While nanotechnology gets a lot of attention for enabling news types of energy generation, such as photovoltaics, or ushering in a new energy storage technology, it may in fact be in the mundane role of energy savings and efficiency where it may hold the most promise.

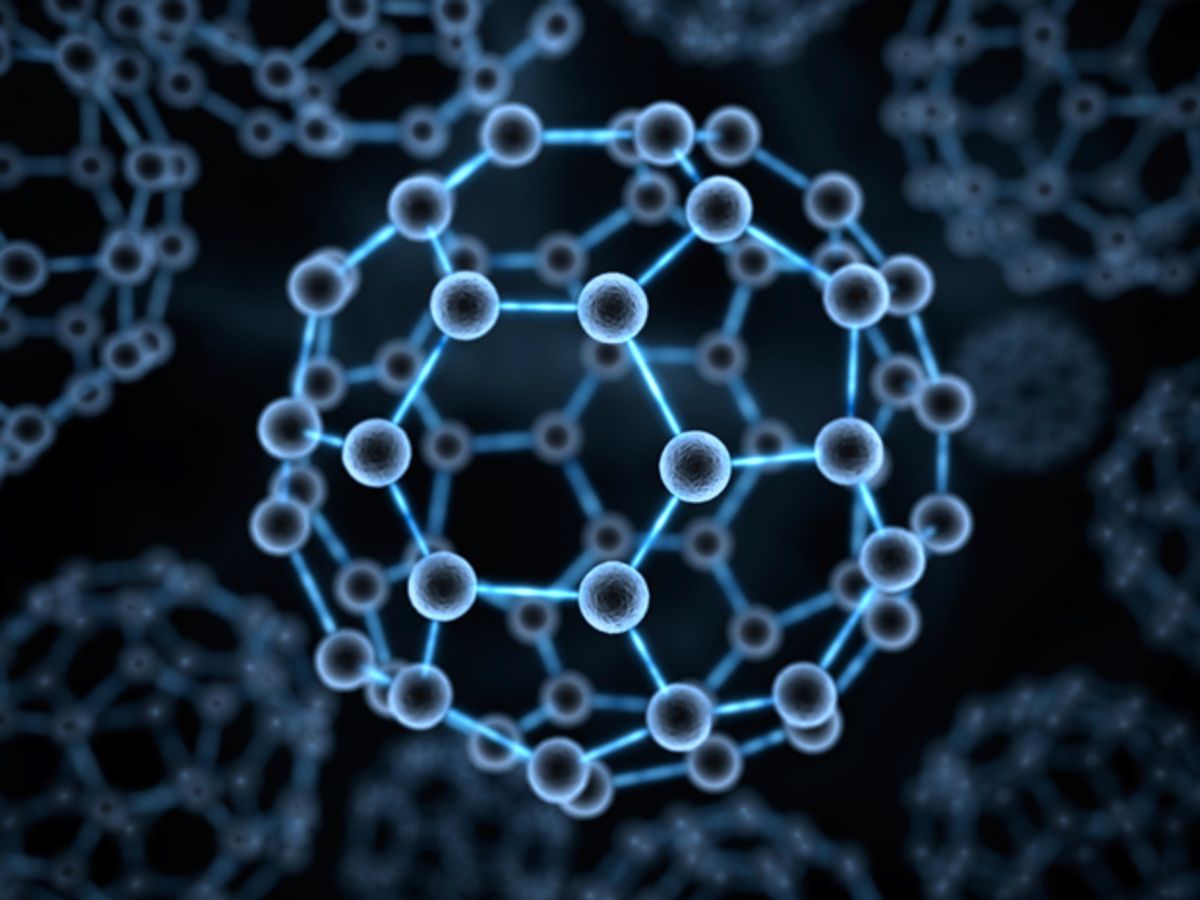

Along these lines, researchers at the Chalmers University of Technology in Sweden have demonstrated that the addition of carbon nanoballs (also known as C60, Buckyballs, and fullerenes) into the plastic insulation used in high-voltage lines enable the cables handle up to 26 percent more voltage than standard cables.

This development holds particular promise as we become increasingly dependent on alternative energy sources, such as wind turbines out at sea, where the source of the energy has to travel significant distances before it makes it way to the grid.

"Reducing energy losses during electric power transmission is one of the most important factors for the energy systems of the future," said Chalmers researcher Christian Müller, in a press release.

In research published in the journal Advanced Materials, the Chalmers team and Sweden-based chemical company Borealis found that variants of the C60 carbon ball, a nanomaterial in the fullerene molecular group, protect against the breakdown of the insulation plastic used in high-voltage cables. It only takes a small amount of the carbon balls to improve the plastic insulator’s voltage capacity by 26 percent, according to the researchers.

Of course, experts have known for forty years that additives to the insulator can improve voltage capacity. However, there remained doubt as to what kind of materials to add and how much of it would be needed. So, no additives are currently used in the manufacturing of the insulating material and they must be made to the highest possible level of chemical purity.

"A major issue in the industry is how transmission efficiency can be improved without making the power cables thicker, since they are already very heavy and difficult to handle," said Müller in the release.

This research has demonstrated that to date fullerenes are the best voltage stabilizers identified for insulation plastic. This capability is the result of fullerene’s ability to capture electrons that would otherwise destroy surrounding molecules.

The next step in the research will involve ramping up from laboratory experiments to testing the method in complete high-voltage AC cables. High-voltage direct current cables will be tested as well, because they are better than AC for transmitting power over long distances.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.