Inkjet-Printed Flexible Memory Devices

New memory cells could find use in wearables and print-on-demand electronics

Flexible, inkjet-printable memory cells could help pave the way for mass-produced printable electronics, researchers from Germany and Canada say.

The new memory cells combine the strengths of the two different kinds of memory technology that have long dominated the computer industry. One type, which includes hard disks and flash memory, is relatively slow at reading and writing data but is non-volatile, meaning that it saves its data even when it gets powered down. The other, random access memory (RAM), is fast but volatile, only maintaining its data while powered.

The new memory devices are a form of resistive RAM (ReRAM), which is both fast and non-volatile. All memory cells are switchable between on and off states that represent one bit of data, a zero or one. But for ReRAM devices, these states are defined by the resistance of the memory cell, says study lead author Bernard Huber, a physicist at the Munich University of Applied Sciences in Germany.

The scientists detailed their findings online in the 4 April edition of the journal Applied Physics Letters.

In the new study, Huber and his colleagues experimented with a kind of ReRAM known as conductive bridge RAM (CBRAM). These devices each possess a simple capacitor structure, with an insulator sandwiched between two conductive electrodes. When a voltage is applied to a CBRAM cell, a conductive metallic filament forms that connects its two electrodes, resulting in a low-resistance “on” state. When the opposite voltage is applied, this conductive bridge partially dissolves, switching the cell back to a high-resistance “off” state.

Previous work sought to develop ReRAM that was printable in order to lower production costs. However, until now, all ReRAM fabricated using standard inkjet printing required additional processing steps such as electroplating or lithography, Huber says.

The scientists created their memory cells using a standard FujiFilm Dimatix DMP 2831 inkjet printer. Three different inks were used to fabricate the devices: electrically conductive silver nanoparticles; electrically insulating spin-on-glass, which can get applied as a liquid and cured to form a layer of glass; and an electrically conductive polymer known as PEDOT:PSS.

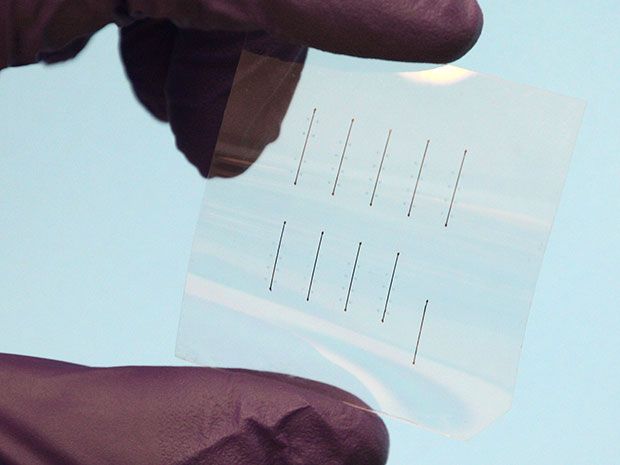

The resulting memory cells could be printed on cheap, flexible plastic foils. In addition, the researchers note they are low power consumption devices, only needing 1 micro-amp of current to write data, 0.5 volts to switch on, and -0.05 volts to switch off. Moreover, they could switch on and off at speeds of up to 300 nanoseconds (3.33 megahertz). “Our tabletop inkjet approach provides comparable device performance as otherwise obtained with full-scale clean-room processes,” Huber says.

Furthermore, each of these memory cells is potentially multi-bit. Varying the strength of the voltage applied to each device can in turn vary the size and conductance of the metallic filament that forms in each memory cell. All in all, each device could possess eight distinguishable electronic states, or three bits, the researchers say.

The size of the memory cells is limited by the resolution of the inkjet printer used; the current prototypes are about 100 by 100 micrometers large. “Any improvement in printing technology instantaneously translates into further miniaturization,” Huber says.

Potential applications for these memory cells include “the up-and-coming fields of flexible devices and wearables,” Huber says. Another possibility is print-on-demand electronics. “Imagine supermarkets printing their own smart tags; customized metro-tickets; or home appliances for which you can download the circuit design from a database to your printer," Huber says.

The researchers are now exploring combining their printed memory cells with logic circuits. They also aim to create transparent printable circuits, Huber says.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.