Standard lithium-ion batteries, like the ones in everything from your cell phone to your plug-in electric vehicle, have electrodes that contain intercalation compounds. They are capable of charging and discharging without substantial change in volume or structure, but are limited with regard to energy density. Recently, much work has been done on battery materials with significantly higher energy densities, but these materials typically degrade extremely quickly. Now, for the first time, researchers have found a way to see clearly what is really happening inside the electrodes that leads to that short lifespan, potentially opening a way to engineer our way around the problem. They published a study Thursday in the journal Science.

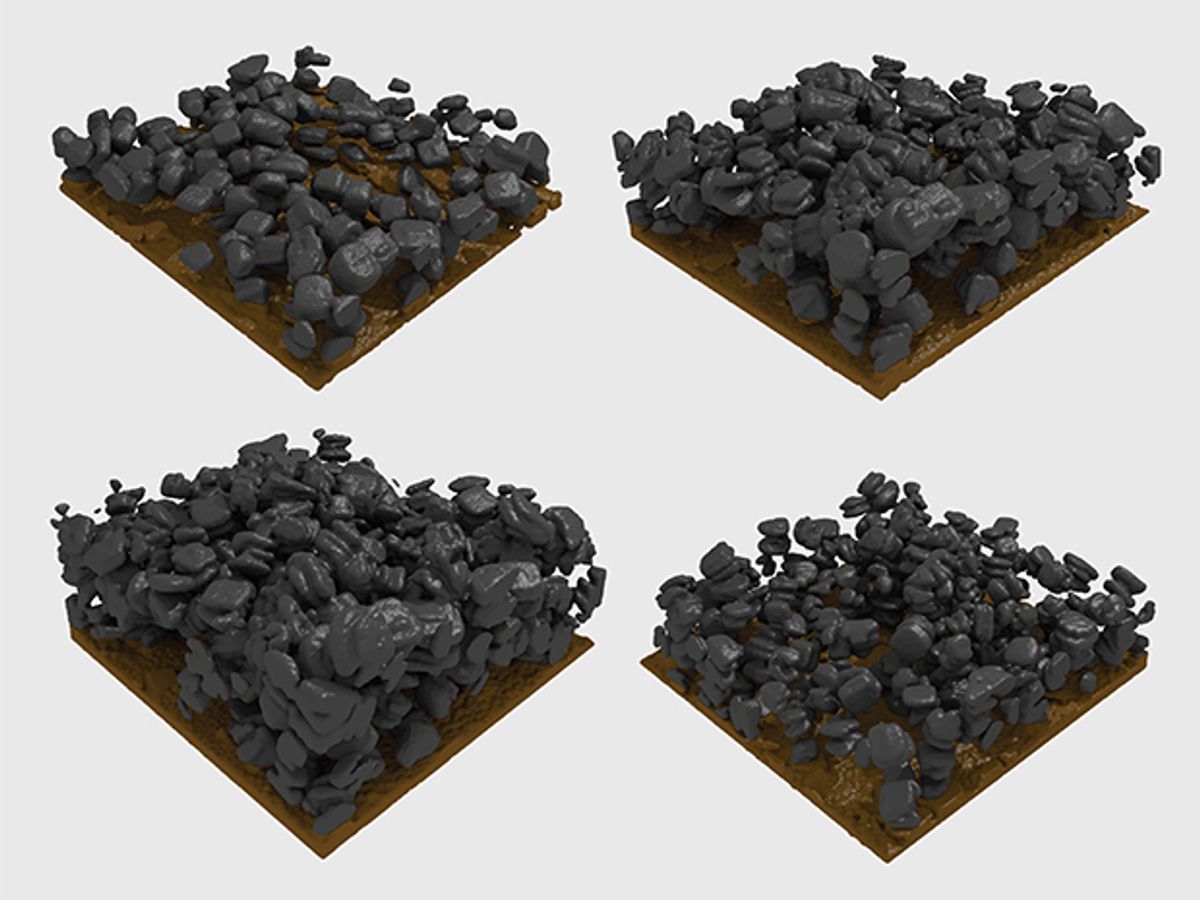

Using the tomographic x-ray microscopy beam (TOMCAT) at the Swiss Light Source, researchers showed that a tin-oxide electrode expands during charging thanks to an influx of lithium ions. That influx-induced increase in volume turns out to cause irreversible damage by forming cracks within the electrode particles. Martin Ebner, one of the study authors and a PhD student at ETH Zurich, said in a press release that the crack formation is not random; the cracks form at spots where defects already exist. During discharge, the tomography imaging showed that the volume does decrease, but the cracks prevent the electrode from returning to its initial state. The image above shows the tin oxide particles undergoing such structural deformation during charge and discharge.

Specifically, the electrode they measured started life at 50 micrometers, and expanded more than 100 percent to 120 µm during charging; it then shrank back to only 80 µm. The average particle volume fraction, meanwhile, decreased back to a level below where it started, which the authors write implies the polymer binding the particles and the conductive matrix are distorted after just the one charge. "This distortion of the conductive matrix, together with particle fracture, is known to electrically disconnect particles from the rest of the electrode leading to capacity loss," they write.

Importantly, this technique could be repeated using other materials, potentially leading the way to better batteries in general. "Visualizing batteries in operation was essentially impossible until recent advances in x-ray tomography," said senior author Vanessa Wood, also of ETH Zurich. The researchers conclude that "the type of quantitative three-dimensional, and time-resolved images of particle lithiation introduced in this work will provide the experimental data necessary to comprehend the complex electrochemical and mechanical interactions in silicon and related materials."

Photo: Martin Ebner/ETH Zurich

Dave Levitan is the science writer for FactCheck.org, where he investigates the false and misleading claims about science that U.S. politicians occasionally make.