Last month, researchers at the University of Utah developed a “plastic paint” magnetic field sensor based on spintronics that looks as though it could ultimately find its way into consumer electronics.

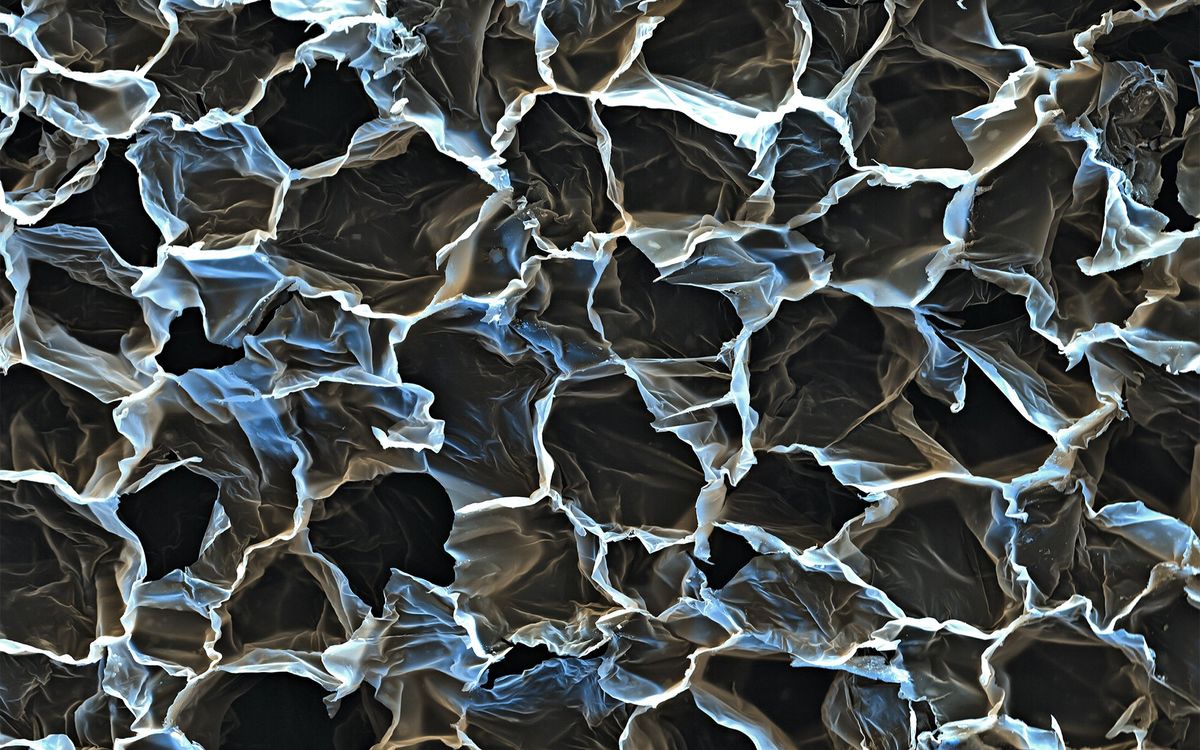

The researchers claim that the magneto-sensitive ink can be painted on just about any substrate and maintains a GMR ratio of up to 8 percent at ambient conditions. With a typical spin valve GMR ratio reaching just 5 percent for read heads inside your computer, this GMR ratio alone is pretty impressive. However, it is what the work augurs for the field of printable electronics that may have the most lasting impact.

"Our demonstrator with a magnetic switch printed on a postcard suggests that the vision of interactive fully printable electronics can become reality," Dr. Denys Makarov, leader of the group "Magnetic Nanomembranes" at the IFW Dresden, tells Nanowerk in the story covering the research.

The demonstrator Makarov refers to involved integrating the printable GMR sensor into a hybrid electronic circuit. The circuit consisted of an amplifier with a light emitting diode (LED) that had been printed on a postcard. A permanent magnet modifies the resistance of the printable magnetic sensor to switch the LED between its on/off states.

While it appears that the GMR ink can be applied by a variety of methods, such as roll-to-roll or flexography, each method demands different sized GMR flakes in the ink as well as different ink viscosity.

Makarov further notes in the Nanowerk story: “More investigations are required to understand the influence of the size of GMR flakes on the resulting GMR response of the magneto-sensitive ink. Furthermore, different binder solutions have to be tested to adjust the viscosity and conductivity of the ink."

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.