Aerogels have long been one of those ‘gee whiz’ materials that gets people to take notice—watching a solid float on air tends to do that. To accomplish their remarkable feats, aerogels are essentially a gel in which the liquid component of the gel has been replaced with gas. We’ve seen them used in applications from “invisibility cloaks” to oil spill remediation.

Now researchers at Lawrence Livermore National Laboratory (LLNL) have produced an aerogel out of graphene that could have applications ranging from electronics to energy storage. Boosting the ‘gee whiz’ factor: the new material is produced through 3-D printing.

In research published in Nature Communications, the LLNL research team were able to produce a predetermined architecture for a graphene-based aerogel, which previously had always been random, by using 3-D printing. By being able to define the architecture, the researchers were able to improve the material’s performance.

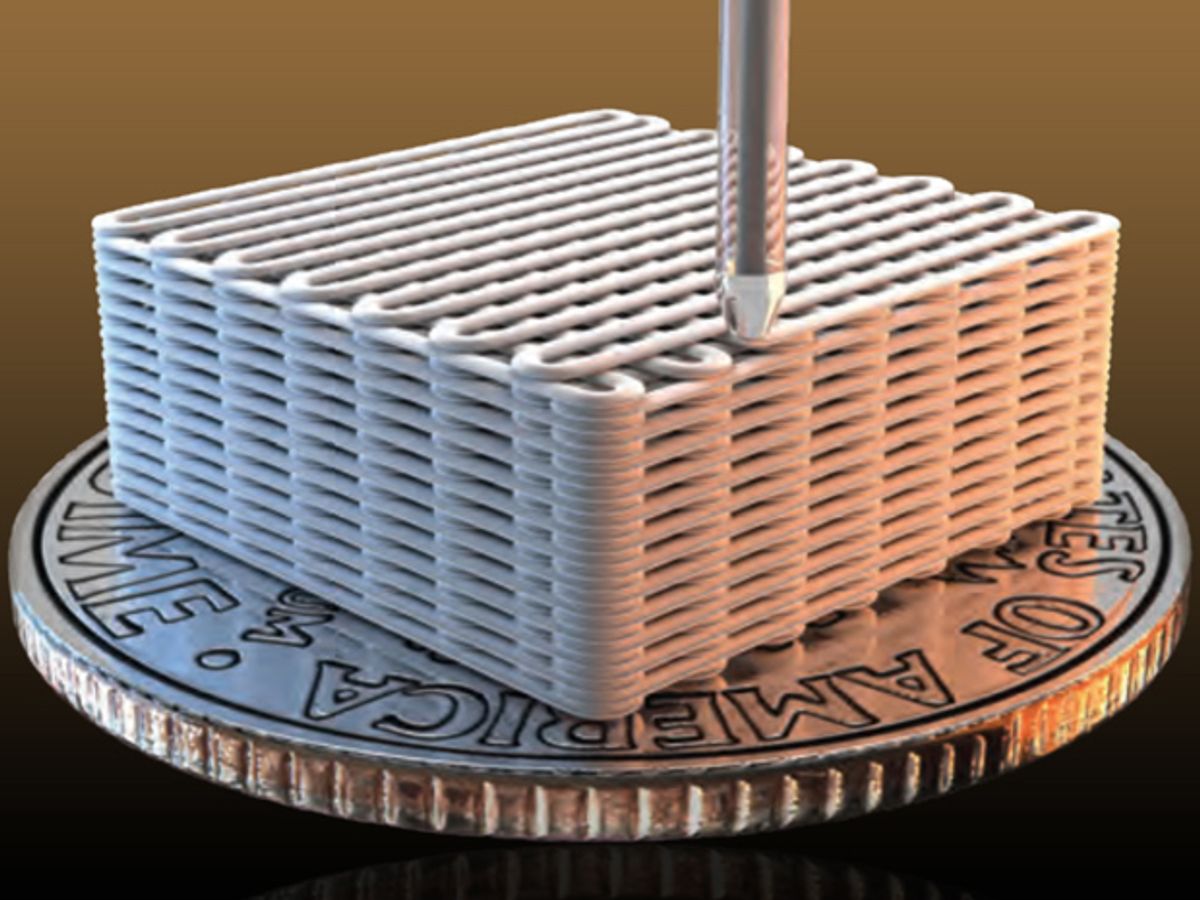

The 3-D printing process used for fabricating these aeorgels is called direct ink writing. In the process, graphene oxide (GO) inks are combined with an aqueous GO suspension and a silica filler to create the ink. This ink is then extruded through a micronozzle to layer up the structure. The final structure is then put into hydrofluoric acid where the silica is burned off. You can see this process in the video below:

“Making graphene aerogels with tailored macro-architectures for specific applications with a controllable and scalable assembly method remains a significant challenge that we were able to tackle,” said engineer Marcus Worsley, a co-author of the paper, in a press release. “3D printing allows one to intelligently design the pore structure of the aerogel, permitting control over mass transport (aerogels typically require high pressure gradients to drive mass transport through them due to small, tortuous pore structure) and optimization of physical properties, such as stiffness. This development should open up the design space for using aerogels in novel and creative applications.”

The researchers believe that being able to tailor the architecture of the aerogels will open up the possibility of using them in applications that they were excluded from previously, such as pressure sensors and flow batteries.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.