Betting on Algal Biofuels

Algae could make the perfect renewable fuel

Most people consider algae a nuisance. But it turns out that one man’s pond scum is another man’s gold, to draw on an old expression. An algal species with the right properties could be immensely valuable. That’s why we and others at the National Renewable Energy Laboratory, in Golden, Colo., have been busy “bioprospecting” for promising scoops of slime.

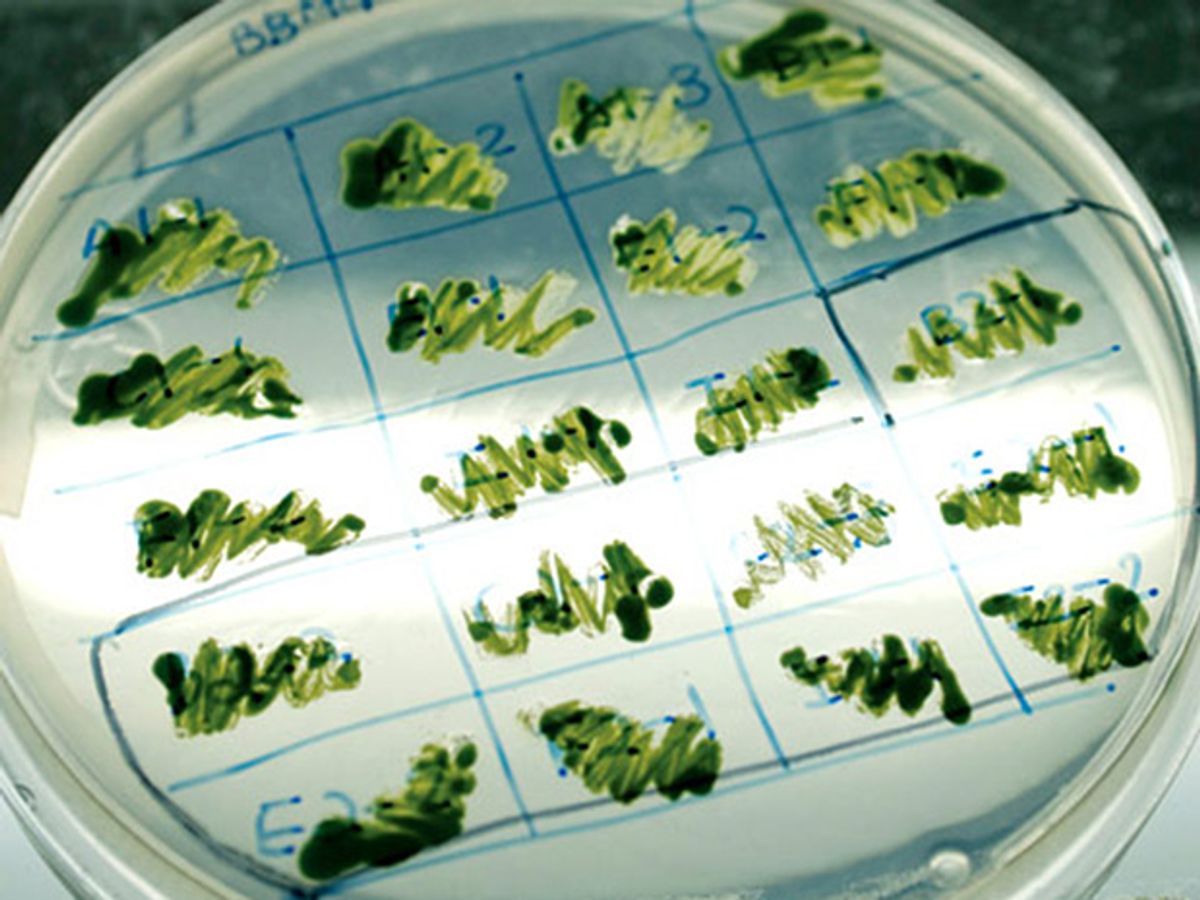

Recently, we dispatched a graduate student to pan for algae in a nearby creek, in Utah’s Great Salt Lake, and in other spots where we hoped to find organisms thriving in extremes of temperature, pH, and sun exposure. We’re hunting for novel strains that can grow quickly and efficiently enough to provide a renewable source for diesel, gasoline, and jet fuel, which would help reduce the world’s dependence on fossil fuels while slowing the buildup of carbon dioxide in the atmosphere.

What kind of algae could do all that? Right now, that’s an unanswered question. Algae are microscopic organisms, which, like plants, use photosynthesis to convert light into chemical energy while at the same time absorbing carbon dioxide from the atmosphere. Algae turn the carbon they take in first into sugars and then into oil, which can be made into fuel. But some strains produce much more oil than others.

Our recent bioprospecting ventures have unearthed hundreds of different algae types. There are also about 30 000 known species to consider. We want to figure out which of them could thrive on polluted or salty water, reproduce rapidly, and of course, make copious amounts of oil. Luckily, we can go through them pretty quickly, using a microscope, a few other specialized instruments, and a dye that fluoresces when it contacts oil. Several strains we examined recently exploded in glowing green halos when we tested them in this way.

The simple elegance of these microscopic oil factories has motivated a hundred or so start-ups to try to tackle algal biofuel production. Major oil companies, including Chevron, ConocoPhillips, ExxonMobil, and Royal Dutch Shell, are studying this idea. Several airlines have even performed test flights using fuel blends consisting of a petroleum-based fuel, algal oil, and oils from more traditional biofuel crops, such as Jatropha, a genus of succulent plant that produces oil-rich seeds.

If you can make biofuel with jatropha or other vegetable crops, why consider algae? In short, because they grow much faster and produce more oil than terrestrial plants. A glance at the mossy film on the surface of virtually any pond will confirm that the needs of these organisms are truly humble. Like houseplants, algae require water, sunlight, a few nutrients, and carbon dioxide from the air. They grow prolifically and accumulate large amounts of oil when they experience environmental stress.

That algae produce oil isn’t a great surprise. The fossil fuels that run our cars likely came from ancient algal cells that dropped to the bottom of former oceans and were covered by sediment. Algae use their oil the same way animals use body fat, as a source of energy when times are lean. For animals, lean times come between feedings; for algae, this happens every night, when there isn’t any light to power photosynthesis.

Oil production also helps algae overcome the stress of growing in full sunlight, which can be hard on these cells, particularly when they are starved of one or more nutrients. Such deprived algae tend to generate highly reactive chemicals called free radicals, which can cause molecular havoc within. The conversion of CO2 to oil prevents the buildup of free radicals, helping the cells avoid internal damage. This oil is very similar to the vegetable oil you might buy at the grocery store.

But unlike corn or olives or soybeans, which can be harvested only once a season, algae grow rapidly enough to be reaped continuously. They also have a higher oil content—some as high as 50 percent. A hectare of soybeans, for example, typically produces only about 500 liters of oil each year, whereas a hectare of algae growing in a shallow pond can easily generate 9000 L of oil—and perhaps as much as 47 000 L—annually. That makes algae many times as productive as oil palms, the most oil-rich source of biodiesel now in use. (The expanding cultivation of oil palms is problematic, however, as they are responsible for much of the deforestation across Southeast Asia.)

For making the most oil in the least amount of space, algae win hands down. But there are other reasons to believe they provide the most promising source for biofuel. To understand why, you need to take a closer look at the competition.

Algae can also grow in large tanks called fermentors, similar to the stainless steel tanks used to produce ethanol. But for algae you need to add sugars, because the steel walls of the tanks block light, preventing photosynthesis. As a result, algae grown in fermentors do not produce their own sugars and do not capture CO 2, giving such biofuels the same disadvantages as corn ethanol.

The leading alternative fuel today—no surprise here—is ethanol, which can be used either as an octane-enhancing additive, cutting down on carbon monoxide and other smog-causing emissions, or (in suitably equipped vehicles) in much higher concentrations. “Flex-fuel” vehicles in the United States, for example, can burn E85, a blend of 85 percent ethanol and 15 percent gasoline. Ethanol now accounts for about 6 percent of the global consumption of what’s normally just labeled “gasoline.”

Today the fuel is made almost entirely from corn kernels or sugarcane, but scientists are also pursuing ethanol made from lignocellulose, the fibrous material that makes up the bulk of most plant matter. Plentiful sources of such biomass include the by-products from agriculture, forestry, and the food-processing industry. Switchgrass and Miscanthus grasses grown specifically for ethanol production on nonagricultural lands are also expected to add significant amounts of biomass for ethanol production in coming years.

Although these emerging sources are not yet producing much, the U.S. Energy Independence and Security Act of 2007 calls for the production of 136 billion L of renewable biofuels by 2022. Another regulation caps the amount of corn-based ethanol at 57 billion L and requires that at least 61 billion L of the remaining biofuel allotment come from lignocellulose.

Whether this can be done in an economic and environmentally responsible manner is open to debate. We’ll almost certainly continue to use ethanol as a transportation fuel, but it has its disadvantages. For one thing, it makes for hard starting in cold weather. Also, its energy density is considerably lower than that of gasoline or diesel. The energy content of biodiesel, on the other hand, is nearly equivalent to that of petroleum diesel.

Biodiesel is usually made by combining methanol and lye with vegetable oil, animal fat, or recycled cooking grease. It can be blended with ordinary diesel to reduce vehicle emissions or used in its pure form. And it can even be transformed into a kerosene-like jet fuel. Unfortunately, the world doesn’t currently have enough vegetable oil or old grease to make sizable quantities of biodiesel. Even if the United States were to devote its entire annual crop of soybeans to producing biodiesel, it would barely make a dent. But no nation would ever do that, because food production is still the No. 1 use for soybean oil. Algae, on the other hand, need not present such a conflict. Here’s how we’d like to see them put to work.

You can cultivate algae in three ways, the easiest of which employs shallow ponds with paddle wheels that constantly mix the water. Large tracts of desert might be the ideal place to grow algae as long as enough water and the proper nutrients can be secured. Such cultivation is practiced in several areas of the world, including the United States, Australia, New Zealand, Israel, China, and parts of Europe, mostly using otherwise undesirable land and saline water or brackish groundwater.

But algae have another neat attribute. As we mentioned, these organisms take up carbon dioxide, and they can do that much more readily when it’s highly concentrated, such as in the flue gases from a power plant. Using emissions to grow algae can thus cut down on the release of this worrisome greenhouse gas while producing the oils that are so sorely needed for biodiesel. After the oils have been extracted, the remaining residue can be burned to generate heat and power, or it can be turned into animal feed or nutritional supplements, such as omega-3 fatty acids and antioxidants. Not bad for simple pond scum.

Given this rosy picture, you’d be right to wonder why algal biofuels haven’t already taken off. It’s not as though people haven’t been working on the idea for a long time. One early research project, begun in 1978, was the U.S. Department of Energy’s Aquatic Species Program at the Solar Energy Research Institute, which later became the National Renewable Energy Laboratory. During this 18-year effort, the Department of Energy spent about US $25 million exploring virtually all aspects of algal biofuels. Researchers screened more than 3000 strains of algae for robustness and the ability to produce oil. These investigators eventually culled their collection to the 300 most promising species. Unfortunately, only a fraction of those cultures survived, necessitating our recent trips back into the field.

During the later years of the Aquatic Species Program, molecular biologists isolated key enzymes in algae and attempted to genetically modify some of them to produce more oil. Other researchers worked on cultivation techniques, constructing what they dubbed the Outdoor Test Facility, in Roswell, N.M., which had two shallow ponds, each 1000 square meters in size. There, the growth rate of the algae was sufficient to produce more than 9000 L of oil per hectare—very heartening news. Less heartening, though, was the observation that faster-growing wild strains with lower oil concentrations often ended up outcompeting the species being cultivated.

It also quickly became clear that the process the researchers were using to turn the algae into fuel wouldn’t be cost effective. As expensive as gasoline and diesel seem at the pump, they cost less than almost any liquid you can buy at the store. So to compete with petroleum, every step in the conversion of algae to fuel has to be done very cheaply.

Take the process of dewatering—that is, harvesting the algal cells from the suspension they’re growing in. It may look like pea soup, but that suspension consists mostly of water, with perhaps only 1 gram of algae in each liter. The technology of dewatering has improved, and the cost has come down since the Aquatic Species Program ended, but not nearly enough. Other steps in the conversion remain pricey, too. Recent estimates of wholesale costs of algae-derived biofuel fall between $10 and $35 per gallon ($3 to $9 per liter)—much too expensive to compete with petroleum-based fuels or even today’s vegetable-based biofuels.

To avoid issues such as light limitation and culture stability, Solazyme works on growing algal strains in the dark in large vats, converting sugars fed to them into oil or hydrocarbons.

Algenol uses an engineered strain of blue-green algae, better known as cyanobacteria, which uses photosynthesis to convert CO 2 into sugars and then ferment those sugars into ethanol, which the cells then secrete. This procedure eliminates the need to harvest and dry the algae and then extract the oils.

Both Aurora and Sapphire are developing improved species of algae for open-pond cultivation, while Solix focuses on the engineering of closed photobioreactors.

Recent advances in technology, however, might soon change this rather gloomy economic picture. For example, we can now grow thousands of cultures simultaneously at the microliter scale using advanced liquid-handling devices and robotics. Instruments can isolate single oil-filled cells from their cultures based on how the cells fluoresce. With our improved understanding of flow dynamics, we can engineer ponds and bioreactors that require the least amount of energy to mix. And new polymers that are both stronger and cheaper can withstand months of punishing sunlight, enabling more affordable photobioreactors. The technical challenges should not be underestimated, but our projections suggest that in the next 10 years or so algal biofuels will be able to compete economically with crude oil costing between $75 and $100 per barrel.

What makes us most optimistic is the renewed financial support for developing this technology. The U.S. Defense Advanced Research Projects Agency was among the first to begin funding research groups to work on the cost-effective conversion of algal oils to jet fuel. The Air Force Office of Scientific Research also issued a number of grants to academic and national labs to carry out such research. And the American Recovery and Reinvestment Act is providing $50 million over three years to a consortium of national, academic, and industrial laboratories, called the National Alliance for Advanced Biofuels and Bioproducts, to develop algae-based biofuels.

Private investment is substantial, too. A few start-ups stand out in this regard. In the past year, Algenol alone has raised more than $900 million from private investors. And in the same period, Aurora Algae, Sapphire Energy, Solazyme, and Solix Biofuels have each raised in excess of $10 million. Although their products are unlikely to be able to compete with conventional fuels anytime soon, the Defense Energy Support Center recently announced that it is prepared to buy more than 2.65 million L of algal biofuels at the cost of production for use in ships and jets. This guaranteed market should provide near-term revenue for such companies, allowing them to improve their processes and reduce costs.

We are confident that we’ve reached a sort of tipping point and that we’ll see algal fuel produced in larger quantities in the next few years. But before that happens, regulators will need to explore the environmental impact of scaling up algae production. We and others will have to evaluate the carbon footprint of these operations, as well as their water and nutrient demands. Another crucial question concerns what ecosystem changes might result from modifications to the land, the evaporation of huge amounts of water, and the disposal of leftover salty brines. Lastly, the cultivation of nonnative algal species presents an unknown risk to our aquatic environments. Government agencies will need to weigh the potential benefits of factors such as adding jobs in rural areas and energy security against any environmental consequences.

Clearly, many obstacles still stand in the way of widespread commercialization, but so far none of these issues strikes us as insurmountable. To our eyes, anyway, the future of these little green cells looks positively golden.

This article originally appeared in print as “Green Gold.”

About the Author

Philip T. Pienkos, Eric Jarvis, and Al Darzins, all veterans of biotechnology start-ups, are now molecular biologists at the National Renewable Energy Laboratory, in Golden, Colo. In “Green Gold,” they assess the potential of algae-based biofuels. The authors would like “to see algae biorefining follow the meat packers’ principle, where everything is used except for the oink.” Every molecule in an algal cell could be made into useful products, including nutritional supplements, animal feed, and fertilizers. Says Darzins, “The final chapter hasn’t been written for algae.”