Extending Life By Half

Licensed originally for just 40 years, one by one U.S. nuclear power plants are qualifying for 20 more

This is part of IEEE Spectrum's special report: Nuclear Power Gets a Second Look

Soon, most nuclear power plants in the United States, having gone on-line in the 1960s and 1970s, will be reaching the end of their 40-year operating licenses. If they are to continue operating, their licenses must be renewed, a process started 10 years ago by the U.S. Nuclear Regulatory Commission, in Rockville, Md.

The reasons for renewal are economic: the plants are almost paid for, and with construction out of the way, the costs of supplying electricity are finally competitive with those of other energy sources, such as coal and natural gas. But safety still concerns nuclear critics, troubled by the known and unknown hazards of aging. For example, cracks in the control rod mechanism, equipment at the heart of the reactor, were unforeseen and in fact previously thought not to exist. But they now seem a real aging problem after all, undermining confidence that more years of safe operation lie ahead.

So far, the licenses of a half-dozen reactors have been renewed: in spring of 2000, two at Maryland's Calvert Cliffs plant, in Lusby, and three at South Carolina's Oconee nuclear facility, in Seneca; and this past June, Arkansas Nuclear One Unit 1 in Russellville. The six were among the more than 40 percent of 103 operating U.S. reactors whose licenses will expire before 2015, perhaps while they are still capable of efficient and safe production. Forty reactors may soon join the six; 14 have renewal applications in the review pipeline at the Nuclear Regulatory Commission (NRC) and the other 26 are expected to apply for renewal within the next six years.

In all likelihood, most of the nuclear fleet will follow suit, encouraged by the pathbreaking experiences of Calvert Cliffs and Oconee. These have graded what started out as a steep and expensive learning curve for the technical and regulatory part of the renewal procedure. As a prime example of beating that learning curve, Christopher Grimes, director of the NRC license renewal and standards branch, cited the license renewal of reactor unit 1 at the Arkansas Nuclear One facility. In June, Arkansas sailed from application to approval in a mere 17 months, compared with two years for Calvert and Oconee--a speed that may surprise those conditioned to a byzantine NRC regulatory system.

Utilities and regulators alike now express confidence in the smooth path they have developed. "Our initial experience with our license renewal process, by almost all measures, appears to have been successful," commissioner Greta Joy Dicus told the 16th International Conference on Structural Mechanics in Reactor Technology, held in August in Washington, D.C.

Unimpressed, nuclear opponents persist in questioning what has largely been a quiet process and say that government's expedited efforts to renew plants hamper meaningful public input [see "The Public's Window"]. Meanwhile, the rush to renew makes watchdog groups queasy about elderly reactors. They warn of heightened health hazards from an even greater accumulation of nuclear waste at reactor sites. And because no plant has in actuality operated for a full 40 years, the prospect of their safe management for 20 years more invites disbelief.

In favor of renewal

With initial construction costs paid for, two more decades with low overhead make future nuclear power more competitive with coal-burning and other kinds of power generation. Economically, the utilities' decision to renew "is a no-brainer," said Alan Nelson, senior project manager for licensing at the Nuclear Energy Institute, the nuclear industry's Washington, D.C.-based trade group. The 20-year extension may not only justify the roughly $15 million it costs to navigate the renewal process but also in effect underwrite costly repairs and equipment replacement of high-priced items like steam generator systems that usually must be replaced sometime during a reactor's original 40-year term. "The economics, of course, of replacing the steam generators was made pretty simple by the issuance of the renewed license," Christopher H. Poindexter, chairman of Calvert's Constellation Energy Group, of Baltimore, Md., told a conference of the Institute of Nuclear Power Operations (INPO) last year in Atlanta, Ga.

The worst consequences of growing old have been the focus of reactor research for decades. They include the effects of high temperatures and pressures, radiation, reactive chemicals, and power output fluctuations. All these cause corrosion, fatigue, and embrittlement of a plant's material structure. Some systems, structures, and components, such as pumps and valves, have been designed for routine replacement and maintenance. But others were designed to last for a plant's lifetime. Would-be license renewers must demonstrate that original designs or later modifications can support aging systems for two decades more than the 40-year period originally in mind.

Aging issues for electrical systems were mapped out in the mid-1990s. The condition of insulated cables was the primary electrical engineering consideration required in a renewal application. The follow-up issue was how to evaluate all the cable systems in the plant efficiently--a challenge met by considering them in groups bound by specific spaces in the plant. "You can quickly OK about 98 percent of these spaces," said Paul Colaianni, the lead electrical engineer for Duke Energy's renewal efforts at Oconee. "This approach immediately gets you down to the areas that are real problems, like containment areas and steam tunnels." Colaianni is the author of a handbook, on the electrical aspects of license renewal, due out by year's end from the Electric Power Research Institute, in Palo Alto, Calif.

Top aging problems: corrosion and embrittlement

The six reactors so far renewed are pressurized-water reactors (PWRs), which comprise about two-thirds of the reactors in U.S. nuclear plants. Relicensing of the second major reactor species, the boiling-water reactors (BWRs), is currently under review for Georgia's Hatch nuclear plant, in Baxley. "PWRs and BWRs are reasonably similar in terms of aging management challenges," commented Grimes.

Corrosion does damage to both types of reactors, but especially the extensive metal piping in the steam-generating systems of the pressurized-water types. Cracks in steam generators could allow radioactive and non-radioactive waters to mix. At the hefty cost of upward of $150 million, replacement of steam-generating systems weighs perhaps most heavily in the cost-benefit analysis for deciding whether or not to seek renewal.

Then there's the pressure vessel, a reactor's critical boundary for containing radioactivity. The vessel's nemesis is embrittlement, especially as its great size--a height and width close to 4 meters and walls 22 cm thick or more--makes it difficult to replace. Under neutron bombardment the vessel walls might become brittle, crack, and release coolant [see photo]. They are especially likely to succumb if made of copper and nickel alloys, as at the Yankee Rowe plant in Massachusetts shut down in 1991.

Precautions are taken. Reactor operators routinely address safety and technical aspects through equipment inspections, repairs, and replacement. They also recalculate the safe reactor operating limits, which can affect the power output, based on projections, of, how brittle the reactor is.

Plus, racks in a key reactor part

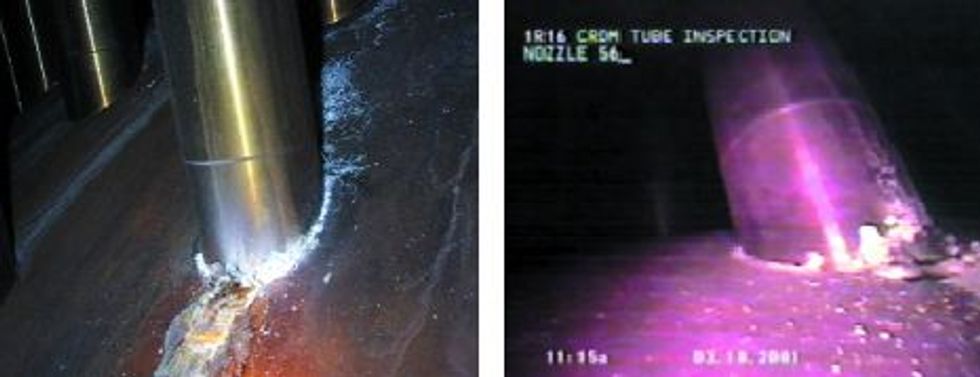

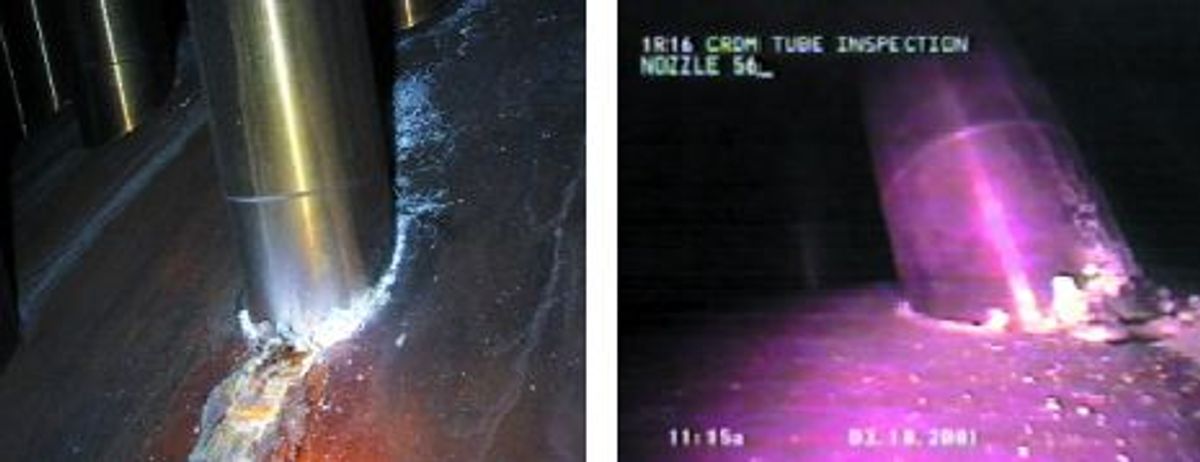

One recent unwelcome development involves cracks in the tubes, or nozzles, that are part of a reactor's control-rod drive mechanism. The nozzles are about 1.5 meters long and protrude about 15 cm into the reactor's pressure vessel head [see diagram]. The reactor's control rods are fitted through the nozzles and are lowered by the drive mechanism when the reactor is being shut down in an emergency. The nozzles form a critical part of the vessel's pressure boundary and, obviously, if cracked, may compromise reactor coolant system integrity. The NRC's Grimes calls them aging management's "most recent challenge."

In February, a routine inspection of Oconee 3's reactor showed a number of nozzle cracks due to stress corrosion by the primary coolant water. The cracks extended almost half way around the circumference of nine of its 69 control-rod nozzles. Oconee repaired the nozzles before starting up again in late April. However, also in April, a similar crack was found in a nozzle in Oconee 2's pressure vessel.

In 1997, the NRC had concluded such "circumferential" cracks were not likely to occur. The focus then was on cracks along the nozzle axis, perpendicular to the vessel head, which were deemed not a safety concern. Now the NRC says the safety implications must be reconsidered. If circumferential cracks in the nozzles split open, the nozzles could break, causing a dangerous loss of radioactive coolant.

Cracked nozzles in Oconee's reactors raise fears that similar defects may be found industrywide. So, in August, the NRC issued a bulletin (a request of all licensees to address the issue and respond by a given deadline) to all pressurized-water reactor licensees for comment on how they would inspect for and resolve this new cracking problem. "The significance of it is apparent, its severity illustrated by the issuing of the bulletin, the first since 1997," said Allen L. Hiser, an NRC materials engineer.

Oconee, for one, has already said it will replace vessel heads on its three units in the next few years. Depending on costs, inspection and repair are also a standard strategy. Hiser said that, after review of responses to the August bulletin, the NRC will decide what kind of industry-wide safety rule might be necessary to manage the problem. Nuclear industry critics have already weighed in with their preferred strategy. "Anything short of replacing this broken equipment needlessly endangers the public," said David Lochbaum, a Washington, D.C.-based nuclear safety engineer at the Union of Concerned Scientists, a nuclear watchdog group.

In her speech at the August meeting on reactor structural mechanics, commissioner Dicus soft-pedaled the circumferential cracking around control-rod drive penetrations found at Oconee. These were a reminder "that age-related degradation is an issue that can affect all operating reactors," she told her audience, and the event "should also help to emphasize the importance and strength of our current processes to deal effectively with emergent safety concerns."

Many in the nuclear industry share that confidence about the safety and effectiveness of aging-management programs. They stress that only safe plants operate, regardless of age, and that at no point does having an extended license allow a plant to run unsafely. But some do not agree. Watchdog groups say temporary reactor shutdowns due to age-related problems over the last few years cast doubt on the effectiveness of those aging-management programs. They also say that events such as nozzle cracking in the control rod mechanisms highlight how unknown and dangerous aging problems may continue to crop up unexpectedly.