27 September 2012—Researchers at the University of Illinois at Urbana-Champaign and Tufts University say they have invented functional electronic implants that can dissolve after programmable time periods. To demonstrate the system, which could aid in healing during the first few crucial days after an operation, they implanted one in a rat. It created a temporary temperature increase to sterilize a wound, and then it dissolved after 15 days. The researchers reported the development this week in the journal Science.

Biomedical researchers are turning to the idea of “programmable degradation” because it is difficult to develop materials that remain compatible with human tissue over the long term. Medical implants or drug-delivery systems that do their work and then disappear are ideal. To develop the electronic implants, the researchers encased them in silk. That material’s characteristics, particularly its crystallinity, can be adjusted so that its degradation time can be anywhere from seconds to years.

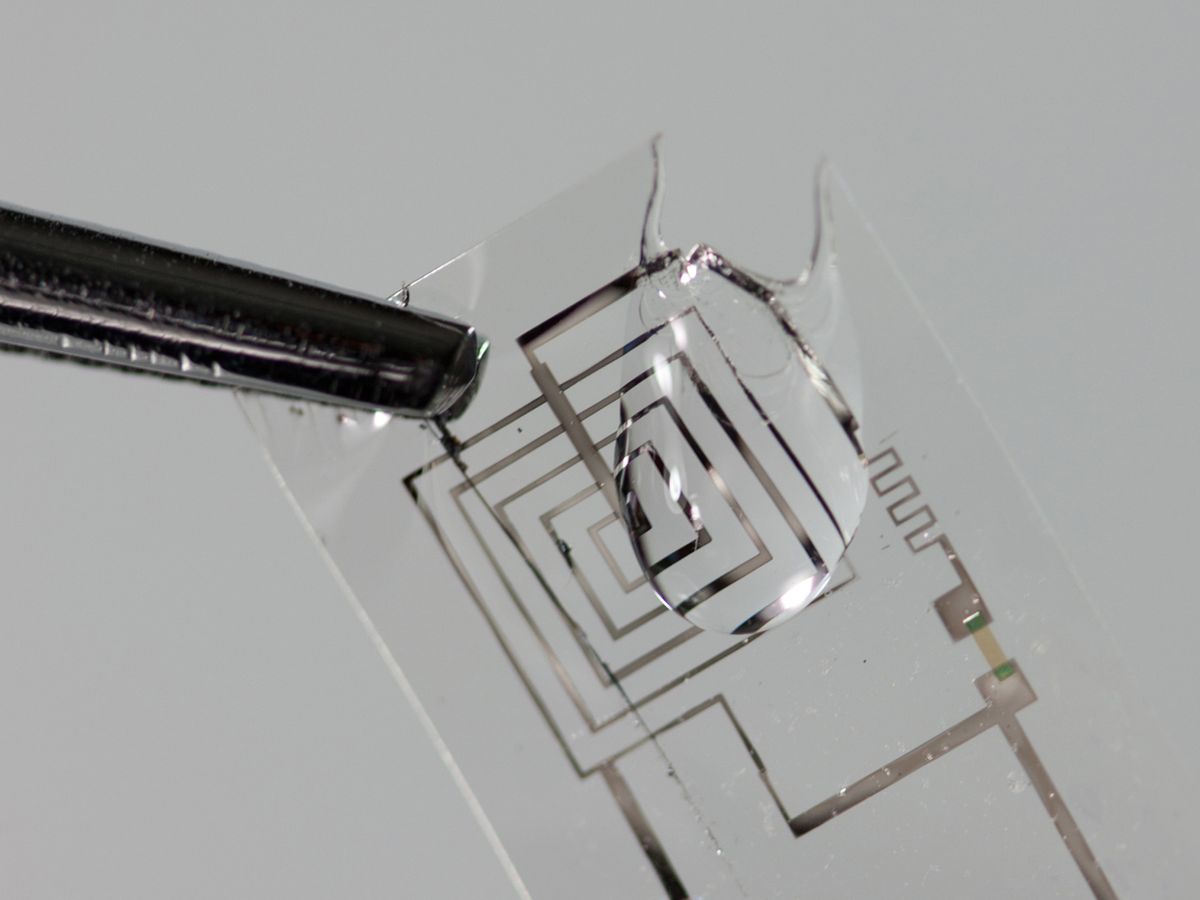

The electronics inside the silk were based on nanometers-thick sheets or ribbons of silicon, called silicon nanomembranes. The materials have been previously used to make experimental transistors, diodes, complementary logic devices, and photocells for flexible surfaces. Whereas a conventional silicon wafer or a chip would take about a thousand years to dissolve in biofluids, says John A. Rogers, who led the research at the University of Illinois, a nanomembrane is gone in a couple of weeks.

Working with the team at Illinois, Tufts researchers provided expertise on silk and carried out the animal experiments. Analytical modeling was done at Northwestern University in collaboration with Dalian University of Technology, in China, and a University of Arizona clinician identified the heat-therapy application.

While there have been no human trials yet, the component materials of the system are found in implants that have been approved by government regulators for other medical uses, Rogers points out. Silk is approved for sutures, magnesium is used for intravascular stents, and silicon is used for drug-delivery systems. “You have to do trials, because biology is complicated,” Rogers says, “but the materials are not complicated.”

The researchers tested a host of such transient components like inductors, capacitors, resistors, diodes, and transistors. All the components disintegrated and dissolved when immersed in deionized water. The materials and fabrication techniques may be used to make components for electronic systems in complementary metal-oxide semiconductor (CMOS) logic.

“Here is this toolbox that you can make anything with,” says Christopher J. Bettinger, a biomaterials researcher at Carnegie Mellon University who was not involved in the research, adding that the work was a remarkable feat of integration that neatly combined pieces from several areas. It’s also a very flexible system, he says; for example, the silk substrate could be swapped with other biodegradable polymers.

Jeffrey Borenstein, a researcher at the Charles Stark Draper Laboratory in Massachusetts, was also impressed. “As a general demonstration, this is very powerful,” he says. “When it comes to specific applications, you will have to evaluate how each of these materials performs inside the body.”

One challenge ahead could be finding additional ways to power the implants. The first version was powered by RF energy, but RF coils “are just very sensitive to orientation,” Bettinger says, adding that if you have a patient who moves around, it might change the power requirements.

The Illinois researchers, however, might have something in their favor. There is a synergy, Rogers says, between their work and the multibillion-dollar semiconductor industry that isn’t immediately obvious. As with conventional CMOS devices, with transient electronics, thinner is better. “I think we will be able to bootstrap off of advances in conventional electronics,” he says.