The concept of the thermophotovoltaic (TPV) device has been around for more than 50 years. In that time, its promise of a theoretical conversion efficiency of over 80 percent has been a tantalizing improvement over the still meek conversion efficiencies found in the average commercially available single-junction, silicon-based solar cells that reach just 15 percent.

Despite their theoretical promise, TPV devices haven’t been able to achieve much higher than 8 percent conversion efficiency. The problem has been that the thermal emitter (one of the two main components that make up a TPV device, the other being the photovoltaic diode) has yet to be made of a material that can withstand the temperatures required to make it effective.

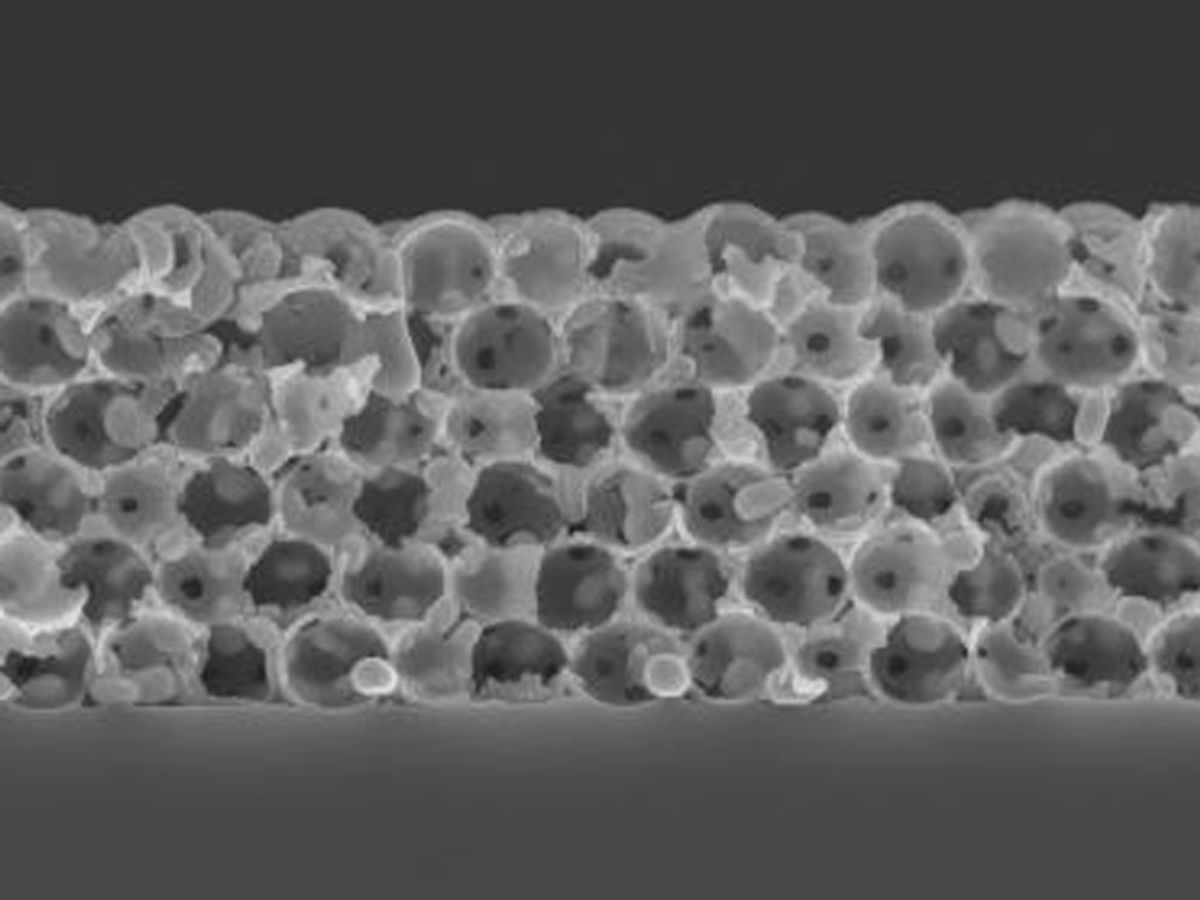

Now, in joint research at Stanford University, the University of Illinois at Urbana Champaign and North Carolina State University, researchers have discovered that if they coat the tungsten typically used in thermal emitters with a nanostructured layer of a ceramic material called hafnium dioxide that they developed, the emitter will withstand extreme temperatures.

"This is a record performance in terms of thermal stability and a major advance for the field of thermophotovoltaics," said Shanhui Fan, a professor of electrical engineering at Stanford University, in a press release.

The essential difference between a TPV and your typical photovoltaic device is the thermal emitter. In standard photovoltaics, the sun itself serves as the thermal emitter.

Unfortunately, with the sun as the thermal emitter, traditional photovoltaics can't make the most of the available energy because they are designed to take in only infrared light. All of the other, higher-energy light waves emitted from the sun are wasted as heat. The thermal emitter in a TPV device acts as an intermediary between the sun and the photovoltaic diode. It converts the higher-energy light waves into infrared light that the photovoltaic diode can convert into electricity.

"Essentially, we tailor the light to shorter wavelengths that are ideal for driving a solar cell," Fan said in the release.

While the new material the researchers developed can manage to stay stable at high temperatures, they admit that it can’t yet remain stable for the length of time that would make it viable as a component in a commercial device.

The researchers observed that when the ceramic-coated emitters were subjected to temperatures of 1000 ºC, they retained their structural integrity for more than 12 hours. At 1400 ºC, the samples began to break down after about an hour.

While 12 hours and one hour do not exactly conjure up the idea of these devices changing the photovoltaic landscape any time soon, it does open up an avenue that many had not expected was available.

"These results are unprecedented," said former Illinois graduate student Kevin Arpin, lead author of the study, in the press release. "We demonstrated for the first time that ceramics could help advance thermophotovoltaics as well other areas of research, including energy harvesting from waste heat, high-temperature catalysis, and electrochemical energy storage."

Images: Kevin Arpin

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.