March of the Pico Projectors

They all do the same thing—get a big picture out of a tiny device. But there are lots of ways to do it

More than ever before, we are flocking to a gaggle of tiny devices for entertainment. We watch movies on iPods and use our mobile phones to show our family photos and to watch live TV. We bump shoulders as we crowd around the minuscule screens, fumble for reading glasses, and tilt the displays back and forth to find workable viewing angles. If we’re old enough, we pine for the good old days of drive-in movies, with their vast screens.

We love multimedia content, and we also love the convenience of enjoying it wherever we are and whenever we want. But can we continue to put the two together without turning into perennial squinters?

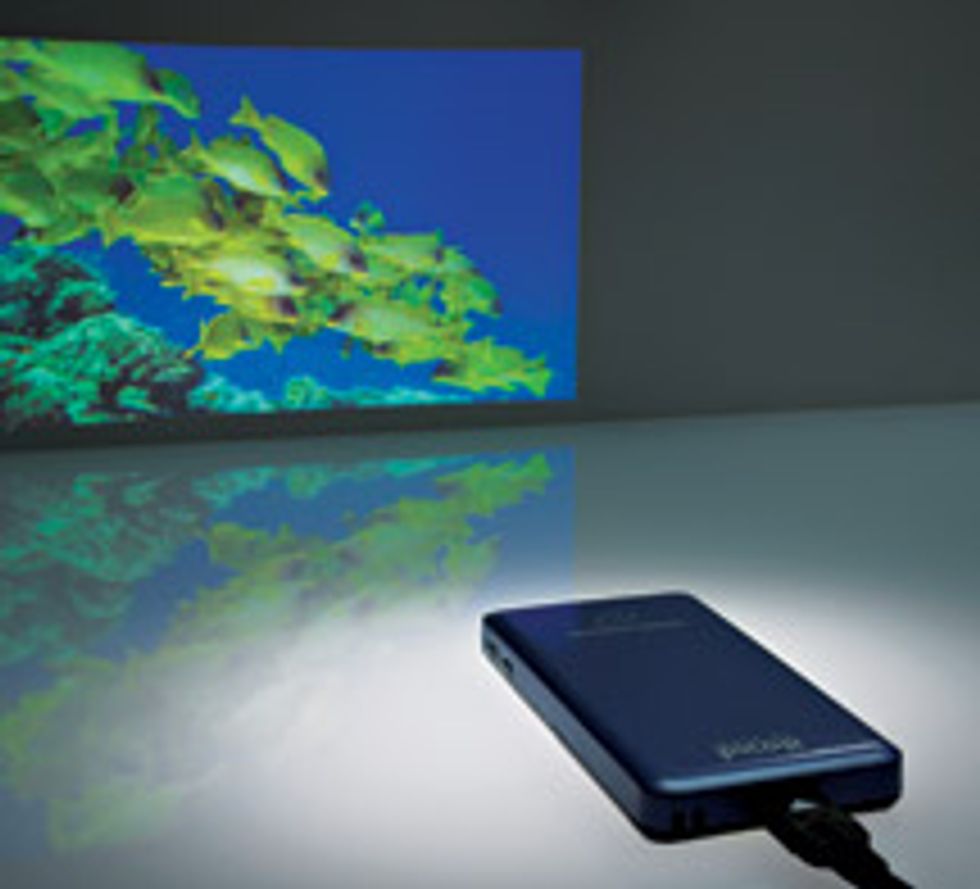

We sure can! Behold the ultraminiature, or “pico,” projector. From now on, the dimensions of the device in your hand will no longer dictate the size of the viewing screen.

The first generation of pico projectors hit the market in 2008. They weren’t much—clunky little boxes that produced low-quality images and had to be cabled to a computer or PDA. Very few people bought them.

Turns out that what people really want is a mobile phone, music player, laptop, or camera that projects big, bright, and sharp images—or an extremely tiny plug-in projector compatible with all those devices. This year, they’re going to get what they want. We’re just now starting to see the next generation of pico projectors, and besides being in smaller stand-alone devices, they’re coming embedded in cameras, media-storage devices, and a few smartphones—about 100 individual products so far. Over the next few years they’ll be popping up in more products and are likely to be the hottest new feature in mobile devices since the cellphone video camera. In fact, market research firm Insight Media forecasts shipments of embedded pico projectors—in consumer electronics, cars, industrial applications, and medical equipment, as well as in cellphones—to reach 30.8 million units in 2014, up from about 1 million units in 2009.

What a pico projector does is simple: It takes a digital image and sends it out as a beam of light, creating an image that’s much bigger than the originating device. Aim that beam at, say, the tray table nestled into the airline seat in front of you and you’ve got a miniature movie theater. Or aim it at a dark ceiling and you’ve got a display with a diagonal of some 60 inches or larger.

To do this, every pico projector needs chips to process and decode the image data for the hardware; a light source, typically LEDs or laser diodes; and mirrors and optics, to direct and focus the image.

Pico-projector technologies differ in how they turn light into the pixels that make up a video image. The battle between plasma and LCD for dominance in flat-screen television was heated and confusing (LCD won, if you missed it). The battle for the heart of the pico projector is shaping up to be much more complicated, because to date there are three vastly different technologies—liquid-crystal-on-silicon (LCOS) microdisplays, digital light-processing (DLP) devices, and scanning-mirror systems (also called laser-beam steering systems, or LBS)—and there are even significantly different design approaches within these three categories. Some of the leading players in this game so far are Aurora Systems, Himax Technologies, Light Blue Optics , Micron Technology (through its acquisition of Displaytech), Microvision, Syndiant, Texas Instruments, and 3M. With an estimated market of US $1.1 billion at stake by the year 2014, according to market research firm In-Stat, we’re going to see a good old-fashioned consumer-electronics footrace.

Two of the first technologies to make it into commercial pico projectors were LCOS and DLP. But their hold is anything but secure: The scanning-mirror systems are about to mount a serious challenge.

LCOS was developed in the late 1990s by JVC, which used it for large-screen projection televisions. In LCOS, liquid crystals sit directly on a silicon chip that has been coated to act as a mirror. The liquid crystals change their orientations in response to an electric field; as their orientations change, so does the polarization of light that travels through the liquid-crystal layer and reflects off the coating. A polarizing beam splitter at the front of the LCOS imager, acting like a goalie of sorts, either allows light to pass straight through or redirects it. When the crystals align with the polarizing beam splitter, the beam splitter lets the light through to reflect off the chip, where it bounces back to create an “on” pixel. When the crystals are out of alignment, the beam splitter blocks the light to create an “off” pixel. And in between on and off states, the crystals can allow different intensities of light to reflect. Refreshing the individual pixels on the chip dozens of times per second creates a moving image.

In projection TVs and digital cinema, designers use three LCOS chips. A beam of red light is aimed at one chip, green at another chip, and blue at a third. The three resulting images are sent through lenses to combine them into one full-color image on the screen.

At pico-projector sizes, however, there just isn’t enough room for three LCOS chips, so designers had to come up with another way to separate an image into its three primary color components. Actually, they came up with two ways: color sequential and color filtering.

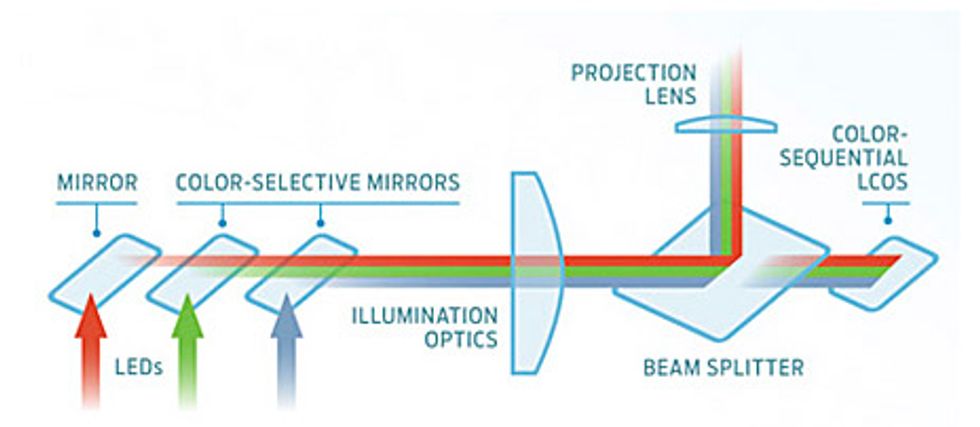

Color-sequential LCOS is the more common method. Red, green, and blue LEDs or laser diodes—one of each—flash sequentially at a single LCOS panel, which adjusts how much of each color for each pixel is projected. When the device uses LEDs, a reflective cone surrounds each light, directing it to the LCOS panel in the same way a flashlight directs its beam of light forward. When the device uses lasers, direction isn’t an issue; instead, lenses in between the lasers and the panel spread the tightly focused beam of light to cover the entire panel. In both LED and laser LCOS projectors, the light, after bouncing off the panel, travels through a set of lenses that enlarge and focus the final image.

Aurora, Micron, and Syndiant all use the color-sequential approach in the pico-projector modules they sell to consumer electronics companies. Himax is now developing a module for a color-sequential projector intended for consumer products.

Color-filtering LCOS uses a single white LED as the light source, creating color by sending that light through red, green, and blue filters. The light follows the same path as in color-sequential LCOS—reflecting from the panel and then passing through enlarging and focusing lenses on the way out of the device. The filters, however, make for a more complex LCOS panel, because each of the three subpixels requires an independent electrode to control its status: on, off, or somewhere in between.

On the plus side, product designers can fit color-filtering LCOS into a small space, because they have only one light source to deal with. On the minus side, the filters reduce the amount of light that gets to the screen by up to two-thirds, and some of the colors bleed together, reducing color quality. Plus it’s difficult to get good manufacturing yields; the three subpixels mean that the chip design is three times as complex.

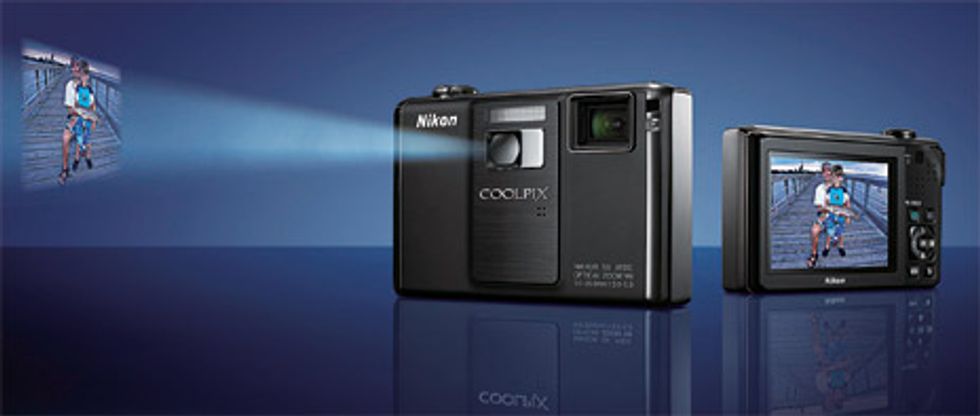

Aurora, Himax, and Micron are producing or will soon produce color-filtering pico projectors, and Nikon has built the technology into its Coolpix S1000pj compact digital camera, already in stores.

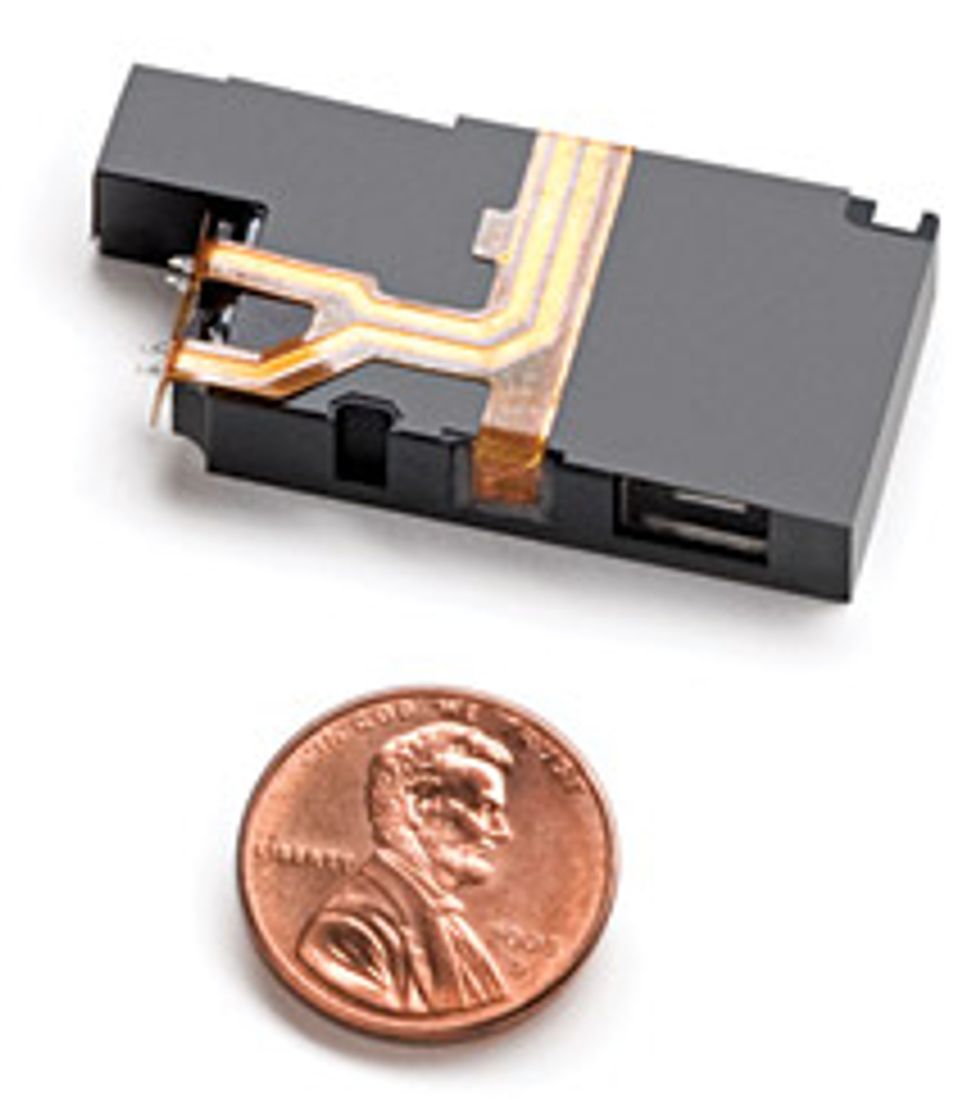

Like LCOS, DLP technology came to the pico-projector world from projection television (perhaps just in time for DLP’s survival in the mass market, as market research firm International Data Corp. predicts that rear-projection TV sales will plunge to nearly zero by next year). DLP chips, invented by Texas Instruments in 1987, each contain a rectangular array of up to 2 million hinge-mounted microscopic mirrors. You can fit five of these mirrors across the width of a human hair. These micromirrors create pixels by tilting toward the light source (on) or away from it (off) as red, green, and blue light alternately shines onto them.

Because of the complexity of the chip, it tends to be a little more difficult to manufacture than its competitors. But the technology is relatively stable. And because DLP is used in digital projectors in movie theaters, it has already had its high-resolution shakeout, a challenge that’s still in the future for most of the other pico-projection technologies.

Unlike DLP and LCoS, which were both adapted from television, scanning-mirror systems originated from contracts with the U.S. military for development of head-mounted displays that project an image directly onto the eye, a concept on which work still continues. Their imagery is extremely sharp, has the highest contrast of the three technologies, and potentially could be produced in the smallest package. The main drawback, however, is that, at least in the short term, they are more expensive than the competition, for they rely on three separate high-frequency lasers as the light source, and the light source makes up at least a third of the cost of the product.

Let’s take a closer look at those laser components. In a full-color laser system, you need red, green, and blue laser-light sources. Red diodes are readily available—they’re in all consumer CD players. Blue—actually, almost violet—laser diodes were first developed by Shuji Nakamura at Nichia Chemical Industries in 1997. Today they’re used in Blu-ray DVD players, so they’re also widely available and can be adapted for mobile projectors. True green-laser diodes, however, are not yet commercially available. But companies like Corning, Osram (a Siemens subsidiary), and others have come up with a mechanism that bounces laser light in a cavity between two crystals and doubles its frequency. With this technology, an infrared laser can produce a suitable green to meet current demand. Next-generation green lasers are likely to be simple green-laser diodes, with size and price advantages. While this new crop of green-laser diodes should come to market within the next year or two, both technologies will coexist for the foreseeable future.

Why go through all this hassle to use three lasers? For one, laser-based systems don’t have to struggle with filters that dim the light or with other means of generating multiple colors from a single light source. Because laser light is inherently tightly focused, laser-based systems don’t need a movable lens for focusing. And scanning laser systems also dispense with the expansion lens needed for laser-lit physical arrays, whether they’re LCOS or DLP. Lenses introduce losses, distortion, color changes, and other aberrations. But the real advantage is package size. Mobile-device makers value every cubic millimeter. A smaller size and reduced complexity are precisely the characteristics needed to crack that huge mobile phone market. The pure light of lasers also allows these systems to produce a huge range of colors—twice that of broadcast television—and very high contrast ratios, as much as five times those of DLP and LCOS projectors. A downside of laser-based systems is a phenomenon called laser speckle, which occurs when the beams of light scatter randomly off imperfections in the projection surface and interfere with one another to create patterns of light. It can look a bit like someone tossed a handful of glitter on the screen. For the most part, the speckle is down to an acceptable level, but developers are still trying to eradicate it.

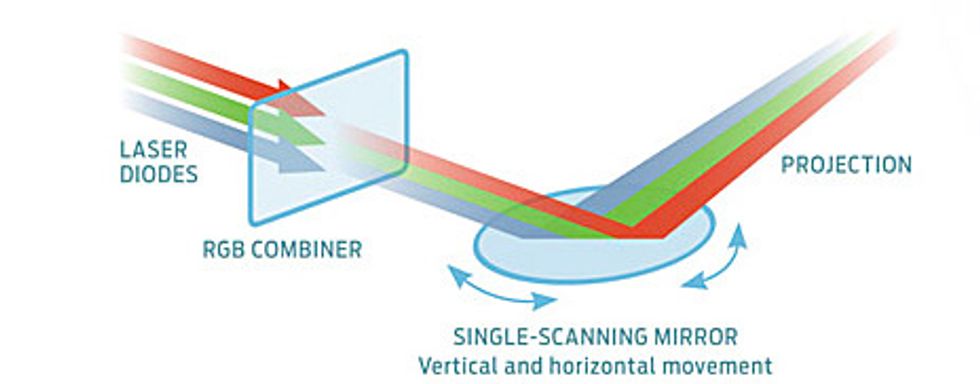

So all scanning-mirror systems start with three lasers. The red, green, and blue beams change power, going from totally off to barely on and all the way to fully on, depending on the color of the pixel being displayed. Unlike the three colored lights in color-sequential LCOS, the lasers often shine simultaneously, not sequentially. To display purple, for example, both the red and the blue lasers shine at once.

Each laser sends its beam through lenses that direct it to the center of a mirror (or mirrors). These mirrors are microelectromechanical devices manufactured on silicon, similar to computer chips. Now here’s where the scanning-mirror systems diverge into two types: single scanning and dual scanning. In a single-scanning mirror system, one mirror directs the laser beam, painting horizontal lines back and forth to create a frame of the moving image. At the end of each line, the beam shifts vertically, and then, when the screen image is complete, the beam zips back to the top and starts again for the next frame. In a dual-scanning mirror system, one mirror directs the laser light back and forth along a horizontal path and then sends it to another mirror that adjusts the vertical position of that horizontal line, moving it down the virtual screen.

All mirror systems send the image back out through lenses that correct for distortion introduced by the curve of the mirror (or mirrors). Two-mirror systems create less distortion to correct, but the second mirror has to catch the spread-out beam of the first mirror. If the mirror is out of alignment, the effect on the final image can be dramatic.

Late last year, Microvision began shipping a product called ShowWX, based on a single-scanning mirror. (Full disclosure: The author is a product manager at Microvision.) Maradin Technologies, in Israel, is also developing a single-scanning mirror system and aims to have a commercial product in a few months. The Nippon Signal Co. and the Israeli company bTendo have publicly demonstrated two-mirror systems.

Some pico-projector designers are trying to combine the low cost and durability of LCOS technology with the rich colors and tight focus of laser light in a technology known as holographic laser projection. The underlying concept is pretty complicated (see sidebar, “A Projector of a Different Color”) but remarkably effective. In brief, instead of producing the image in the time-honored way—as a grid of pixels—the technology recalculates the image into a set of diffraction patterns, or holograms. The holograms appear sequentially on an LCOS display and, when a laser light shines on the display, the holograms create an image projected on a surface.

Light Blue Optics, in Cambridge, England, is the first company to announce a commercial product using this technology. The company demonstrated a reference product, Light Touch, at the January 2010 Consumer Electronics Show, in Las Vegas, that turns a flat surface into a 10.1-inch touch screen. The images produced are clean and crisp, and the technology avoids the speckle of other laser-based technologies, but so far the device is bigger than those using competing technologies.

A word about eye safety: All of the commercial projection technologies are considered “eye safe” by international standards bodies. But these organizations recognize varying levels of eye safety. The LCOS approaches, which diffuse the laser beams before they leave the projector, are rated Class 1—safe under all conditions of normal use. The scanning-mirror technologies, to date, are rated Class 2—safe because the normal blink response limits exposure.

In the end, there will be room for more than one technology. Some pico projectors will be plug-in, stand-alone devices, intended for use with a laptop computer, an iPhone, an iPod, or even an iPad. For these, size and power consumption won’t matter as much as brightness and overall image quality. Others, intended for use in smartphones, will have to be tiny, extremely power efficient, have decent image quality, and be affordable enough to justify the incremental cost of adding the projector. Right now, the size of the projector package ranges in overall volume from 5 to 18 cubic centimeters. With green-laser diodes coming to market, scanning projectors and some engines could shrink to 3 cm3.

And there’s the size of the projected image. In general, the shorter the distance needed for the projector to produce a large image, the better—up to a point. In the case of an embedded pico projector inside a multimedia player, a 1:1 distance-to-image-size ratio (a projection angle of 53 degrees) is probably sufficient for most applications. The first products on the market have projection angles in the range of 30 to 45 degrees; holographic technology claims a theoretical projection angle of 90 degrees and greater.

Brightness counts too, of course. The brighter the better, right? Not exactly. A very bright source means high power consumption and therefore short battery life. And that’s bad for mobile devices. Depending on the way they are designed into products, the current pico-projector technologies deliver between 2 and 20 lumens of brightness, which can mean a projected and readable image that measures diagonally anywhere from 2.5 to over 250 cm.

The pico projectors available now have resolutions as high as 800 by 600 pixels, equivalent to the SVGA (Super Graphics Video Array) standard. Some projector designers are now working on high-definition resolutions—either 720 by 1280 or 1080 by 1920 pixels, in the wide-screen format of Hollywood movies. None of the contenders has an obvious edge at the moment, but with consumers getting used to high resolution content in other venues, new developments are likely to be announced here soon.

Spoiled by high-quality LCD screens, we’ve come to take rich, vivid colors for granted. And most pico projectors, using either lasers or LEDs for light sources, can project them. But contrast also affects picture quality. Contrast is the dynamic range of a display, from the whitest white to the blackest black. Good contrast is the difference between crisp, dramatic-looking images and washed-out ones. Technologies that use three LEDs or lasers rather than a single light source are tops here, because they simply turn the light source off when it isn’t needed.

Pico projectors will make their first impact in portable consumer electronics. But they won’t stop there. By 2012 we could start seeing them in cars, both in rear-projection video systems and driver head-up displays. Microvision and Light Blue Optics are trying to push laser-based pico projectors into these niches. Lasers are bright enough to overcome daylight. They also have the flexibility to be very dim at night and very bright during the day. Plus, the lasers can be turned off when pixels are not needed, for better nighttime driving visibility. LCDs, on the other hand, are problematic for nighttime driving because the backlight leaches through the liquid crystals, creating a halo effect and reducing contrast.

Further in the future, maybe 3 to 10 years from now, we’ll start seeing pico projectors in eyeglasses and visors, overlaying graphical information on real-world images. For example, with geotagging and location-based services, you might have information about buildings appear as you look at them.

Pico projectors are going to become commonplace. Six or seven years from now, we’ll look back and marvel that people must have been crazy back when they huddled around 3-inch screens.

This article originally appeared in print as “Little Gizmo, Big Picture.”