Researchers at IBM’s T. J. Watson Research Center have developed a technique for achieving greater control over the self-assembly of nanowires. The team claims that the nanowires fabricated in this way can be tuned to have properties that would make them attractive for a new generation of transistors.

To accomplish this, the IBM researchers have combined so-called top-down manufacturing techniques—like lithography—with bottom-up techniques that “grow” electronics through self-assembly to create a single approach that produces nanowires with specific electrical properties. Having control over the properties of nanowires makes it possible to better target them for various devices, like single-electron transistors.

The top-down process of lithography has been the basis of electronics manufacturing for sixty years, going back to the 1950s. Despite noble efforts that have brought the scale of this type of manufacturing down to 7 nanometers, the end is nigh for this approach. Some experts don’t see how top-down processes can go much below 3nm and still lend themselves to mass production scales.

The hope has been that so-called bottom-up manufacturing techniques, where the basic elements of electronics are grown rather than etched away, would help achieve smaller scales and still scale up to mass production.

The problem has been that self-assembly is primarily controlled by the limits of physics. In large part, you have to take what you get with just a little guidance thrown in. What you would want is a self-assembly process that gave you the kind of control over patterning that is enjoyed in top-down processes like traditional lithography.

In work described in the journal Nature, the IBM researchers achieved this combination of self-assembly and imposed patterning by using catalytic particles. In the video below, you can see how a silicon nanowire grows from a gold-based catalyst. The reaction occurring in the video is taking place at 500 degrees Celsius and is sped up 30 times.

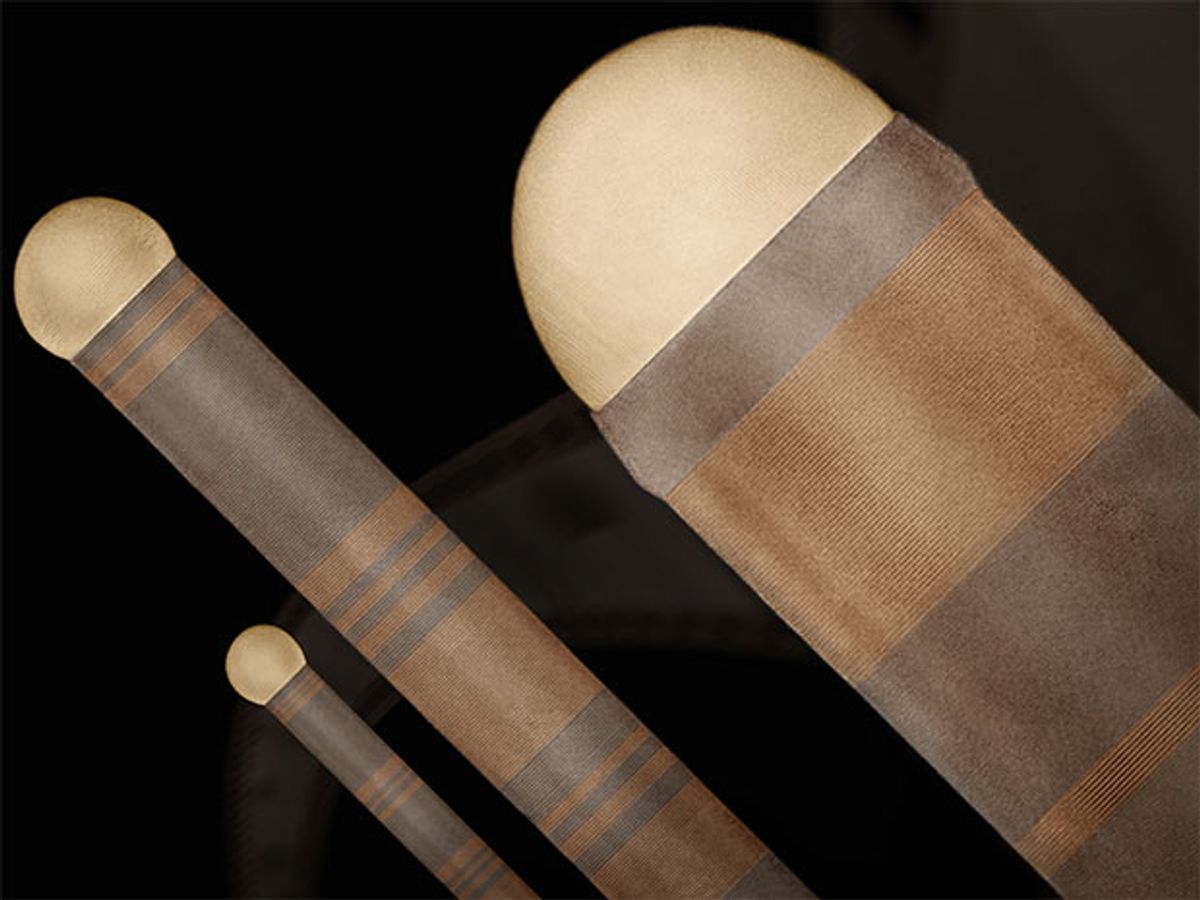

The IBM researchers are particularly interested in producing gallium arsenide nanowires. In this case, the nanowires are grown by using the reactive gases trimethylgallium and arsine as the source for the gallium and arsenic. When the gold nanoparticle catalysts are introduced, they spur a reaction with the gallium, which transforms the gold nanoparticles into hemispherical liquid gold-gallium droplets. Then these newly formed droplets combine with the gallium and arsenic to create a gallium arsenide nanowire.

Growing these nanowires this way changes how the gallium and arsenic atoms are piled on top of each other in the nanowire. With two possible options for how the atoms are arranged, this technique makes it possible to switch between these two options simply by changing the temperature of the reaction or changing the ratio of the feeder gases. By changing this stacking arrangement of the atoms, the electrical properties of the nanowires can be specified.

The IBM researchers believe that this ability to directly control how nanowires self-assemble will inspire other researchers to consider new electronic devices based on these configurable nanowires.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.