Bioengineers have long dreamed of creating living tissue that can be molded into everything from replacement human livers to lab-grown steaks. But a major obstacle has been keeping engineered tissues alive. Cells need a constant supply of nutrients and oxygen, and engineering a blood vessel system to deliver those nutrients and remove waste has remained elusive.

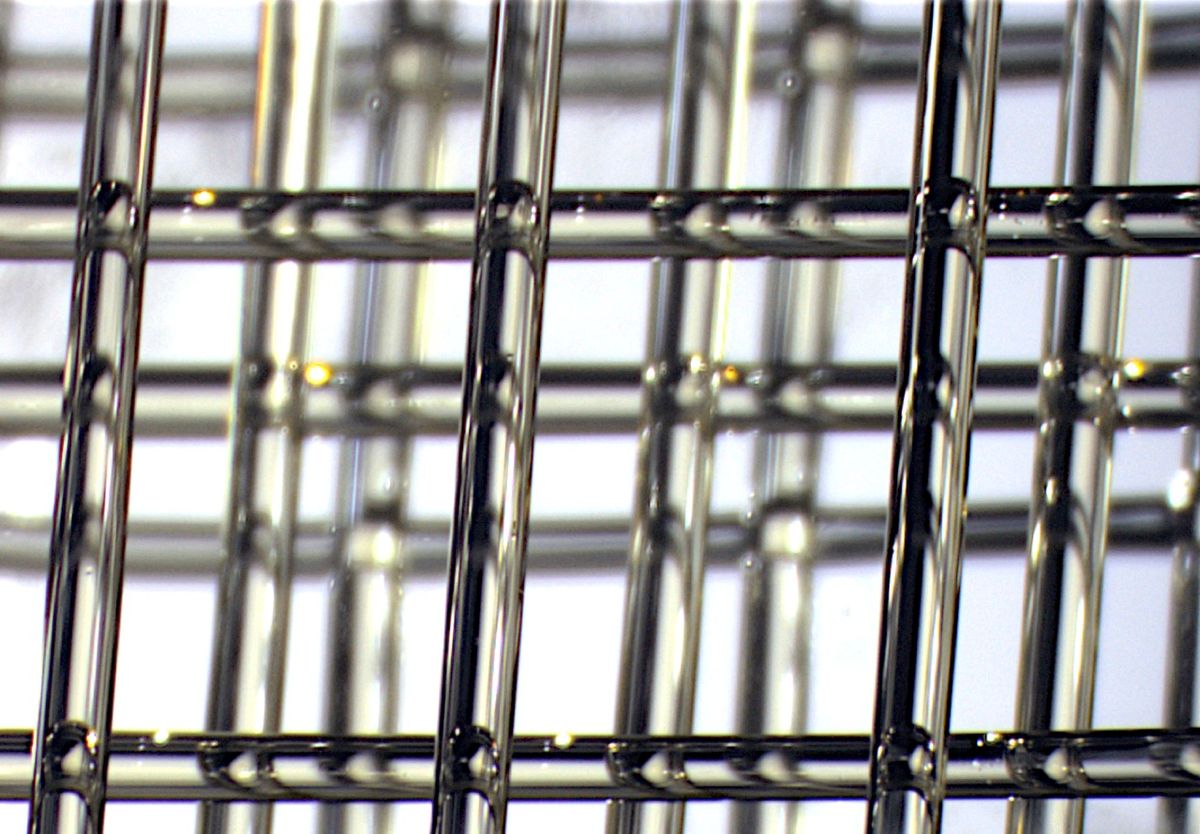

Researchers at University of Pennsylvania say they may have found a way to create vasculatures using sugar and a 3-D printer. The design starts with sucrose and glucose and, with a custom RepRap 3-D printer, the scientists were able to turn the mixture into a free-standing, three dimensional vascular template.

Jordan Miller, a postdoc at the university who co-led the research team, says he got the idea after visiting a Body Worlds exhibition, where he saw plastic casts of whole-organ blood vessels on display.

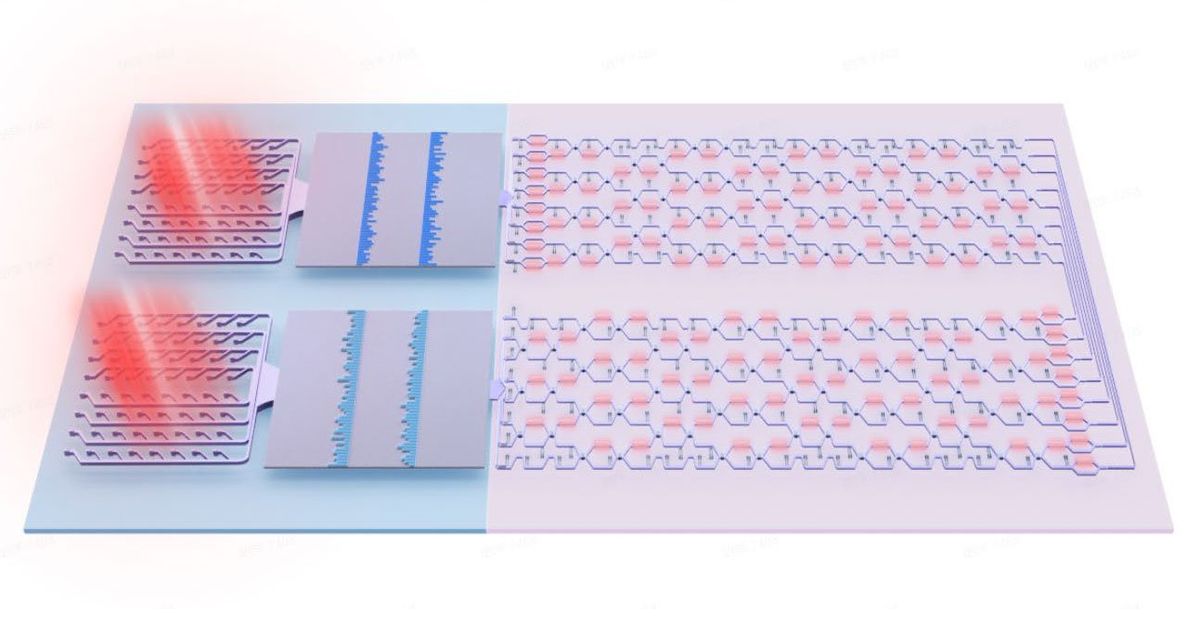

The sugar template creates a temporary set of guiding pipes where fluid will flow. After it is printed, it is coated in a thin layer of corn-based degradable polymer to help stabilize the sugar. Miller and his colleagues then pour living cells around the template to encapsulate it in what becomes solid tissue. The sugar template dissolves leaving a bare vascular network through which nutrient-rich fluid can flow. The researchers can leave the channel walls bare or seed them with cells that attach to the walls and form a lining.

Miller and professor of bioengineering Christopher Chen published their design this week in Nature Materials.

Scientists have for years been experimenting with 3-D printing and cells. The most common techniques involve layer-by-layer bioprinting where single layers of cells and gel are created and assembled one at a time. But the vasculature has remained a major challenge. Scientists have tried leaving hollow channels in the layers, but the channels have structural seams and the pressure of fluid pumping through can push the seams apart.

To get around the problem the Penn researchers turned the printing process inside out. Rather than trying to print a large volume of tissue in layers and leaving hollow channels, Chen and his colleagues printed the vasculature first—a smart idea that answers "a lot of fundamental problems in tissue engineering," according to one scientist not involved in the project.

One of the keys to the project was being able to use an open-source 3-D printer like RepRap, which can be freely modified. Several of the parts used to customize the team's RepRap were printed in plastic from another RepRap. [See the video.]

Miller says he plans to redesign the printer from scratch to focus entirely on cell biology, tissue engineering and regenerative medicine applications. Jumping on the 3-D printing bandwagon, he will teach a class on building these types of printers at a workshop this summer.

Photo credit: University of Pennsylvania

Emily Waltz is a features editor at Spectrum covering power and energy. Prior to joining the staff in January 2024, Emily spent 18 years as a freelance journalist covering biotechnology, primarily for the Nature research journals and Spectrum. Her work has also appeared in Scientific American, Discover, Outside, and the New York Times. Emily has a master's degree from Columbia University Graduate School of Journalism and an undergraduate degree from Vanderbilt University. With every word she writes, Emily strives to say something true and useful. She posts on Twitter/X @EmWaltz and her portfolio can be found on her website.