerged in a hybrid system that uses an electronic system to control a pneumatic one, so as to set the brakes in all the cars simultaneously. So obvious are the advantages of the new technology—called electronically controlled pneumatic braking, or ECP for short—that its manufacturers are optimistic it will eventually sweep the field.

“We believe that the benefits of ECP will be clearly proven,” says Robert Bourg, vice president and general manager of Wabtec Railway Electronics, in Germantown, Md. The parent company, Wabtec Corp., headquartered in Wilmerding, Penn., and the successor to the Westinghouse Air Brake Company, is one of two American companies bringing electronic-pneumatic train brakes to market. The other is New York Air Brake (NYAB), a subsidiary of Germany’s Knorr-Bremse, in Munich.

Two major U.S. railroads have recently begun running , one using Wabtec’s, the other NYAB’s. If ECP brakes catch on here, they’ll likely appear on heavy-haul railroads around the world, especially in regions that adhere to American Association of Railroads (AAR) standards, including southern Africa, Brazil, Australia, even China.

But will ECP, in fact, catch on? Believe it or not, its ultimate victory is not a foregone conclusion. Standing in the way of implementation are steep up-front investment costs and disagreements over who should shoulder them. Such impediments appear whenever an insurgent technology challenges an incumbent—for example, digital projectors in movie theaters and digital TVs in living rooms. And of course, market forces are not the only actors here. Railroads are heavily regulated—and regulation can make all the difference.

The Westinghouse air brake, though updated periodically, retains the basic character it’s had since the 1870s, even as trains have grown much longer and heavier. The locomotive forces air into a pipe that runs the length of the train and connects to a triple valve in each car; that valve connects both to the car’s auxiliary air tank and to its brake cylinder. The relative pressure of the air in the three devices determines the action.

To activate the brake, the engineer drains air from the pipe, causing a disequilibrium of pressure in the valve that moves a piston, which opens a passage from the reservoir tank to the cylinder; this opening, in turn, allows the air to rush in and set the brake. This is a fail-safe design, because if the train were somehow to break in two, the rupture in the pipe would automatically apply the brakes. To release the brake, the engineer sends air down the pipe once again, which fills each car’s reservoir in sequence.

But all this takes time—a 100-car train traveling at 80 kilometers an hour would require at least 1 km to stop. It also takes time to undo the process and get the train moving again.

“We’ve had long trains where the engineer released the brake and started pulling a little bit too early, while the brakes were still set on the rear of the train,” explains Dana Maryott, director of locomotive and air-brake systems at the Burlington Northern Santa Fe (BNSF) Railway. “And coming around a sharp radius, we’ve literally pulled the train off the track.”

Taking a freight train down a long incline is particularly complicated because air brakes cannot be gradually released, the way they are in an automobile, for example. If you try to increase the pressure in the air pipe just a little, the signal will decay after about 600 meters, and it will never reach the brakes in the rear.

To get a feel for the old Westinghouse system, I’ve come to Bluefield, W.Va., at the eastern end of the Norfolk Southern Railway’s Pocahontas Division, 167 km uphill from Roanoke, Va., and another 450 km from the great shipyards of Norfolk and Newport News. Bluefield is America’s oldest “hump yard”; it straddles the crest of a low mountain, so that cars unhitched from the locomotive will roll down to switches where they can be shunted onto the desired tracks.

Today, arriving engineers still drape their trains over the crest so that half the train is parked on each side of the hill. “Once you start heading down,” says Mike Allran, a senior engineering specialist with Norfolk Southern, “gravity’s really going to start pulling on that train good. That’s what makes it tough getting off the mountain out here.”

Sometime after 1 p.m., Train 762—two long black locomotives pulling 110 shiny aluminum cars, each heaped with over 90 000 kilograms of West Virginia coal—arrives at the Bluefield crest. The train, bound for the power plant at Hyco Lake, N.C., stretches nearly 2 km and weighs nearly 18 million kg. I climb aboard Engine 9191, along with Allran, road foreman Chuck Peters, and engineer Jeff Hayslett, while conductor Norris Kasey takes his brake stick and walks alongside the train setting air retainer valves on 10 cars. The valves reserve about 62 kilopascals of air in each brake cylinder, just in case; those cars will be slightly braked all the way to Roanoke. A few minutes later, Hayslett radios his dispatcher and then turns to the rest of us. “Everybody ready to roll?” he asks, and he begins ringing the engine’s bell.

Hayslett eases into his throttle to pull us over the hump, but it isn’t long before he turns to the brakes. The Norfolk Southern, like most U.S. railroads, teaches engineers to control the train as much as possible with the locomotives’ dynamic brakes, which slow the engines by reversing the electric current that powers their traction motors.

In practice, this means Hayslett uses the air brakes to set a base level of braking and the dynamic braking to modulate it. But here the air requires its own precision: If you’re short a couple of pounds per square inch, the train might get away. (One pound per square inch is just under 7 kPa.) But if you’re a couple of pounds over the mark, the train will stall, and you’ll have to fully release the brakes (or “knock off the air”) and then set them up again, probably before the reservoirs are fully charged. In the cab it’s known as “pissing away your air.”

“If you get your train set up the first time right, it means when you go down the mountain you ain’t gotta fight the train,” Hayslett explains. Otherwise “the train’s gonna be working you instead of you working it.”

He applies the dynamic brake, and we can feel a great number of gentle bumps as each hopper rolls into the one that preceded it. A few minutes later, with the train bunched up and the speed approaching 21 km/h, Hayslett grips a lever with two hands and reduces the brake pipe air by 8 pounds. His plan is to knock the air off at milepost N350, a flat spot in the grade where he’ll have time to recharge the system before setting the brakes up again. Next he’ll release the brakes again at Oakvale, W.Va., and then again several miles later, at the start of a very long stretch of flat running.

We breeze through the Virginia countryside. It’s a bright day in May, cool and green in the mountains. At Glen Lyn we meet the New River and follow its winding, tree-shrouded banks, first on one side, then on the other, for the next couple of hours. Then, after a long slog up a 16-km hill, we approach the entrance to the Merrimac Tunnel. Burrowing down for 1.5 km, with a grade of just over 1 percent, the tunnel presents an unusual braking challenge. Without braking, the train will gather momentum quickly. But Hayslett can’t apply the air brakes while he’s in the tunnel.

“Anytime you put the air on, you’re subject for something to go wrong,” explains Peters. Peters is thinking specifically of what’s called a kicker, a sticking valve so sensitive to a reduction in brake-pipe pressure that it begins emergency braking and “kicks” the train swiftly to a halt. Braking miscues like this are called undesired emergencies, and they’ve grown more irksome for railroads in the last 20 years.

Traveling at 32 km/h, our train could stop in as little as 20 seconds if the brakes were applied at full force, Allran supposes. But then the forces acting on the train might be severe enough to cause it to derail. “You don’t want to do that in the tunnel,” Allran says. It’s a matter of fine judgment, notes Peters, who adds that of the 94 engineers he supervises, “there are three or four I wouldn’t want to go down the mountain with.”

Any system dependent on continual human intervention can only be refined so much. By the early 1990s, “the railroad industry recognized that the current air-brake system was an extremely mature technology,” says Fred Carlson, who recently retired as a research engineer for the AAR. “There was very, very little room for improvement.”

In 1991, Dana Maryott and his colleagues at Burlington Northern approached TSM, a small company based in Kansas City, Mo., to develop electronically controlled air brakes. A 65-car coal train, known as a unit train because the cars stay together over many runs, made its debut in October 1993. (New York City’s Metro-North commuter railroad and some other relatively short and interconnected commuter trains, in Europe as well as the United States, have for decades used a fairly rudimentary electropneumatic brake system, but it’s not the one visualized for long freight trains.)

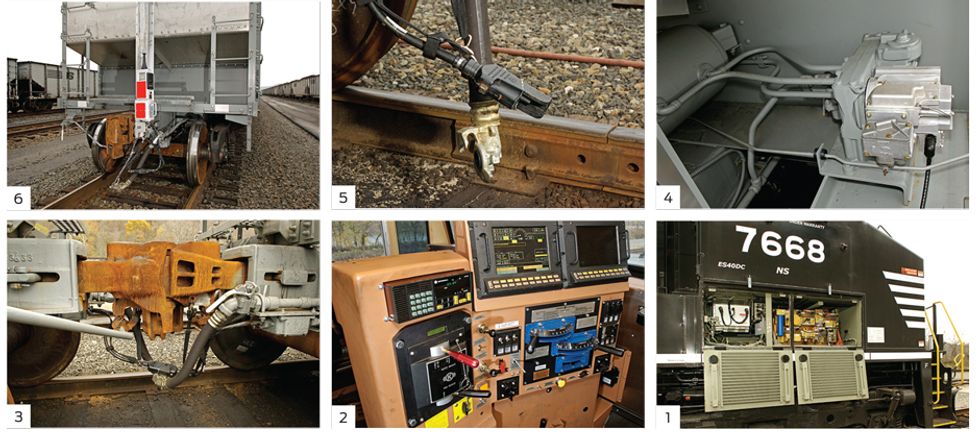

Within two years, the line began experimenting with four more such ECP trains. Each car had a manifold that outwardly resembled the old triple valve, but the system took its cues from a portable computer that stored the car’s unique ID and some performance characteristics, such as its empty and loaded weights. The car control devices, as they came to be called, were in turn controlled by a computer in the locomotive.

In 1995, the AAR, which was separately investigating alternatives to air brakes, convened a committee of railroaders and brake suppliers to write the standards that would govern the new system’s performance and interoperability. They soon faced a fundamental choice: Should the electronic signal to the computer on each car be transmitted by wire or radio?

A wire, like a conventional brake pipe, would need to run uninterrupted the length of the train, meaning that every car would need to be equipped with the new system—a potential logistical quagmire for American railroads, which constantly swap equipment with one another. But a wireless system posed its own problems. Not only would a radio-controlled system require more power (to support the radio in addition to the control circuits), but each car would have to have a power source of its own robust enough to withstand a rugged, moving environment. “We looked at axle generators, air generators, and solar power,” recalls Bryan McLaughlin, who led the ECP team at New York Air Brake, “and none of that technology was reliable and cost-effective enough to put on the cars.”

Moreover, “you need a lot of redundancy and a lot of security for the messaging so that it doesn’t get jammed,” adds the AAR’s Carlson, who coordinated the committee. “Very early on, we had a lot of communications people tell us that if you can do it with a cable, do it with a cable.”

Ultimately, the AAR did do it with a cable, choosing a power-line transceiver by Echelon Corp. , a San Jose, Calif.–based supplier of network control equipment, to thread the signal protocol through the train. The locomotive power supply is 230 volts, based on a 150-car train up to 12 000 feet (3658 meters) long, consuming 10 watts per car.

Additional experiments on other roads followed. But as Carlson’s team finished its first draft in 1997—“probably the best specification the AAR ever wrote,” he says—a funny thing happened: The railroads started to lose interest. At first, “they were pretty much all on board. They wanted a new system, not necessarily interchangeable with the old,” says Carlson. “And then of course, after we developed it, problems began because it wasn’t interchangeable with the old.”

You might think interchangeability wouldn’t be a problem in the United States, where today seven major carriers handle 90 percent of the industry’s business. But there are 560 railway companies in all, operating on short lines and in terminals, and most trains are still strung together and broken apart by turns. In theory, a single incompatible car could thwart an entire train’s braking system, and a single stubborn company could foil implementation across the entire network.

An eye-popping price tag for brake conversion compounds the problem. In a 2006 study commissioned by the Federal Railroad Administration (FRA), Booz Allen Hamilton estimated conversion costs at roughly US $40 000 per locomotive and an average of $4000 per freight car; converting the entire North American 2006 fleet would run to about $7.5 billion. (In 2006, the total capital investment of the seven largest railroads was $8.2 billion.)

Who would pay for the transformation, and who would reap the rewards? Hundreds of operating companies own elements of the U.S. freight car fleet, and half the fleet is owned not by railroads but by utilities and giant finance companies that lease them to shippers and railroads. Car owners, complaining that railroads will derive a disproportionate benefit from new technology, want a subsidy of some sort. Railroads, for their part, have a lot of competing needs for scarce capital investment—an AAR report released last year calls for $148 billion over 30 years for “new tracks, signals, bridges, tunnels, terminals, and service facilities.”

Saddled with a hard sell in the United States, the ECP manufacturers gamely turned their attention to other markets. In 1998 New York Air Brake outfitted a single train in Quebec’s far northeast for Quebec Cartier Mining, which hauls ore on a treacherous route down a mountain 418 km to the St. Lawrence River. Wabtec won a contract to field ECP on a mining train for Spoornet, South Africa’s national freight railway company.

In the back laboratory at Wabtec’s electronics division in Germantown, a full-scale but stationary freight train with 150 empty cars is pretending to brake. The brake pipes that normally run underneath each car arc overhead instead—2560 meters of tubing connected by regulation hoses and couplings clasped as if in a firm handshake. Beneath this skeletal canopy are the air tanks and manifolds and cylinders. From these structures rods emerge that are normally connected with brake shoes but in this case are attached to small white markers. Braking is noisy but brief.

Chuck Wolf, Wabtec’s principal systems engineer, pushes his joystick. Instantly the rods in 150 brake cylinders extend outward, and a fleet of white flags glides forward in unison. The air pounds into the cylinders in bursts, chuffing and clanging like a steam locomotive. But after 12 seconds, the noise fades away—the brakes are all set. A few moments later, Wolf releases them, and the train emits a quickly dissipating, cacophonous hiss.

Wolf applies the brakes again, this time with the equivalent of a gentle squeeze. It’s over in 3 seconds. Then he tries a somewhat firmer application. At one point a blast of air unexpectedly explodes in the room, and a flag slides back toward the cylinder. Something has gone wrong with the brakes in Car 149, so the car’s onboard computer takes them off-line. This now registers on a screen in the locomotive, which reports that 95 percent of the brakes are working.

“The operator in the cab gets much more information than he ever had before,” Wolf says. Brake data is only a beginning: The ECP cable is a platform for sensors that will one day allow the engineer to monitor other conditions, such as the status of wheels and bearings.

Lately the FRA has been lauding ECP for the safety advantages it makes possible by keeping the auxiliary reservoirs filled with air so that gradual release can be managed properly. “ECP brakes are to trains what antilock brakes are to automobiles—they provide better control,” then-administrator Joseph Boardman declared in August 2006. ECP, he added, “offers a quantum improvement in rail safety.” The electronic system reduces the distance needed to stop a train by 40 to 60 percent, and performance improves as the train grows longer and heavier.

But most in the industry expect the biggest advantage of ECP to show up as improved efficiency. That’s because there are many different ways to exploit an increase in nimbleness. You can optimize for safety, for speed, or for a little bit of each. Economic considerations will put speed at the top, for while safety is itself an economic consideration—derailments cost money—speed is the more important element.

South Africa’s Spoornet, which is converting all 6500 cars and locomotives that operate on its Richards Bay line to ECP, has reported a 9 percent reduction in round-trip travel time. When coupled with emerging signaling and dispatching technologies, faster stops will further ease congestion on crowded tracks. U.S. railroads desperately need such extra capacity: After consolidation, the industry pulled up a lot of track that seemed redundant at the time and then strained to keep up with a surge of Chinese imports. ECP is also likely to bring big savings in fuel and in maintenance of car wheels and brake shoes, which together could total at least $575 million a year.

These arguments have not yet persuaded railroads to fully embrace the technology. But the FRA makes the rules, and it can bestow its grace on an emerging technology. That’s precisely what happened in 2006, when the agency gave ECP trains operated by BNSF and Norfolk Southern a pass on time-consuming midtrip brake inspections, made largely unnecessary by the constant monitoring. “It sounds like a small thing,” says Nathan Carter, a general manager at Southern Company, an Atlanta-based utility and prominent coal shipper that conducted an expensive early ECP test that ultimately fizzled. “But when you apply it to the railroad broadly, it gives them a great deal of economic advantage”—about $125 million annually, according to Booz Allen.

In October 2007 , in the Monongahela Valley, Norfolk Southern began operating the first U.S. freight train braked exclusively by ECP. The BNSF and the Southern Company, whose flirtation with ECP a decade ago came to grief when they tried to overlay the ECP systems on conventional air brakes, now have retrofitted 260 train cars to use only ECP. That’s enough for two trains to deliver Wyoming coal to a power plant in Mississippi; the first began running the rails in January.

The earlier trials that overlaid ECP systems on conventional air brakes stumbled when carriers poached ECP equipment for traditional trains. This time around, the companies have installed stand-alone systems. “That will assure us that we will run them,” says Gerhard Thelen, a Norfolk Southern vice president.

Before this latest test began, Thelen said that his railroad would quickly expand the deployment if the tests worked out. “We basically have to replace the majority of our coal fleet”—over 20 000 cars—“in the next 10 years. If the benefits are there and the [return on investment] is there, we definitely will look towards equipping the majority” with ECP, he says. At the time, Thelen envisioned a decision as early as this year, but Norfolk Southern now says the tests will continue at least through the end of the year. And while Norfolk Southern won’t discuss preliminary results, it upped its order from New York Air Brake from 400 cars to 600 cars. The railroad now runs six ECP-equipped trains, including four over the Pocahontas Division.

Fifty years after the air brake’s invention, railroads still struggled to integrate and master it, according to Mark Aldrich, author of Death Rode the Rails: American Railroad Accidents and Safety, 1828–1965 (Johns Hopkins University Press, 2006). “The Pennsylvania Railroad—no fly-by-night operation—would routinely put men on top of cars as the trains would go down the Allegheny Valley into Altoona, and their job was to assist the air brakes with hand brakes,” Aldrich says. “They did that into the 1920s.”

ECP, however, ought to be quicker to find a place onboard the nation’s freight fleet, predicts Cliff Eby, the FRA’s former deputy and acting administrator. “We’re going to be gathering a lot of data,” he says, “and if the Booz Allen report [estimating conversion costs] is anywhere close in terms of rates of return and payback period, that data is going to be very persuasive.”

Eby argues that many more trains today run as units, with identical cars that stay coupled, as in the Norfolk Southern and BNSF coal trains. Also, it’s not impossible to mix the new system with the old. A hundred years ago, the Interstate Commerce Commission ultimately forced the integration of Westinghouse’s air brake by ordering that 85 percent of the cars in a train be controlled from the locomotive. Railroads complied by simply tacking the straggler cars to the end of the train. The notion lingers in today’s regulations: A train may continue on its way after some brakes fail en route, provided that 85 percent continue to function. In its rule making, the FRA appears to be contemplating how to apply such a provision to ECP.

In the meantime, the FRA has moved to codify the exceptions granted to BNSF and Norfolk Southern. The new rules could be in place by the end of the year. And two more of the seven largest carriers, as well as Union Pacific and Canadian Pacific Railway, were sufficiently impressed by the FRA’s flexibility to order up their own ECP tests this year. The first of two mile-long Union Pacific container trains will begin plying the rails between the Port of Los Angeles and Dallas this summer. When one of those 1600-meter-long trains wants to stop, every one of its cars will stop at the same time, and that will be a relief to everybody, starting with its engineer.

About the Author

Robb Mandelbaum, originally from Iowa, has a thing for trains. Naturally, he had to experience railroad braking for himself, so for this article he left his Brooklyn, N.Y., home for Appalachia and caught a ride with the Norfolk Southern Railway. The route is one of the first where electronically controlled braking has since been deployed. “You’d think 6 hours in a locomotive cab would wear thin after a while,” he says. “But I loved every minute of it.”