We humans are continuing to send robots farther and farther away from Earth, even as we ask them to deal with more and more complex situations here at home, and both of these things mean that autonomy is getting increasingly critical. Robots encounter all kinds of unexpected complications if they’re operating in unfamiliar environments, and we want them to minimize their reliance on active human involvement. Autonomy is just the start: the goal is the ability to learn and evolve, and researchers at the University of Oslo in Norway are developing a system that can print out customized robots to tackle any situation it faces.

Professor Kyrre Glette, from the Robotics and Intelligent Systems research group, describes the overall concept of this system:

“In the future, robots must be able to solve tasks in deep mines on distant planets, in radioactive disaster areas, in hazardous landslip areas and on the sea bed beneath the Antarctic. These environments are so extreme that no human being can cope. Everything needs to be automatically controlled. Imagine that the robot is entering the wreckage of a nuclear power plant. It finds a staircase that no-one has thought of. The robot takes a picture. The picture is analysed. The arms of one of the robots is fitted with a printer. This produces a new robot, or a new part for the existing robot, which enables it to negotiate the stairs.”

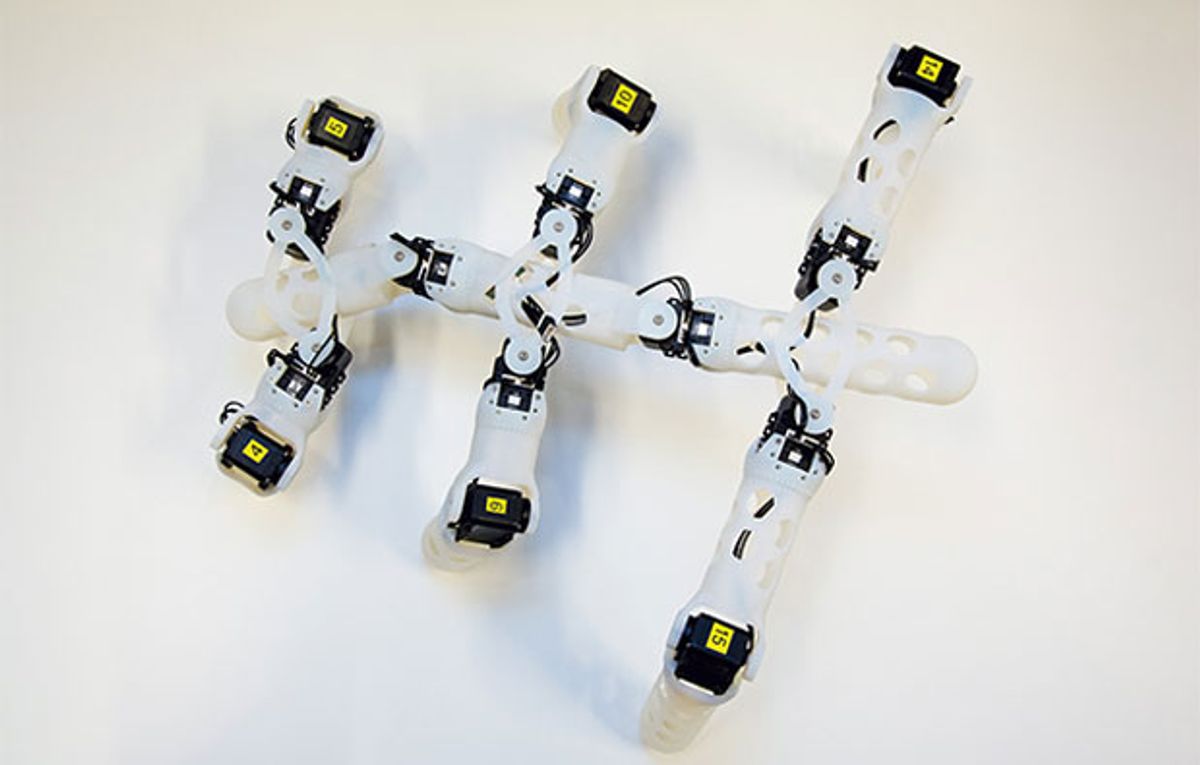

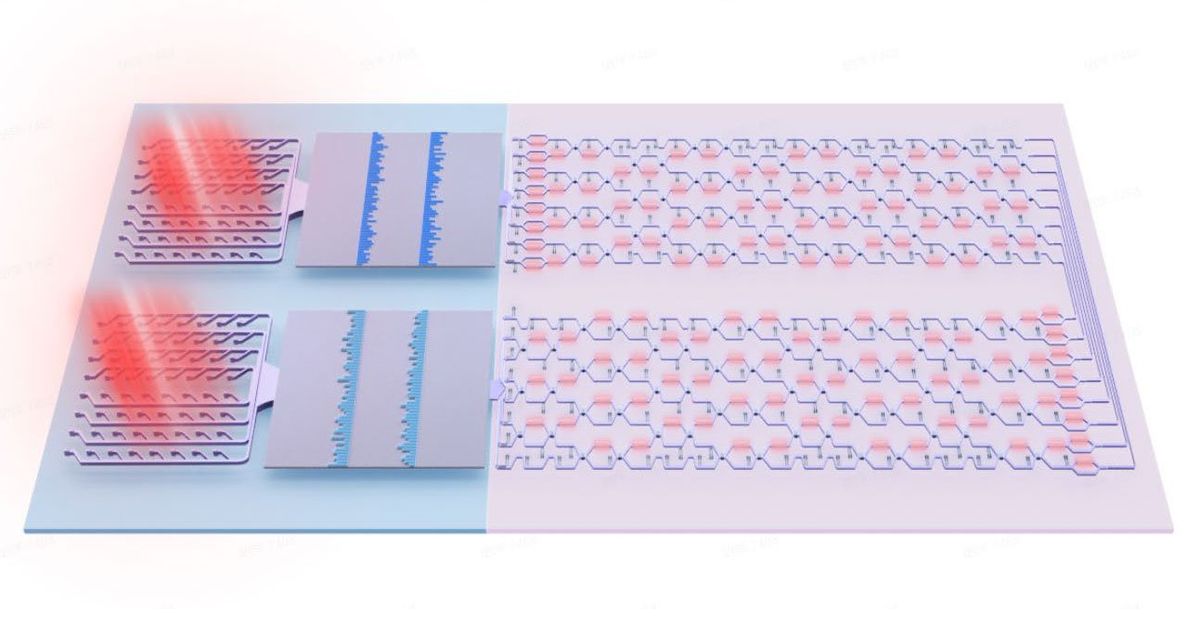

Several years ago, we saw a similar idea from University of Pennsylvania researchers, where they had one robot building other robots out of spray foam. The University of Oslo team is using a very expensive 3D printer to be much more precise with their designs. Inputs to the design of the robots include desired size, speed, efficiencies, and also capabilities, like being able to climb or turn. In response, the system will produce a whole bunch of different robots, each with unique body shapes, legs, and joints. It then sets them against each other in fights to the death (in simulation), and finally, sends the specs of the winning robot off to the 3D printer for production.

Recognizing that simulation often bears little resemblance to the world that’s being simulated, the researchers are asking the system to make a handful of robots that it thinks will be equally good at solving a task in a real environment. In one example, there were three robots with four legs, plus one with three legs and one with six legs. At the moment, the robots are being evaluated on real obstacle courses to see which one is actually better, but eventually, it’ll all be autonomous, whether in simulation or with the system running live trials of several different designs and using the results to improve both the next generation of robots and its evolutionary algorithms.

In principle, we’re very much in favor of robots that design and build other robots. But in all seriousness, this is a crucial capability for robots that are operating autonomously, far from human support. Imagine if the Mars rovers had been packing little 3D printers that they were able to use to print tools to free themselves from deep sand, or covers to help prevent wheel punctures. Being able to adapt to new and unexpected environments is one of the things that makes humans so successful, and it’s a trick that robots desperately need to learn.

This research builds off of earlier work from the University of Oslo, most notably (and hilariously) this robot named Henriette that would teach itself to run like a chicken:

[ University of Oslo ] via [ 3DPrint ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.