When it comes to light-emitting diodes, both inorganic and organic devices have found their niches. Inorganic LEDs, which beat organic ones hands down in brightness, energy efficiency, and durability, reign in lighting. Organic LEDs, on the other hand, can be tiny and are cheap to manufacture, so they take the prize for large-area, high-resolution and flexible applications such as displays and wearable sensors.

Researchers have now combined the best of inorganic and organic LEDs. They've made bendable inorganic LEDs by growing micrometers-tall gallium nitride rods on graphene. The tiny 50µm x 50µm LEDs glow bright blue and retain their brightness after being bent more than 1000 times. They could lead to inexpensive, high-quality displays and sensors, and could be used in touch panels and smart contact lenses, says Gyu-Chul Yi, a professor of physics at Seoul National University. Yi and his colleagues reported the LEDs in the online journal APL Materials.

Gallium nitride is a choice material for light-emitting devices. Others, including Yi’s team in the past, have made flexible LEDs by growing microstructures of the crystal on substrates such as amorphous silicon and transferring them to plastic surfaces. Researchers at the University of Illinois has made flexible devices by growing them on a rigid substrate and then using photolithography, etching, and a stamp to peel them off. Yet others have made LEDs from gallium nitride films grown on boron nitride substrates.

By comparison, Yi says his team’s new technique is simpler and could be used with various inorganic semiconductors. “[This] may lead to a range of flexible devices, including solar cells, field-emission devices, and optical communication devices,” he says. Plus, because of highly crystalline gallium nitride micro-rods grown on high-quality graphene, the new LEDs show a better combination of brightness, flexibility and mechanically strength, he says.

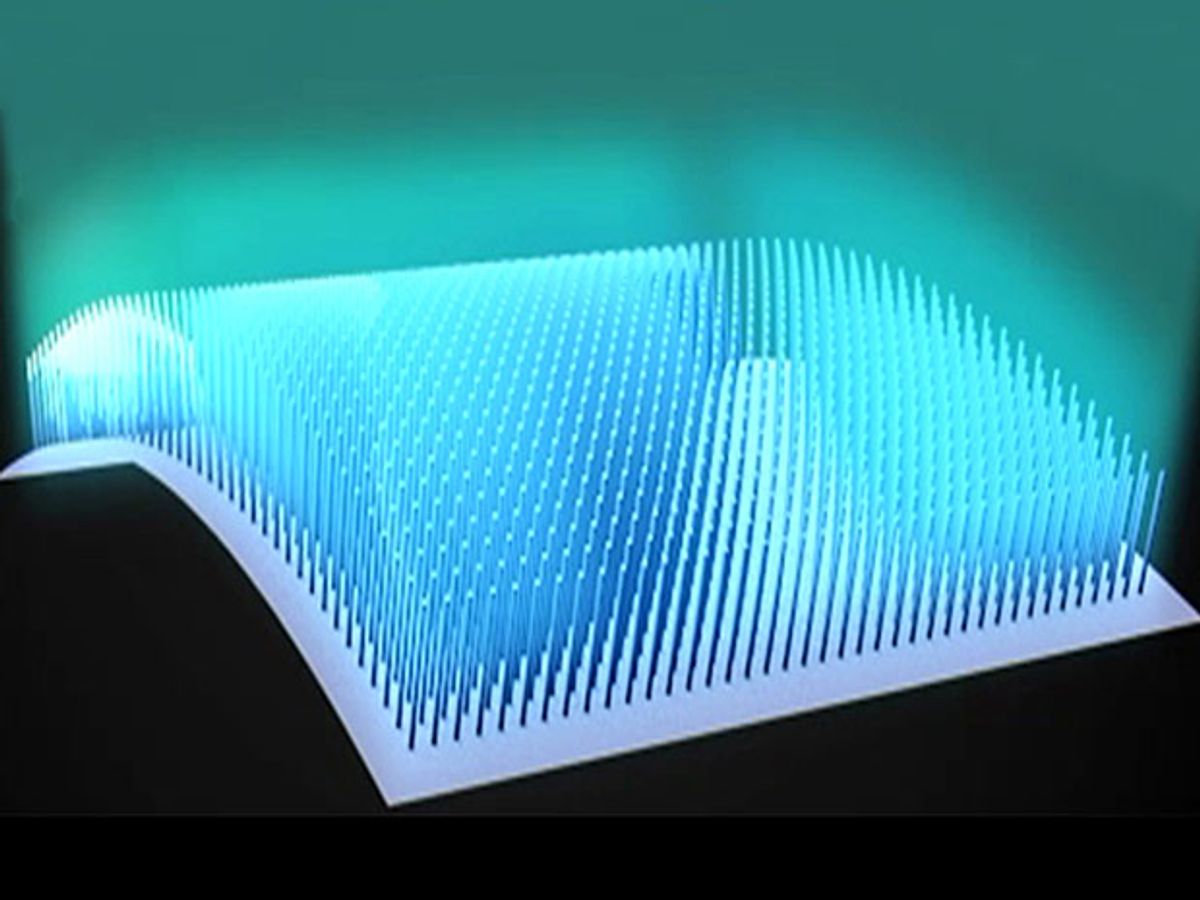

Yi and his colleagues made the LEDs by first growing a graphene film and placing it on an amorphous silicon oxide-coated silicon substrate. Then they grew a 2µm-thick layer of gallium nitride on top of it and used chemical vapor deposition to grow silicon-doped gallium nitride micro-rods on the graphene. Graphene contains carbon atoms arranged in a hexagonal pattern, and these hexagonal areas acted as sites for the growth of the gallium nitride rods. The rods were hexagonal, about 1µm thick and 7.5µm long.

The silicon-doped rods are n-type, that is, they have an excess of electrons. To make the diode’s other half, a p-type material with excess holes, the researchers coat the rods with magnesium-doped gallium nitride.

To make the devices flexible, the team etched away the amorphous silicon oxide layer on the substrate, so that they could lift off the entire graphene film along with the micro-rods. After depositing metal films on the top of the rods and the bottom of the graphene, they transferred the finished LEDs to a plastic substrate.

Highly crystalline rods that grow straight and are lined up with each other are crucial to get the right optical properties for LEDs, Yi says. Both high-quality graphene films and the 2µm-thick layer of gallium nitride underneath the rods were critical for growing vertically aligned rods, he says. Without them, the rods grew in random directions.

The new devices are nowhere close to meeting the brightness and efficiency of commercial gallium nitride LEDs or OLEDs. But Yi is confident that they could make higher-quality LEDs by finessing the metal contact layers and better controlling the micro-rods’ size, position and density.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.