Late last year, the handlers of a newly established service at Argonne National Laboratory spent three weeks running programs on the fifth-fastest supercomputer in the world. All they got to show for it was half a second's simulated combustion in a single cylinder of a diesel engine.

That was plenty.

"To the best of our knowledge, it was the largest diesel engine simulation ever done," says Sibendu Som, a mechanical engineer at Argonne. But, he adds, it was worth it because it nailed down the right degree of detail such simulations need.

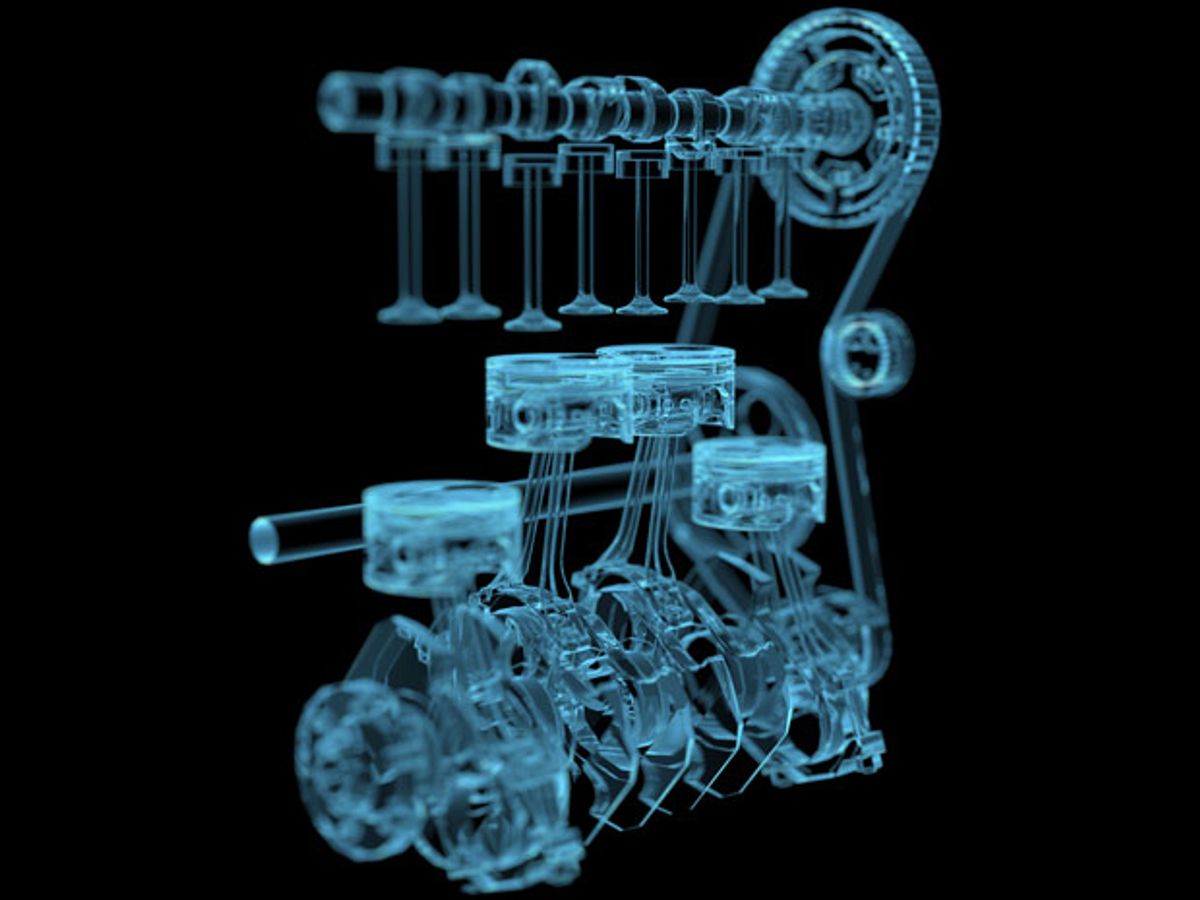

Yes, this blog is called "Cars That Think," but remember, a lot of calculation goes on even before the car hits the road. Engineers want to simulate some of the swirling chaos inside a combustion chamber because it's cheaper and faster than reconfiguring the hardware every time they change a parameter. And they are obligated to simulate some stuff because that's the only way they can observe it at all. Engine blocks are hard to see through.

Besides working out how fine-grained these simulations need to be, Argonne's "Virtual Engine Research Institute and Fuels Initiative," or Verifi, is trying to find ways to improve engine efficiency. Today's best diesels turn up to 43 percent of the energy in fuel into mechanical power. That's according to a 2011 study by the Department of Energy, which estimates that it should be possible to get that figure up to 60 percent.

That will save a lot of fossil fuel, no matter how well electric and hybrid drives work out, because a lot of heavy-duty applications are still going to need internal combustion for decades to come. Exploding fuel makes for an unbeatably high power-to-weight ratio.

The half-second super-simulation broke the combustion area down into cubes just 100 microns on a side. Other, less computationally extravagant simulations worked out the micro-behavior of the burning gases in cells measuring 250 microns and 500 microns, respectively. "When we went from 500 down to 250, we got real improvements in accuracy, but the improvements from dropping from 250 to 100 were small," Som says.

The result is that automakers can expect to do good simulations even if their tools pack less power than Argonne's fearsome Mira, an IBM supercomputer based on the "Blue Gene" architecture. Mira has 48 racks, with 1,024 nodes per rack, using a 1.6 GHz 16-way core processor. All told it has 768 000 cores, 768 terabytes of RAM and a peak computing performance of 10 petaflops. Yes, that comes to 10 quadrillion floating-point operations per second.

Verifi's latest simulation was funded in part by the Department of Energy; it was also done in collaboration with Caterpillar, the farm-equipment company. Cummings Engine and Chrysler are also interested in it, and two other companies, as yet unnamed, are negotiating to use it, too.

Argonne's holding a two-day workshop for engine simulators beginning on 12 November. Som expects from 75 to 100 industry experts to attend.

According to Doug Longman, Argonne's manager of engine combustion research, other national laboratories are also trying to capitalize on their vast computing power. "But not as we do, which is to try to expand the boundaries of the problems we’re working on," he says. He says sister labs in Oak Ridge and Lawrence Livermore are focusing more on sheer volume—"going from hundreds to thousands of simulations—trying to identify variations in tolerance in parts," for instance.

Longman's phrase "expanding boundaries" can be taken literally. To manage that half-second simulation, the engineers had to simplify matters by keeping the boundaries of the combustion area fixed: they modeled only the "close" part of the combustion cycle, when the valves are closed and no gases enter or leave the chamber. It'll be harder to simulate moment-to-moment changes in volume throughout the entire cycle of compression, combustion and exhaust for all the cylinders of an engine while accounting for exchanges of gases among them, as well as other interactions.

To do that, even Mira will need a few extra racks, and maybe some additional air conditioning. But probably not a dedicated hydroelectric power plant.

Philip E. Ross is a senior editor at IEEE Spectrum. His interests include transportation, energy storage, AI, and the economic aspects of technology. He has a master's degree in international affairs from Columbia University and another, in journalism, from the University of Michigan.