The story of nanomaterials in textiles dates back at least to the formation of the National Nanotechnology Initiative (NNI) at the beginning of the 21st Century, when Nanotex was the NNI’s poster company for the new exciting world of nanotechnology.

The role of nanomaterials in textiles has evolved since then from comparatively simple hydrophobic materials that Nanotex continues to produce to where we now are creating textile electrodes using graphene or weaving nanowires into t-shirts to make them into supercapacitors.

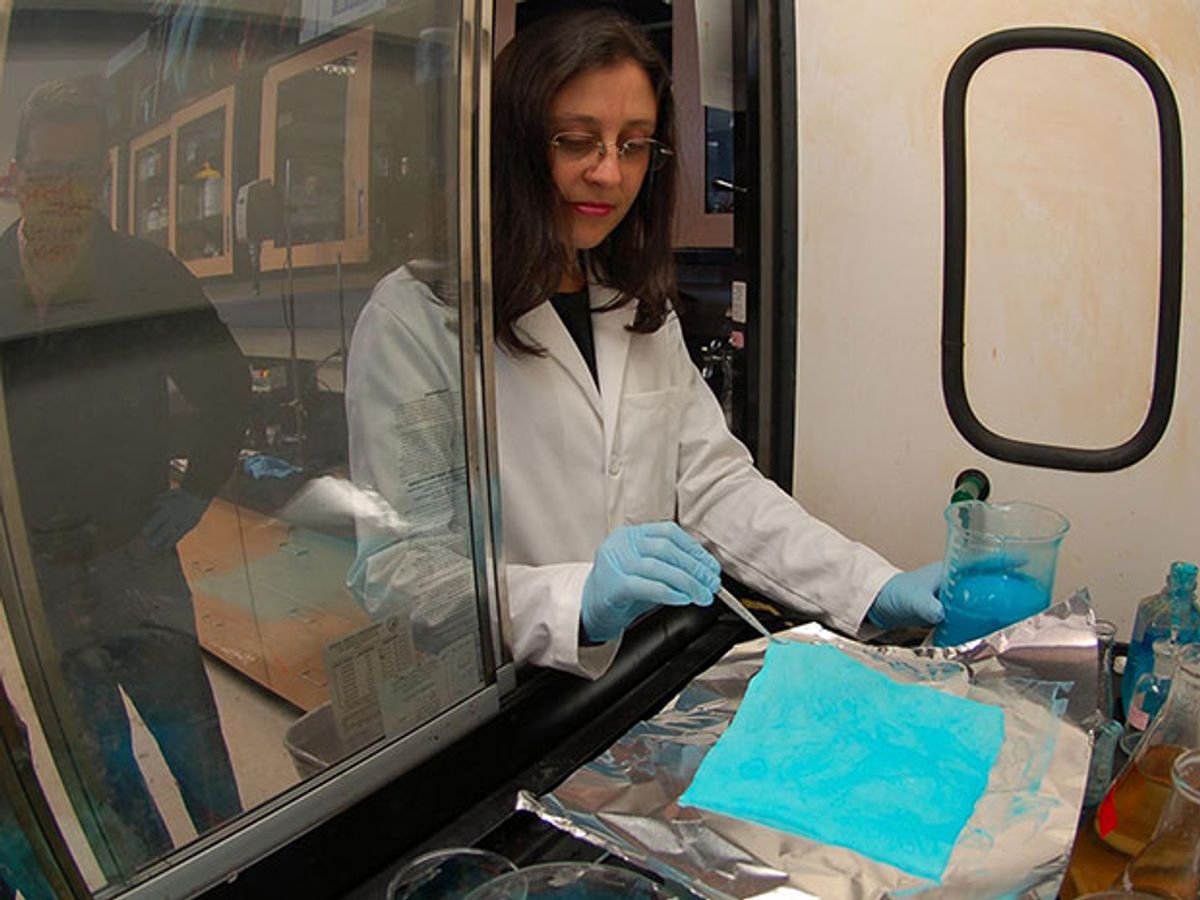

Perhaps the greatest metric of how far nanomaterials have come in textiles is the range of work being done by students at Cornell University where they are using a variety of different nanomaterials in combination with cotton to create clothing that kills bacteria, conducts electricity, and serves as a platform for electronic devices.

“Cotton is one of the most fascinating—and misunderstood materials,” said Juan Hinestroza, associate professor of fiber science, who directs the Textiles Nanotechnology Laboratory at Cornell, in a press release. “In a nanoscale world—and that is our world—we can control cellulose-based materials one atom at a time.”

The basis of much of the work Hinestroza and his students are doing is exploiting the irregular topography of cotton and adding different nanomaterials to it to produce attractive properties.

One Cornell student added conformal coatings of gold nanoparticles along with semiconducting and conducting polymers to create a dress that was capable of charging a mobile phone. The dress used photovoltaic material as trim and a USB charger that was placed in the waist.

In another design, some of the students used metal organic framework molecules (MOFs), which are nanoporous materials that have a large number of microscopic channels, to create a textile that wards off insects, particularly mosquitoes. The students filled the microchannels of the MOFs with an insecticide that doesn’t wear off like the kind of insecticide we apply to our skins.

“We want to transform traditional natural fibers into true engineering materials that are multifunctional and that can be customized to any demand,” said Hinestroza in the release. “We are chemists, we are material scientists, we are designers, we want to create materials that will perform many functions, yet remain as flexible and as comfortable as a t-shirt or an old pair of jeans.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.