Two groups, in Japan and the United States, have reported making see-through circuits out of a new class of semiconductors. Besides holding out the possibility of building displays into the windows of cars and trains, the materials' low cost and low-temperature fabrication may suit them to future applications that don't need transparency, notably roll-up electronic displays.

Standard silicon-based techniques can't compete in this area, because even if they could be made flexible, their processing temperatures, generally around 250 °C, are so high they would melt any plastic substrate holding the silicon in place. To get around the problem, several academic and corporate laboratories are developing pentacene and other organic semiconductors—so called because they consist of carbon, hydrogen, and oxygen.

But although organic transistors can be processed at low temperatures and even printed like ink, they don't let electrons and other charge carriers move around very quickly; therefore, they perform poorly. Besides, organic materials tend to be thermally and chemically unstable.

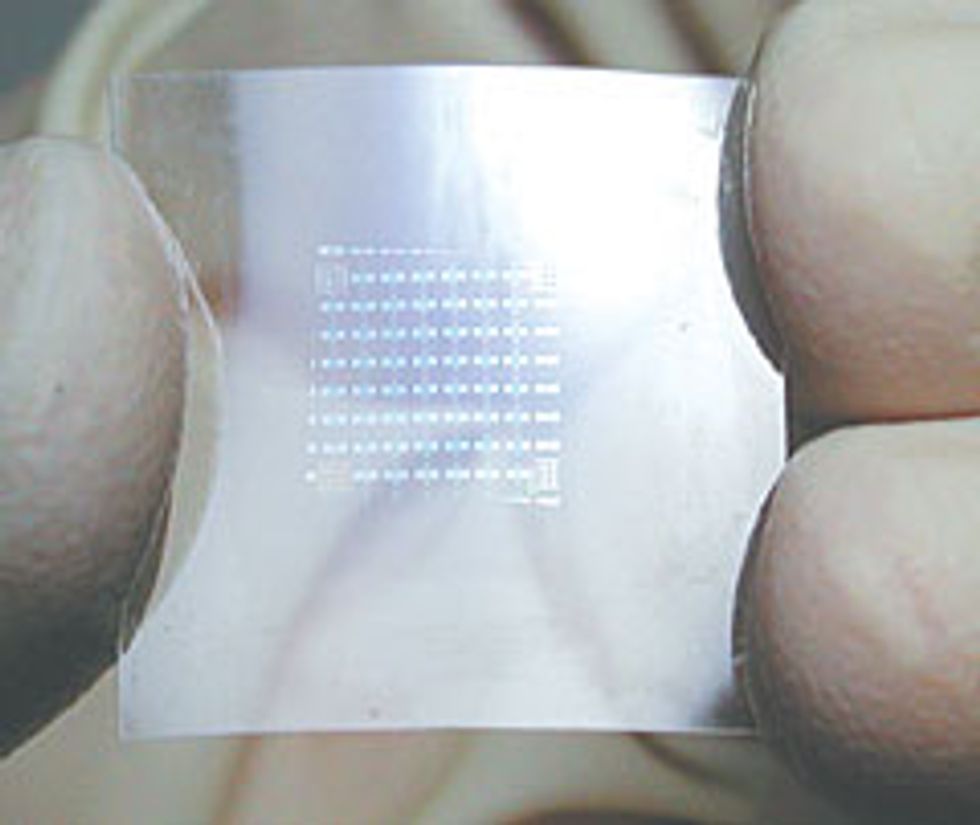

Outflexing The Competition: A new class of thin-film transistors barely shows itself on this flexible plastic substrate, produced by a materials science group at the Tokyo Institute of Technology's laboratory in Yokohama, Japan. Low-temperature fabrication makes the plastic substrate practical.

Hideo Hosono, the leader of a group of materials scientists at the Tokyo Institute of Technology, sought a way around these problems by examining a different class of materials: amorphous oxides. The name was given them because they lack a crystalline structure. He made an educated guess that the overlapping electron orbits of the heavy metals in the materials would let electrons zip through, and he mounted an Edisonian quest for the best compounds. He winnowed them down to a handful that could be deposited at room temperatures yet yield high performance.

In the 25 November 2004 issue of Nature, Hosono's group described transistors made of an amorphous film of indium gallium zinc oxide (or a-IGZO). The researchers blasted an ingot of indium alloy with pulses of laser light, spraying a jet of vaporized semiconductor onto a flexible sheet of polyethylene terephthalate, a common plastic, at room temperature. They then completed the see-through transistors with standard photolithography techniques and transparent interconnects, such as the ones found in flat-panel displays.

The semiconductor is n-type, meaning that electrons carry charges through it. The speed at which the electrons move in the device—called the field-effect charge carrier mobility—is key, because it limits how fast a transistor can switch. In a-IGZO devices, the mobility is 6-10 square centimeters per volt-second, about five times that in similar organic thin-film transistors and more than seven times that of the hydrogenated amorphous silicon in flat-panel displays today.

Hosono showed IEEE Spectrum a specimen in his Yokohama office [see photo]. The thin-film transistor circuitry could be seen only with difficulty on the bendable plastic. Hosono noted that repeated bending had little effect on transistor performance. The transistors have also proved that they could take some heat, staying stable even at temperatures as high as 120 °C. Hosono has turned over development of the a-IGZO devices to a Japanese electronics company, which he declines to identify.

Weeks after Hosono's report, a group on the other side of the Pacific announced that it had made even faster transparent transistors, with mobilities of up to 50 cm2/ V-s. John F. Wager, an electrical engineering professor at Oregon State University, led a group, including researchers from Hewlett-Packard Co.'s Corvallis, Ore., laboratory, in studies of a different amorphous oxide semiconductor, zinc tin oxide. Wager's group also employed a more manufacturing-friendly deposition technique, called sputtering, in which RF energy turns metal into vapor, which then forms a film on a substrate.

Carrier mobilities have already matched what many believe is the theoretical speed limit for organic transistors

Because Wager baked his devices for an hour at either 300 or 600 °C, he had to build them on glass instead of plastic. But in work to be published this month in the Journal of Applied Physics, Wager says he has brought the temperature to well below 100 °C, making plastic-backed circuits possible, at the cost of reducing mobility to about 8 cm2/ V-s.

"In the first application," Wager says, "transparency may be an irrelevant detail," eclipsed by the advantages of low-temperature fabrication and carrier mobilities so fast that they have already matched what many believe is the theoretical speed limit for organic transistors.

"If you track mobility, it seems that progress [in organic transistors] has sort of stalled out," says John A. Rogers, a chemist at the University of Illinois, Urbana-Champaign, who has made devices from Wager's semiconductor. He adds that amorphous oxides and organic semiconductors are not the only runners in this race. His lab has made faster, though visible, devices by printing ribbons of silicon on plastic.