The addition of nanomaterials such as graphene and carbon nanotubes to polymers and other materials in order to impart conductivity or mechanical strength is fairly commonplace at this point. It is now possible to buy a nanomaterial for a specific application and know the kind of functionalization that the nanomaterial needs, as well all the dispersion parameters required to extract the full effect of the nanomaterial’s properties in the polymer.

While the growing maturity of this value chain would seem to indicate that all is clear to start churning out materials that are either conductive or super strong or both (and in large part it is), it has still remained difficult to perform non-destructive testing of these materials during production operations such as roll-to-roll processing.

Now researchers at the U.S. National Institute of Standards and Technology (NIST) have developed a non-destructive measurement technique to ensure that nano-enabled materials are reaching their specified technical properties while being mass-produced in a roll-to-roll process.

In research described in the Nature journal Scientific Reports, the NIST researchers developed a non-contact microwave method for measuring the dielectric constant and conductivity of materials in a millisecond. You can watch a video of the device in operation below.

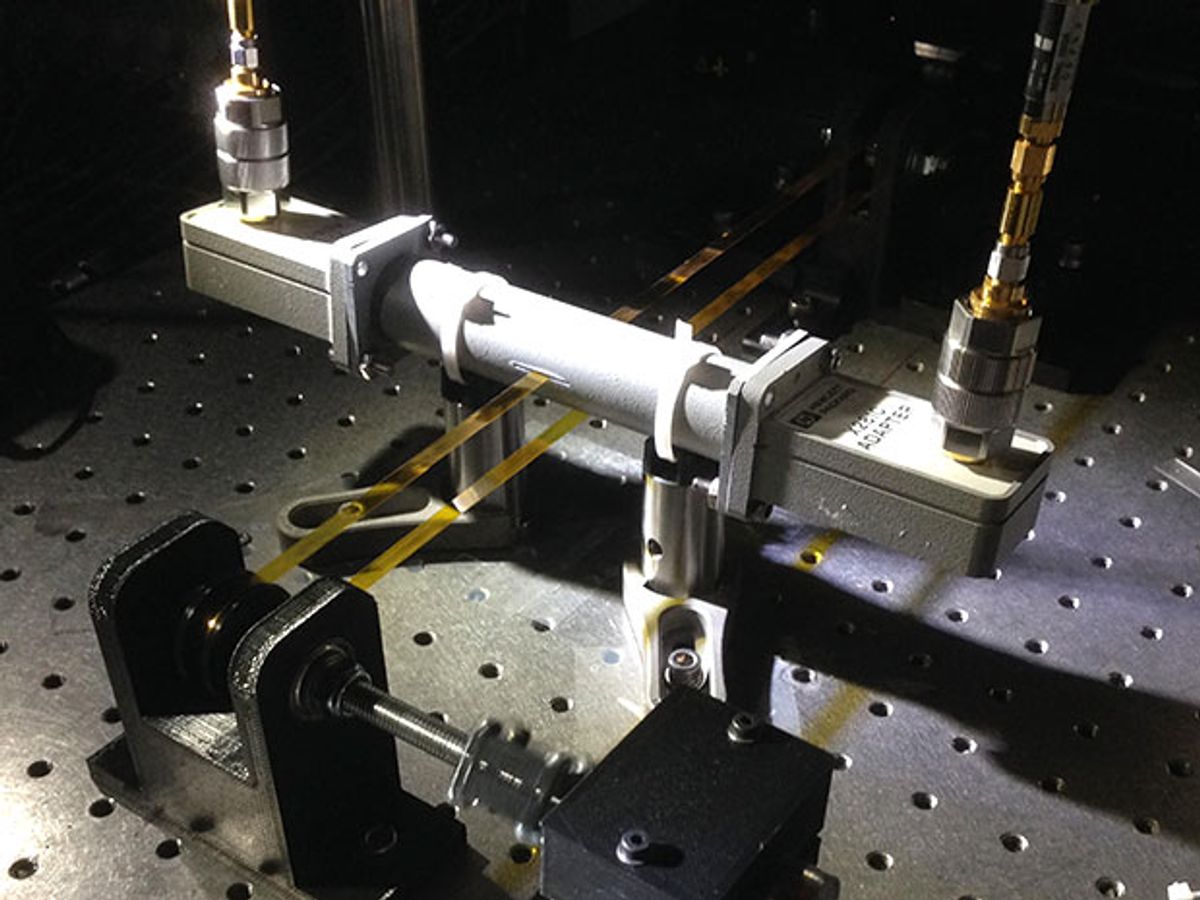

[iframe https://cdnapisec.kaltura.com/p/684682/sp/68468200/embedIframeJs/uiconf_id/31013851/partner_id/684682?iframeembed=true&playerId=kaltura_player_1456498360&entry_id=1_uh6uib1r&flashvars[streamerType]=auto allowfullscreen=true expand=1 height=315 width=620]The device works by passing the film through a metal box known as a microwave cavity, which is kind of a walled maze where electromagnetic waves get bounced around. Inside this microwave cavity, the electromagnetic waves build up to a certain resonance that depends on the box’s size and shape. When the film passes through, it changes the resonance frequency by an amount that’s mainly dependent on the film’s electrical resistance and dielectric constant, which is a measure of an object’s ability to store energy in an electric field.

The NIST researchers also fabricated a circuit that was able to measure these changes in resonance frequency. So, when the researchers passed a polyimide sheet through the microwave cavity, they could readily measure how the resonance frequency changed as the thickness of the film changed. Not only could the microwave cavity detect changes in thickness, it could also detect the parameter dubbed the “quality factor,” which, in this case, is the ratio of the energy stored in the cavity to the energy lost per frequency cycle.

Testing a material with very well known electrical properties is one thing, but this technique can also measure the electrical properties for materials that have not been well characterized, such as those using nanomaterials. The NIST researchers passed 12- and 15-centimeter-long polymer films coated with carbon nanotubes through the cavity and were able to measure the films’ electrical resistance in less than a second.

If you’re a thin-film manufacturer using nanomaterials in the material matrix, the advantages of this system are pretty clear.

“You can measure the entire thing, not just a small sample,” said NIST physicist, Nathan Orloff, in a press release. Orloff’s colleague, Christian Long, added: “This method could significantly boost prospects of not making a faulty batch in the first place.”

The technology has been patented and the NIST researchers say they are already receiving inquiries from industry.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.