A Less Well-Oiled War Machine

The high cost of petroleum is forcing the U.S. military to turn to solar, geothermal, and wind energy

In the middle of the Mojave Desert, a nondescript two-story building behind a gated fence houses an unlikely group of geologists. Their lineage is strong: several generations of prospectors have been drawn to dig in this dry corner. Within 100 kilometers of the geologists’ base near China Lake, Calif., 19th-century gold diggers stumbled on riches, and later oilmen got lucky in the same inhospitable soil. Now these earth-minded fellows have grand ambitions of their own. Their aim is to turn the U.S. Department of Defense into one of the world’s largest users of geothermal energy.

Their vision isn’t all a pipe dream. The rising cost of fuel has the Pentagon pressuring the four branches of the armed services to cut their energy bills wherever they can. It’s easy to see why—every US $10 increase in the price of a barrel of oil costs the Air Force, for example, an extra $600 million. The Army, Navy, and Marines, too, are tearing through their budgets. In response, energy managers at bases across the country are reevaluating how they light, insulate, heat, and cool their buildings. The most ambitious of these managers have begun aggressively adopting renewable-energy technologies. Together they have emerged as a distributed network of clean-energy advocates. The irony, of course, is that these military men and women should form such a group at the heart of one of the most energy-intensive operations on the planet.

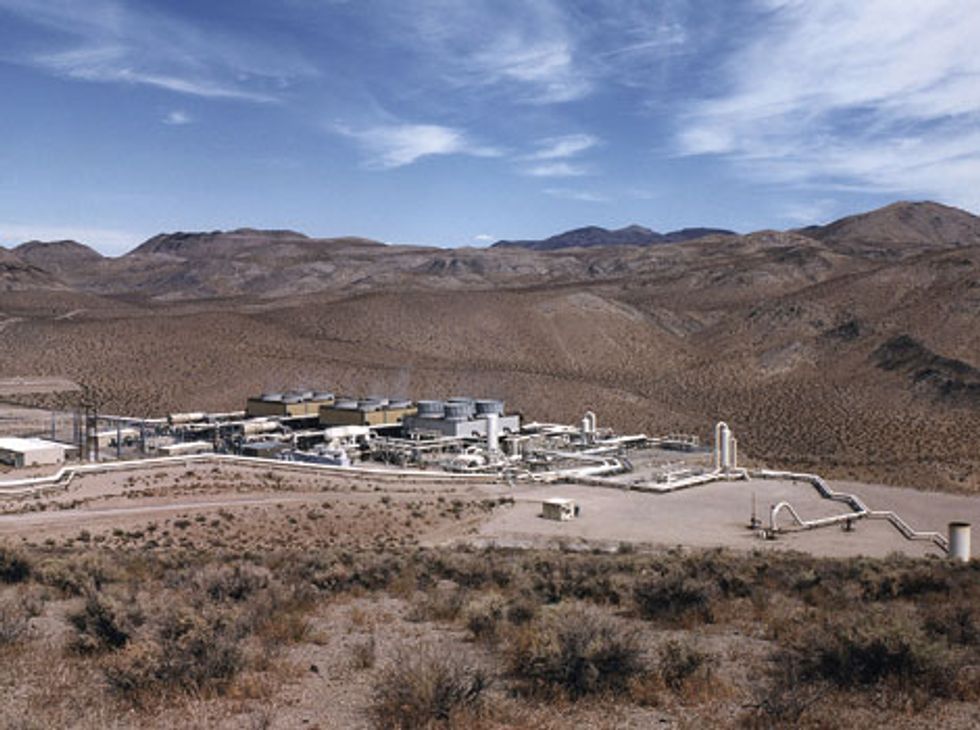

Among them are these desert geologists. Employed by the Navy, they are responsible for one of the largest geothermal power plants in the United States, a 270-megawatt generation facility at Coso Hot Springs, at China Lake. In the next few years, these scientists hope to figure prominently in a Department of Defense plan to generate 25 percent of its electricity from renewable sources by 2025.

For an organization that spent $13 billion on energy in 2007 and has a War on Terror to finance, whittling away at domestic electricity bills, which account for only one-fourth of that figure, may seem like a silly exercise. The scale of the projects and the savings, though, prove that the military is not merely indulging in a public-relations ploy. Not counting the geothermal power plant, the Defense Department says that in fiscal year 2007 it had produced or bought enough renewable energy to cover 11.9 percent of its electricity needs, which amounts to about 1.3 trillion kilojoules a year.

“There’s been a shift in the last five years, where more people are actively trying to do the right thing inside the agencies, and I don’t believe it’s simply because of high energy costs,” says John Archibald, a former deputy director of the U.S. Department of Energy’s Federal Energy Management Program. “Many are aware of the global-warming issue, and quite a few have signed on that this is something we need to address.” Until recently, military planning and environmental stewardship rarely overlapped, except when it came to cleaning up toxic-waste sites and managing “the bugs and bunnies,” as some government officials refer to habitat-conservation projects on federal land.

That attitude has begun to change. Many defense staffers cite specific legislation—the Energy Policy Act of 2005, which set clean-energy milestones for the federal government, and the Energy Independence and Security Act of 2007, which adopted the 2025 benchmark as a goal for the whole country. But the language surrounding the goal is weak and provides no direction. To Thomas Morehouse, a consultant for the Institute for Defense Analyses, a think tank in Alexandria, Va., the energy legislation alone doesn’t explain the DOD’s greenish inclinations. “There is no energy policy. There is no coordinated Defense Department program for renewable-energy deployment and no single office in the Pentagon that tracks it,” he says. “The projects so far happened largely because you get a particular base commander somewhere who’s enthusiastic about doing this and puts in the effort to make it happen.”

Indeed, bolstered by edicts from the upper echelons of government, energy managers at individual bases have begun to act on a conviction that climate change and a constricted energy supply could make for an ugly future. What has emerged is a patchwork of energy-sustainability projects. Some of them have been record setting, others are barely noticeable, but together they attest to a growing concern about the DOD’s annual consumption of some 912 terajoules, almost 1 percent of U.S. energy use.

As Don Juhasz, chief of energy and utilities for the U.S. Army, puts it, “There are enough of us deep within the DOD who see that, long term, if we’re going to be here 50 years from now, we need to be leaders and drive the country towards the future we want. We need to set the example.”

The Naval Air Weapons Station, in China Lake, Calif., sits on a hilly plot of arid land about 240 km east of Los Angeles. The California wildfires recently smoldered down from the mountains to the west, but a sudden downpour this past July briefly painted the Joshua trees and ankle-high brush a perky green. From the Geothermal Program Office, manager Andrew Sabin dispatches his crew to check out promising geothermal spots across the Southwest. This summer, they were investigating California’s Chocolate Mountains, where the Navy and Marines test aerial weapons. “It’s probably one of the hottest spots on Earth, literally and figuratively,” Sabin says. In theory, this region could produce more than 600 MW, an enormous figure given that the total geothermal electric power generation in the United States today adds up to about 3000 MW, according to the Geothermal Energy Association.

Simply put, a geothermal power plant generates electricity through wells that can reach thousands of meters into the Earth. The wells bring heat to the surface by drawing hot water or steam from high-temperature cracks in the Earth with fluid flowing through them. That water or steam then drives turbine generators. Finding the best spots to drill those deep wells, however, can be tricky and expensive.

Initially, geologists exploring a site look for the most obvious beacons, such as the bubbling mud puddles and fumaroles that send up clouds of steam in the hillside around the Navy’s China Lake base. Even a quick scan through Google Earth images can reveal some promising linear features that could turn out to be faults. Once a site is chosen, the geologists analyze the rocks, inspect soil densities, and study the chemical characteristics of subsurface water. This past summer, they were gathering data on variations in the area’s magnetic and gravitational fields. The flow of liquid along a fault over time can alter the mineral makeup of the rocks, changing the local magnetic field. An unexpected magnetometer reading suggests the presence of a flowing fluid in the rock, and therefore also points to a well-defined fault.

But none of those data are enough to positively identify a geothermal hot spot. “Until we drill a hole in the ground, I know as much about this rock as you do,” says Steven Bjornstad, the senior geologist on staff at the Geothermal Program Office, adding, “Some day I hope I can stop saying that.” After decades of research on ways to rely less on drilling, the office has just begun experimenting with lidar imagery, which should add more certainty to the site selections. The office has commissioned an aircraft to fly over a long north-south valley west of the Chocolate Mountains to generate maps from a laser scanner that sends trillions of photons down to Earth and measures the length of time before they are reflected back. “We know there’s high heat flow and fluid, and now we’re looking for active faults,” Sabin explains. “Any structures would be very, very subtle, but we’re hoping that with lidar they’ll jump right out at us.” Coupled with a digital model of the area’s elevation, certain lidar patterns can seem, to the trained eye, distinctly like a fault.

Though lidar has been around for some time, only recently has the image resolution—and interest—been high enough to make it worth pursuing. “Ten years ago when we went knocking on doors, we got no response. Now when we come calling, the base commanders are interested and we can have a conversation,” Sabin says. But geothermal development always starts small; the inscrutability of this deep-seated resource tends to make developers shy. A contractor has agreed to install a 30-MW power plant at Naval Air Station Fallon, in Nevada, even though the production capacity of the field could be as much as 160 MW. The leadership at another Nevada base, Hawthorne Army Depot, has also welcomed exploration on its base.

Sabin, Bjornstad, and their crew of eight others are arguably the most organized and well-funded entity promoting geothermal development within the United States. Their office’s operation is underwritten entirely by what the Navy earns from its agreement with the power plant’s operators—about $14.7 million a year. A third of that goes to the geothermal office, and the rest pays for energy projects within the Navy that might otherwise struggle for support.

One of those projects is a set of studies assessing the feasibility of wind turbines. At Naval Air Station Corpus Christi, in Texas, anemometers 30 meters up in the air measure daily wind speeds around the base. “This bay is the windsurfing capital of the world—it’s always windy. But even knowing that, there can still be risk for an energy-services contractor to put up a turbine,” says Chris Tindal, the deputy director of the Navy’s Shore Energy Program. “But if we’ve already collected the wind data, it’ll lower their risk and lower the price, and that’s the big key for us.”

If the Navy follows through, these commercial-scale wind turbines will be its first in the continental United States. Up to now, the Navy has used them only at offshore locations like San Clemente Island, a naval base 126 km west of San Diego, and Guantánamo Bay, Cuba, where four 950-kilowatt wind turbines have been spinning since 2005. Because Cuba provides no electricity to the base, a 3.8-MW hybrid wind and diesel-generator plant saves the service $1.2 million a year in the form of fuel that no longer needs to be transported to the island.

Back in the Mojave desert, far from Guantánamo, a different renewable-energy project demonstrates the surprising economics that can come into play. A 14-MW photovoltaic array—the largest in the Americas—has been generating electricity for almost a year. To a pilot’s eye, the rows of black rectangles form dotted lines on the rocky beige landscape on which Nellis Air Force Base sprawls, about 15 km northeast of the Las Vegas strip.

Every few minutes, hundreds of half-horsepower motors purr as the 72 416 panels tilt a few centimeters to the west. Balanced on stout little concrete feet, 56 hectares (140 acres) of panels follow the sun like worshipful robots. But as dusk approaches, the solar panels change their course: they start to tilt backward, to the east, their black faces leaning away from the sun. The engineers on the project, from SunPower Corp., based in San Jose, Calif., found that if the panels turn westward as dusk approaches, the shadows cast by some panels onto others lead to a greater loss of efficiency than if the solar cells soaked up rays while lying more or less flat, at an oblique angle to the descending sun.

Dictating those finely plotted movements are computer-controlled trackers designed by SunPower (which also manufactured some of the solar cells, along with Evergreen Solar, Sanyo, and Suntech Power). The panels, fixed at a 20-degree southward tilt, rotate from east to west in response to the trackers’ cues. Each string of a few dozen solar pods has its own motor and a controller. The controller feeds data to an inverter, which is remotely monitored in the system’s control room. On a hillier section of the installation, the strings are programmed to move along paths that take the terrain into account. “It’s a funny sight when something does go wrong, because one row will point in a completely different direction from everything else around it,” says Michelle Price, Nellis’s energy manager.

To check on the system’s performance, weather stations throughout the site record air temperatures, wind speeds, and solar radiation. A monitoring algorithm uses those environmental measurements to calculate how much electricity the system should be generating at any given time. “It was the first time we installed this tracker in the United States and the first time that we did a tilted tracker,” says Julie Blunden, SunPower’s vice president for public policy and corporate communications. The tilting and tracking, Blunden says, allow the field to generate 30 percent more energy than if the panels were fixed in place.

But the cost of all those trackers, inverters, cells, and concrete pedestals adds up—to more than $100 million, in this case—and breaking even on such a system could take half a century. That’s where Nevada’s renewable-energy laws come into play, in particular the one that requires the state’s utilities to increase the amount of electricity generated from renewable sources by 3 percent every two years. That legislation created a big incentive for Nevada Power, the local utility, to see that the Nellis solar field came into existence.

The project started with a voice-mail pitch left on Steve Dumont’s phone by a solar-energy developer, in 2004. Dumont, the energy program manager for Air Combat Command, initially ignored the proposal. But then, he says, “I did a back-of-the-envelope calculation, and pretty quickly I saw that this could work.” From there, it was a matter of convincing others in the Air Force to submit a proposal for the project to Nevada Power. “It took two years of telling people that it was a great idea, that we think the economics are there, and that we might even be able to get a good deal out of it,” Dumont says.

Nellis’s energy staff moved ahead. First, they combed through project proposals that they’d solicited and then zeroed in on the SunPower system. The base agreed to lease out the land for the project at a nominal fee. A financing company, MMA Renewable Ventures, was brought in to pay the up-front costs; it now owns the equipment and sells the power to the base. MMA then sold the renewable-energy certificates it acquired for the installation—each certificate usually represents the “green attributes” of 1 megawatt-hour—to Nevada Power. As a result, only the utility can claim credit for the solar energy that, technically, MMA provides and Nellis consumes.

The outcome of these business negotiations was more dramatic than anyone at Nellis had expected. The base agreed to pay 2.2 cents per kilowatt-hour, down from about 7 cents, which is what it had originally paid, for the next 20 years. “I’ve received hundreds of phone calls from people asking me about ‘the Nellis model,’ ” says Price, the energy manager. The conditions may be hard to duplicate, but that won’t stop people from trying—Price has hosted visits from mayors, senators, and even representatives of the Walt Disney Co. David Felix, a senior manager at MMA, predicts a second wave of solar projects on military lands in the near future. “You can see the other requests for proposals that have been issued since. Davis-Monthan, Fallon, Edwards, and many others have expressed interest in following suit,” notes Felix, ticking off the bases that could become future clients.

Dumont also expects to develop more solar energy projects, starting with Davis-Monthan Air Force Base, in Arizona. “The more we put these big ones in, the more we help the industry to reach its prime.”

One man closely watching the Nellis saga unfold is Chris Archer, the deputy base civil engineer at McGuire Air Force Base, in New Jersey. On a recent summer morning, Archer surveyed his turf with a keen eye for flat roofs and unobstructed empty fields. Every few minutes, a C-17 cargo aircraft took off on a delivery run and another came in for landing at the base’s active airfield. “They’ve cracked the code on how to do big solar, and that makes it easier for us,” Archer says of the Nellis installation.

He has a big job on his hands—to make McGuire, 24 km outside Trenton, able to go completely off-grid by 2015. McGuire is one of two model energy bases chosen by the Air Force last year to explore energy efficiency to the fullest extent economically possible. A base in New Jersey is a logical starting point: between the state’s generous renewable-energy credits and a relatively high electricity price (13 cents per kilowatt-hour, compared with a national average of 9 cents), the Air Force stands to gain from easing its draw. In the year since he began his mission, Archer has replaced a poorly insulated 2-hectare (5-acre) roof on a warehouse and begun installing smart meters on large buildings to track their energy use.

In that one year, electricity use dropped by 14 percent. “We’ve been addressing all the low-hanging fruit,” Archer says with a modest shrug. His task list now includes putting 100 kilowatts’ worth of solar panels on several warehouse roofs, replacing 1970s-era lighting, and dismantling the central heating plant by installing more-efficient furnaces in some buildings and ground-source heat pumps underneath others. Those units use the thermal stability of the Earth to transfer heat to a building from the ground through geothermal wells dug about 120 meters deep.

“At first I think the Air Force and McGuire struggled with what this model-energy idea means,” says Joseph Bogdan, McGuire’s energy manager. Now that the team of civil and electrical engineers has gained momentum, he and Archer think they’ll be able to halve the electricity consumed at McGuire from its 2003 level by 2011. They are also in the beginning stages of developing solar and biomass power plants.

Specifically, they want to install a 2-MW solar array in an empty field between a dormitory and two day-care centers on the base. Archer periodically checks out the location, just a minute’s drive from his office on base. “Can you imagine?” he says, hands on his hips as he scans the field on a recent visit. “These children will grow up playing right next to all these solar panels, and to them it’ll look completely normal.” He’s optimistic that a 6-MW solar installation on a brownfield on the edge of the base won’t be far behind. “I think we’re going to be able to carve out a deal, maybe even better than what Nellis did,” he says. To meet McGuire’s routine electrical demand of 12 MW, they’ll need something on that scale.

But not every base has access to renewable-energy incentive programs or giant naturally occurring geothermal resources. The Army has a similar goal of five net-zero-energy bases by 2015, where, over the course of a year, the base or buildings would produce more energy on site than they consume from the grid or from other fossil sources. In states that lack strong support for renewable energy, keeping it affordable can be challenging.

That was William Stein’s experience during his decade as the energy manager at Fort Huachuca, in Arizona. Using a combination of third-party financing and small sums from the Army, he trimmed electricity use by 1 percent at a time when the base and its population were expanding. In addition to replacing inefficient lighting and repairing a broken solar-heated pool, Stein procured several rooftop solar panels, installed a 10-kW wind turbine, and put in two of the military’s first solar-collector walls. Here, the sun’s radiation warms a heat-collecting panel installed parallel to a building’s exterior, most commonly several centimeters away from its south-facing side. Fans draw the heat into an air cavity between the panel and the building, and that air in turn provides heat and ventilation for the occupants of the building. Such solar-heating systems have since become a hit on Army bases—this past spring, Fort Drum, in New York, finished installing 50 solar walls made by Toronto-based Conserval Engineering.

“We’re trying to be leading edge, bleeding edge, but the problem is we get a lot of resistance,” Stein says. “It’s not all doom and gloom, but we’ve got to turn the ship very, very slowly.” His work won him the title of energy champion and got his face on a poster in Army offices in Washington, D.C. He now manages the national program for the Army’s net-zero-energy bases, which his boss, Don Juhasz, hopes will be the service’s main contribution to meeting the Defense Department’s mandate of 25 percent renewable energy by 2025—once they figure out how to do it.

Some military employees hope that the arguments for renewable energy are compounding in their favor. This past February, a report released by a Defense Science Board task force on energy strategy concluded that the vulnerability of the national electric grid to attack or failure could compromise the ability of domestic bases to carry out their missions. Though each base has backup diesel generators to power critical buildings, well-placed renewable-energy technologies could stretch a base’s supply of diesel fuel, if not replace it, in an emergency.

The reasons to deploy renewable-energy technologies are compelling, but Brad Hancock, the DOD’s associate director for energy and utilities, sees a gap between what the bases want to do and what they can do on their own. “We’re mostly looking in the 100-kW to the little-smaller-than-a-megawatt range, to have security of energy and to lock in electricity prices,” he says of the projects that the department chooses to fund internally. “We want to produce enough renewable energy, but we’re still struggling with the life-cycle cost issues.”

Chris Tindal, the Navy’s shore-energy manager, sums up the military’s operating philosophy succinctly. “If we can buy more ships, more planes, more bullets, that’s what we’d rather do than put our money into infrastructure,” he says. In other words, that’s why military dollars are always in short supply for domestic energy projects. But that position also explains, in light of an uncertain energy future and a handful of stunning economic successes, why some individuals are inching the military toward a cleaner, more sustainable stance on power. Their work is really paying off, too: as Hancock sees it, the military is “more than on track” to fulfill its vision for 2025. With some bases supplying their own electricity and vast empty stretches of military land being used to produce power, the U.S. military, at least at home, is at the forefront of an energy revolution.

To Probe Further

For more on the military’s use of alternate energy, see Slideshow: Powering a Far-flung Military