Researchers at Cornell University, in Ithaca, N.Y., may have found a way to bring the long-moribund prospects of rechargeable lithium-metal batteries back from the dead with a novel nanostructured membrane that could make the batteries both safe and efficient.

In research described in the journal Nature Communications, the Cornell researchers looked anew at the problem that has been plaguing the prospects of rechargeable lithium-metal batteries: growths, referred to as dendrites, that over time branch out of the anode, into the electrolyte, and eventually expand to the point where they actually bridge the gap between the two electrodes and cause the battery to short out—or even worse.

This phenomenon has been extremely frustrating because lithium metal in the anodes of rechargeable batteries has been described as the holy grail material in lithium-based batteries. Its substantial benefits include tremendous specific capacity. A Li-metal anode battery’s capacity could be as high as 3,860 milliampere-hours per gram, whereas a typical Li-ion battery with graphite on the anode tops out at around 380 mAh/g.

As tantalizing as that performance may seem, lithium-metal batteries can create some pretty scary situations in operation. Some may recall the rechargeable lithium-metal batteries marketed by Moli Energy back in 1989. Long story short, they caught on fire, leading to the bankruptcy of the company. The problem was the same issue mentioned earlier: the lithium metal growing dendrites from the anodes into the electrolyte, leading to thermal runaway conditions and fires.

There has been a quasi solution to this problem that involves placing a ceramic-based membrane between the two electrodes so that the dendrites are prevented from extending so far as to bridge the gap between the two electrodes. However, the ceramic also degrades the battery’s performance.

“The problem with ceramics is that this brute-force solution compromises conductivity,” said Lynden Archer, who led the Cornell research, in a press release. “This means that batteries that use ceramics must be operated at very high temperatures—300 to 400 degrees Celsius (572 to 752 °F), in some cases. And the obvious challenge that brings is, how do I put that in my iPhone?”

To make rechargeable lithium metal batteries a possibility for mobile devices, the researchers created a membrane by grafting polyethylene oxide (PEO) onto silica, creating so-called “hairy” nanoparticles. The resulting material, called nanoscale organic hybrid material (NOHM), is something that Archer has been investigating for use as a membrane material for years.

Archer and his team took the PEO and cross-linked it with the polymer polypropylene oxide to create a membrane that is both strong and compatible with the function of the electrolyte.

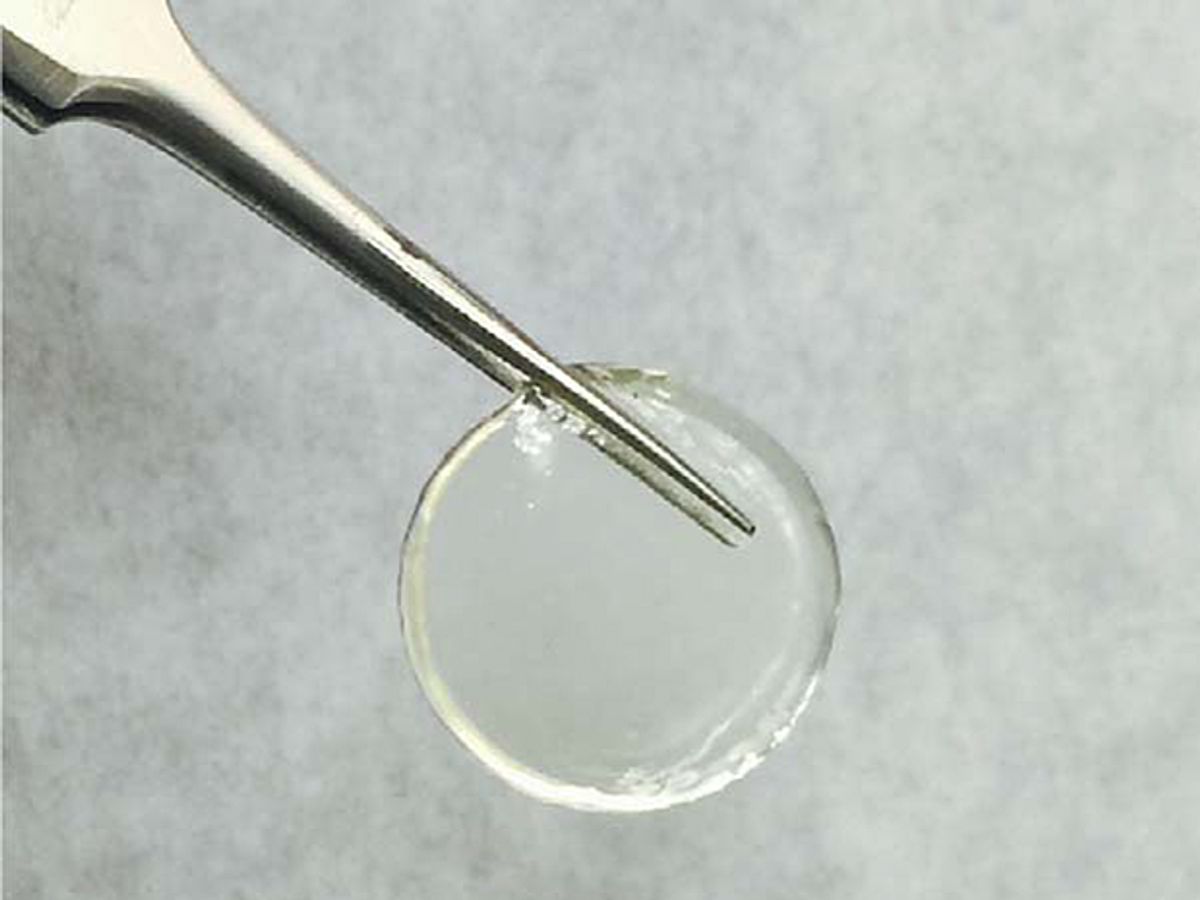

“Instead of a ‘wall’ to block the dendrites’ proliferation, the membranes provided a porous media through which the ions pass, with the pore-gaps being small enough to restrict dendrite penetration,” said Snehashis Choudhury, who propsed the nanomembrane, in a press release. “With this nanostructured electrolyte, we have created materials with good mechanical strength and good ionic conductivity at room temperature.”

According to the researchers, the resulting nanomembrane yields the best-ever performance for a lithium-metal battery featuring a membrane introduced to halt dendrite growth. While performance figures are promising, the researchers say that the biggest benefit might be the fact that it’s a solution that doesn’t require much change in the battery manufacturing process.

Choudhury added: “The membrane can be incorporated with batteries in a variety of form factors, since it’s like a paint—and we can paint the surface of electrodes of any shape.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.