27 June 2011—A team of scientists at Stanford University has used carbon nanotubes to create nanoscale versions of two next-generation memory technologies. The results help demonstrate that alternatives to flash memory will perform well even when scaled down below 10 nanometers in size—a range where silicon memories won’t function.

Flash memory is everywhere; it is the dominant storage technology in smartphones, tablets, and cameras. But the technology is approaching its density limit: With features smaller than about 16 nm, physical limitations—like charge leakage and damage from the high voltage needed to write information—will render the devices too error prone to be useful.

To assess the alternatives, IEEE Fellow H.-S. Philip Wong, a professor at Stanford, and his colleagues constructed tiny versions of two different types of memory that are being eyed as eventual successors to flash— resistive random-access memory (RRAM) and phase-change memory (PCM). The team presented its results earlier this month at the 2011 Symposium on VLSI Technology, in Kyoto.

Like flash, both memories are nonvolatile, meaning they can retain information even when no power is being supplied to them. But the new memories promise to be far speedier and easier to miniaturize. They can also write and read smaller sets of bits than flash can, saving power in the process.

After years of research, companies are announcing their intentions to introduce PCM and RRAM technology in products in the near future. But engineers are still sorting out how well these chips will ultimately function, particularly as they are miniaturized in the coming years.

"One of the key questions is how far the technology can scale," Wong says. To investigate, his team set out to build memory cells about as small as is currently feasible, using 1.2-nm-wide nanotubes as electrodes. At that diameter, metal wires are very difficult to construct and suffer from high resistance as electrons scatter off grain boundaries and surfaces. Carbon nanotubes—rolled-up sheets of 1-atom-thick carbon—are better conductors.

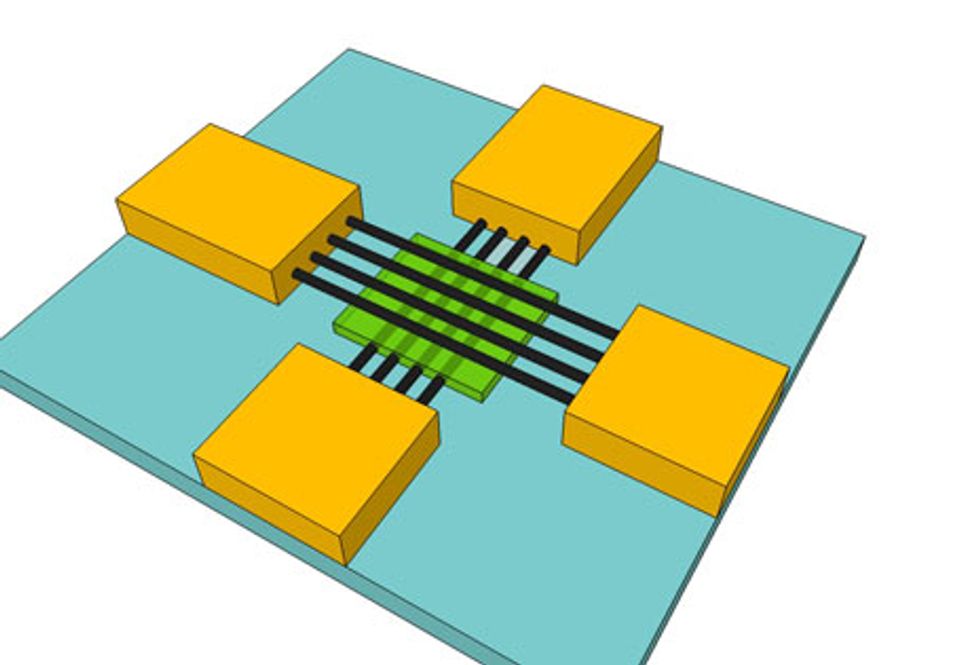

To create the new memory structures, the team grew nanotubes on quartz and then applied a 100-nm-thick layer of gold that when lifted up pulls the nanotubes with it. The gold-nanotube layer is then placed on silicon, to which it adheres. Then the gold is etched away with chemicals to leave the nanotubes on the surface.

Wong’s group used this transfer process to create a 6- by 6-nm RRAM cell consisting of two crosshatched layers of nanotubes separated by a layer of aluminum oxide. Information in the memory is changed by applying a voltage across the nanotubes that is sufficiently high to create a conductive path through the normally resistive aluminum oxide. The team was able to create a fully operational memory cell that switches with less than 10 microamperes of current and about 10 volts. That’s consistent with projections from other experiments, says Wong, and a sign that RRAM will scale well.

The team’s PCM, which was constructed using a mixture of germanium, antimony, and tellurium, also proved promising. The researchers found they could switch an estimated 2.5-square-nanometer cell of the stuff from its conductive, crystalline phase to its resistive, amorphous phase with a current of just 1.4 µA —less than one-hundredth the current used in existing PCM cells.

The current that Wong’s group used is consistent with the programming current reported by Eric Pop and his colleagues at the University of Illinois at Urbana-Champaign, who reported tests of the first carbon-nanotube-based PCM in Science in April.

"I’m excited they were able to reproduce our results," Pop says. He reckons that with further miniaturization and a change in materials engineers could cut the power consumption of PCM by another factor of 10.

Pop’s team created its nanotube memory by laying phase-change material down in a gap along a horizontal carbon nanotube. Wong and his colleagues created a vertical version of this memory, in which phase-change material is sandwiched between bottom and top electrodes. This configuration is more compact than horizontal designs, Wong says, and will allow PCM cells to be scaled down much the way flash memory is today.

One big remaining question, Pop says, is the durability of PCM, which is particularly uncertain at smaller scales. Last year, a team from IBM and Macronix—two companies with an interest in developing PCM—showed that repeated operation can damage the structure of the phase-change material around a memory cell’s electrode, limiting its lifetime.

This article was updated on 27 July 2011.