A rudimentary nanocomputer built from an array of tiny wires could point the way to skirting the limits of Moore’s Law and lead to new kinds of biosensors or microcontrollers for robots. So say scientists and engineers from Harvard and Mitre, a nonprofit R&D company based in Bedford, Mass., and McLean, Va. The team describes its nanowire nanocomputer this week in Proceedings of the National Academy of Sciences.

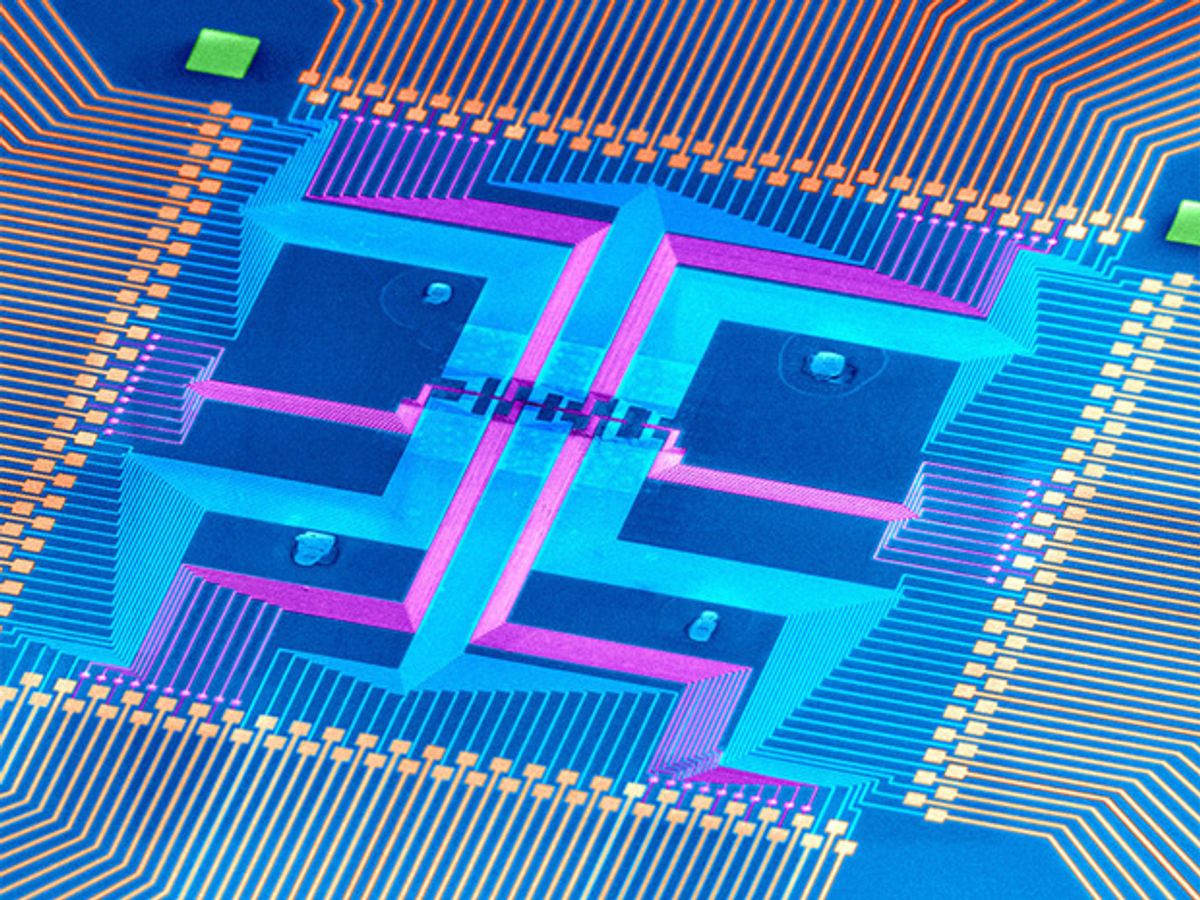

The device is based on 15-nanometer-wide wires with a germanium core and a silicon outer layer. The wires are laid out in parallel on a surface of silicon coated with silicon dioxide, with layers of dielectric material on top and chromium and gold contacts laid perpendicularly across the nanowires. Each point where the contacts cross the nanowires is a programmable transistor node, which can be switched between an active and an inactive state by applying voltage so that the structure forms a “crossbar array.”

The researchers arranged a total of 180 such transistor nodes in six crossbar arrays and divided them into three separate tiles to make a finite-state machine capable of performing arithmetical operations. In one configuration, the first tile does the math, while the second tile holds one bit in memory and the third tile holds a second bit. Chemist Charles Lieber, head of the Harvard team, says more tiles can be added in a Lego-like fashion. The version the team built was a two-bit adder. Four tiles would make a four-bit adder, and so on. A four-by-four array of tiles “could function as a pretty sophisticated microprocessor,” he says.

Researchers concerned with the eventual end of Moore’s Law have been experimenting with nanowires as an alternative to CMOS technology, at least for some applications. Nanowires can easily be grown from a solution on a substrate, using a variety of techniques. However, they’re so small that placing them exactly where they need to be is challenging, and if they accidentally cross each other, they cause a short circuit

Lieber and his team overcame those problems with a technique they call “deterministic nanocombing.” After they’d already grown nanowires on one substrate, they coat another substrate that will form the base of their array with a thin layer of resist, then use electron-beam lithography to remove narrow slots in the resist layer where they want the wires to go. After using a chemical treatment on the wires that makes them more likely to stick to the exposed silicon oxide surface, the researchers take the substrate on which they grew their nanowires and scrape it across the slotted surface of the other substrate. The wires follow the exposed areas, and when they’re in place, the team washes away the remaining resist. Lieber says the approach has led to an improvement of one order of magnitude both in the alignment of the wires and in the number of short circuits, compared with previous techniques.

Instead of having to figure out where the wires ended up in order to connect to them, the researchers count on the statistical likelihood that enough of them are in the right place. “We never have to find the wires afterward. We just assume they’re going to be at these positions,” Lieber says.

The circuits built through this process are small and have low power requirements, which opens up new possibilities for how they can be used. They won’t require bulky power supplies and cooling equipment, which will allow engineers to shrink sensors and microcontrollers. “We’re really going for ‘invisible’ computing and control,” says James Ellenbogen, chief scientist for nanotechnology at Mitre. “You don’t even know that it’s there or that it’s computing, because the energy requirement is so small.”

The Mitre researchers think the technology could be used in biosensors for monitoring a person’s health; because these nanocomputers use little power, they could take far more frequent and detailed measurements than existing devices, says Shamik Das, head of the company’s nanosystems group. Such nanocomputers could also be used for environmental sensors or as controllers for drones and other robotic systems, adds James Klemic, director of Mitre’s nanotechnology laboratory.

André DeHon, an electrical engineer at the University of Pennsylvania, calls this research a step forward for nanocomputing. He’d still like to see the wires packed closer together to increase the transistor density. And he and others are developing new fabrication techniques for contacts, which he says will be needed to make the manufacturing truly bottom-up. “One question is whether or not this will compete with or exceed silicon lithography, or provide the techniques to continue pushing silicon scaling further,” he says.

Lieber says the nanowire device will likely surpass CMOS chips only in very specific applications that benefit from low power consumption and operate at megahertz rather than gigahertz clock rates. But Ellenbogen hopes the research will provide hints for where CMOS technology can be improved. “We think some of the approaches are more generally applicable,” he says.

About the Author

Neil Savage, based in Lowell, Mass., writes about strange semiconductors, unusual optoelectronics, and other things. In the November 2013 issue of IEEE Spectrum, he reported on progress toward making the most powerful MRI in the world.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.